A red gold alloy for firing high-temperature transparent enamel and its preparation method

An alloy and transparent technology, applied in the field of red gold alloy and its preparation, can solve the problems of jewelry production, affecting the production progress and cost of enterprises, brittle metal substrate, etc., and achieves good high temperature oxidation resistance, excellent cold working performance, crystallinity fine grained effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

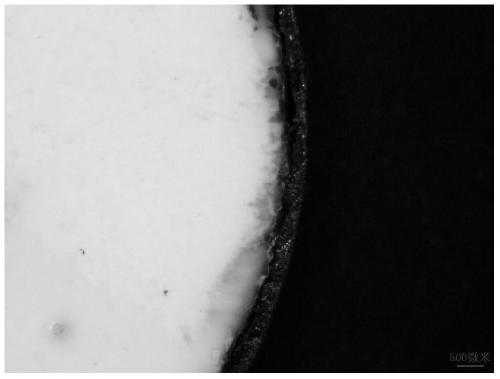

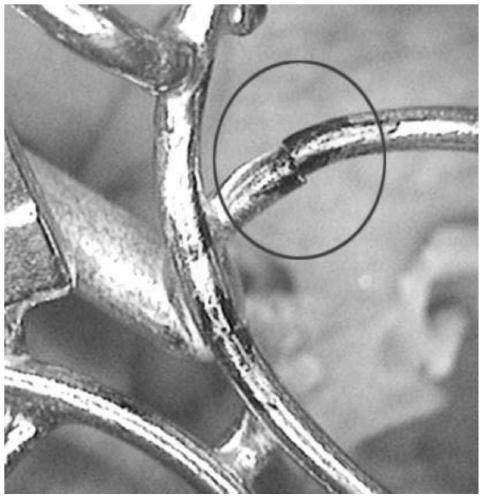

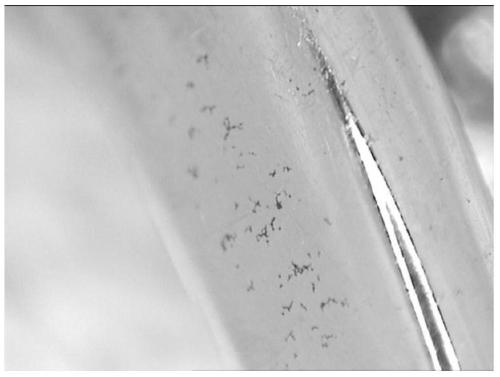

[0035] The preparation method of the red gold alloy for firing high-temperature transparent enamel, the steps are:

[0036] 1) Melting the raw materials under a protective atmosphere;

[0037] 2) After all the materials are melted, adjust the temperature of the molten metal and cast to obtain ingots;

[0038] 3) After the ingot is rolled, it is annealed.

[0039] Preferably, in step 1), the protective atmosphere is commercially pure argon.

[0040] Preferably, step 1) is: rolling pure gold into thin sheets, wrapping silver-scandium alloy, silver-palladium alloy, silver-copper alloy, copper-zinc alloy, copper-silicon alloy, pure silver with it, putting it into a graphite crucible, Melting is carried out by induction heating, and the melting temperature is 1020-1040°C;

[0041] Preferably, in step 2), the temperature of the molten metal is adjusted to 1010-1030°C.

[0042] Preferably, the annealing treatment is: annealing at 700-800° C. for 3-10 minutes.

Embodiment 1

[0045] The red gold alloy used for firing high-temperature enamel of the present embodiment consists of the following components by mass percentage:

[0046] 75.20wt% gold, 22.87wt% copper, 1.07wt% silver, 0.53wt% zinc, 0.30wt% palladium, 0.015wt% silicon, 0.013wt% scandium, 0.0008wt% boron, and other unavoidable impurities.

[0047] The preparation method of the present embodiment comprises the following steps:

[0048] Smelting in a vacuum induction furnace, the mass percentages of the raw materials are: 1.3wt% copper-scandium alloy, 6wt% copper-palladium alloy, 7.3wt% copper-silver alloy, 1.5wt% copper-silicon alloy, 0.7wt% pure silver, 7.6wt% copper-zinc alloy, 0.4wt% copper-boron alloy, 75.2wt% pure gold. Put the above materials into the graphite crucible in turn, fill it tightly and close the furnace cover, evacuate to 4.4Pa, and fill it with industrial pure argon to 1.01atm. Start induction heating for smelting, and the smelting temperature is 1030-1040°C. After the ...

Embodiment 2

[0056] The red gold alloy used for firing high-temperature enamel of the present embodiment consists of the following components by mass percentage:

[0057] 75.0wt% gold, 1.13wt% silver, 23.06wt% copper, 0.51wt% zinc, 0.26wt% palladium, 0.028wt% silicon, 0.020wt% scandium, 0.0010wt% boron, and other unavoidable impurities.

[0058] The preparation method of the present embodiment comprises the following steps:

[0059] Smelting in a vacuum induction furnace, the mass percentages of the raw materials are: 2wt% copper-scandium alloy, 5.1wt% copper-palladium alloy, 6.5wt% copper-silver alloy, 2.8wt% copper-silicon alloy, 0.8wt% pure silver, 7.3wt% copper-zinc alloy, 0.5wt% copper-boron alloy, 75.0wt% pure gold. Put the above materials into the graphite crucible in turn, fill it tightly and close the furnace cover, evacuate to 4.7Pa, and fill it with industrial pure argon to 1.02atm. Start induction heating for smelting, and the smelting temperature is 1020-1030°C. After the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com