Polylactic acid-based thermoplastic polyurethane modified polylactic acid composite material and preparation method and application thereof in 3D printing consumables

A technology of thermoplastic polyurethane and composite materials, applied in the direction of additive processing, etc., can solve problems such as agglomeration and inability to spin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

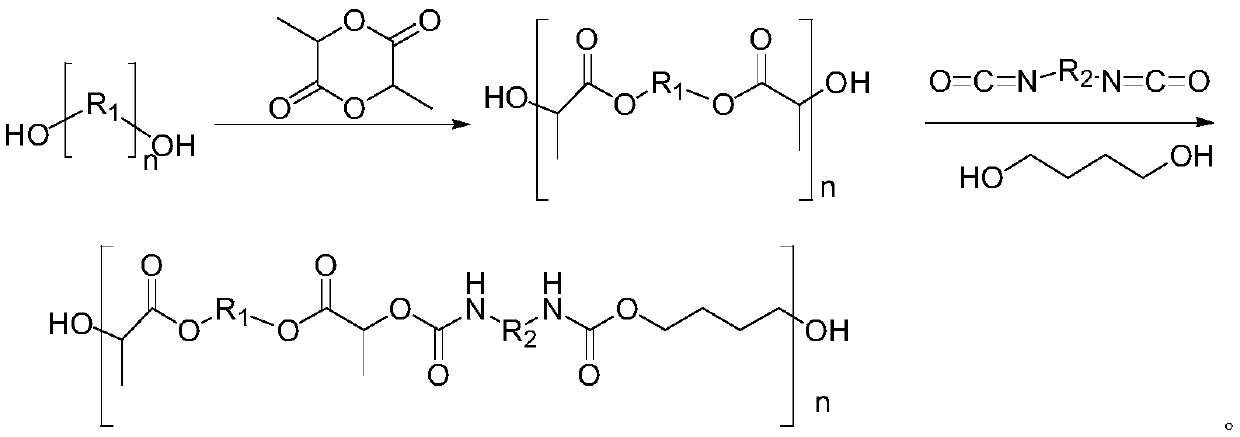

[0042] The invention discloses a preparation method of a polylactic acid-based thermoplastic polyurethane modified polylactic acid composite material, which comprises the following steps:

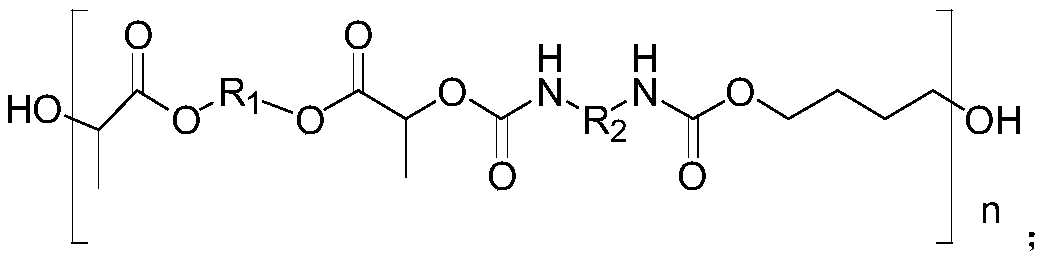

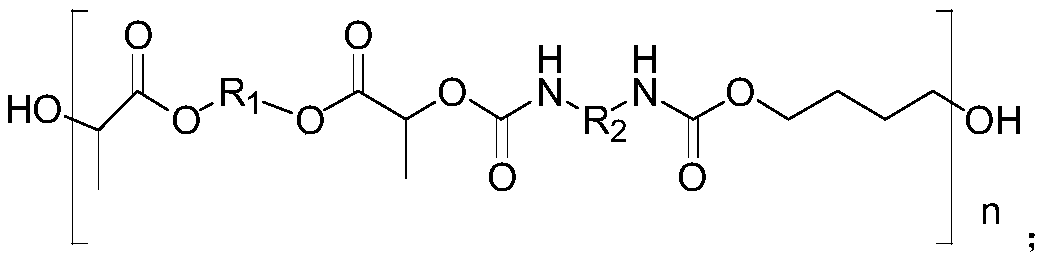

[0043] 1) Preparation of modified polylactic acid polyol: take polyether polyol or polyglycol, lactide and the first catalyst to obtain modified polylactic acid polyol through ring-opening polymerization; wherein, the modified polylactic acid polyol Have the following general chemical structure formula;

[0044] Wherein, the polyglycol comprises polyethylene glycol or polypropylene glycol, and the polyether glycol comprises polytetrahydrofuran;

[0045] The first catalyst includes one or more of zinc compounds such as zinc powder, zinc oxide, zinc acetate, and diethyl zinc, or tin compounds such as dibutyltin dilaurate, stannous octoate, stannous chloride, and tin lactate. .

[0046] 2) Preparation of polylactic acid-based thermoplastic polyurethane: react the modified polylactic acid p...

Embodiment 1

[0068] This embodiment discloses a preparation method of polylactic acid-based thermoplastic polyurethane, which comprises the following steps:

[0069] 1) Preparation of modified polylactic acid polyol: take 130 parts of polytetrahydrofuran (number average molecular weight 650), and 270 parts of lactide are pre-dehydrated in different devolatilization kettles, and then mixed with 0.02 parts of catalyst (diethyl zinc) Mix evenly in the reactor, heat the reactor to 120-180°C and react for 3-5 hours, and then perform 1-2 hours of devolatilization treatment to obtain modified polylactic acid polyol (wherein, the number-average molecular weight of the modified polylactic acid polyol 2000).

[0070] 2) Preparation of polylactic acid-based thermoplastic polyurethane: take the modified polylactic acid polyol prepared in step 1), 1,6-hexamethylene diisocyanate and butanediol according to the molar ratio of 1:3.6:2.6, and the second catalyst (dilauric acid Dibutyltin) is injected into...

Embodiment 2~6

[0073] Examples 2-6 (changes according to the type of polyether polyol or polyglycol, and diisocyanate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com