Bone screw covered with soft material

A soft material and bone screw technology, applied in the field of bone screws, can solve the problems of secondary trauma to bone tissue, inability to guarantee non-rotation, secondary injury to patients, etc., achieving good biocompatibility, saving time and effort, and saving operation time. , the effect of shortening the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

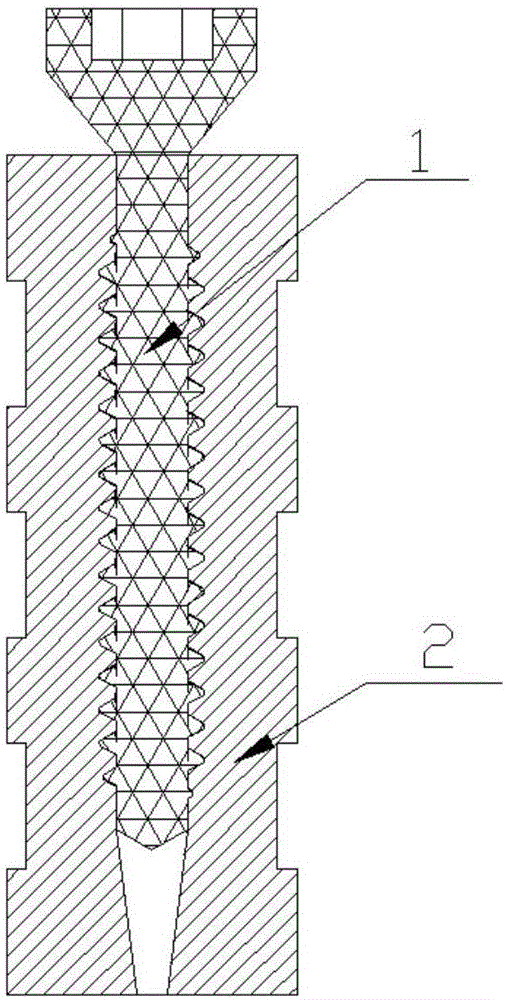

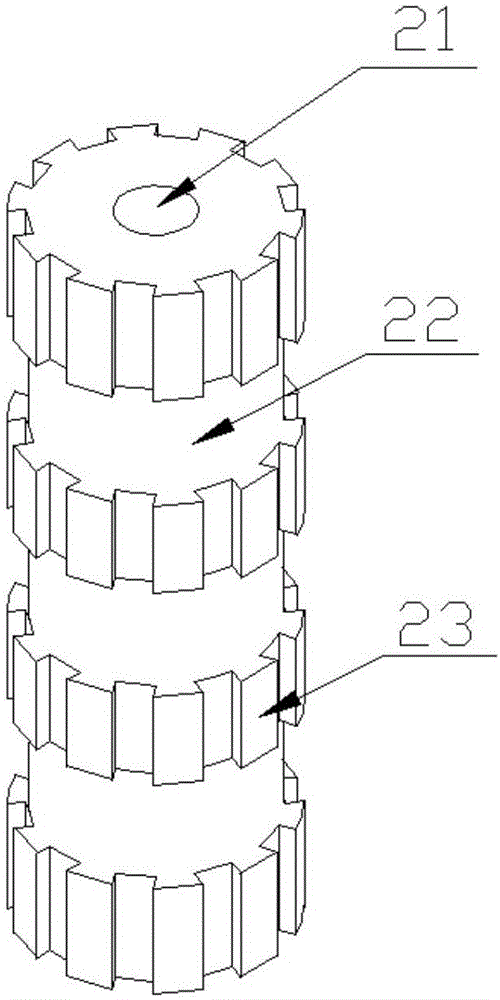

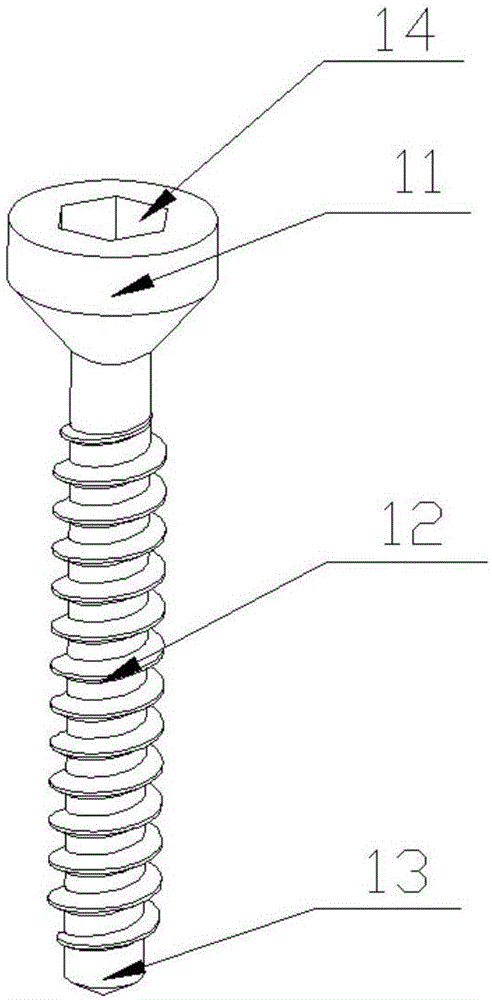

[0027] combine Figure 1-3 , the soft material-coated bone screw assembly of the present invention is composed of a bone nail body 1 and an outer soft body 2, the outer soft body 2 contains a cavity 21 in the center, and the cavity is a rounded table cavity; The outer surface of the outer soft body 2 is equidistantly provided with a smooth part 22 and protruding serrations 23, a smooth part 22 is provided between every two protruding serrations 23, and the number of protruding serrations 23 is n, so The number of the 22 smooth parts is n-1, and the n is a positive integer. The protruding serrations 23 of the outsourcing soft body 2 can make the bone screw assembly have a force in the horizontal direction, preventing the bone screw assembly from turning left and right when fixing a broken bone; the rounded cavity contained in the center of the outsourcing soft body 2, The extension line of the cavity 21 forms an included angle of 15°-20° with the vertical centerline of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com