PVDF/li1.3al0.3ti1.7(po4)3 solid dual-phase electrolyte film material and preparation method

A technology of electrolyte film and film material, which is applied in the field of solid dual-phase electrolyte film and its manufacturing, can solve the problems of high cost, long process flow, and complicated operation, and achieve the effects of enhanced retention capacity, simple synthesis process, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

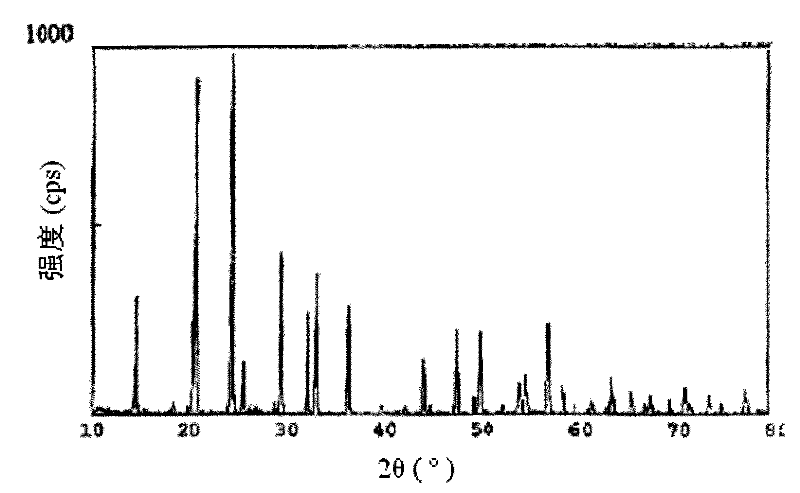

[0016] Li(CH 3 COO)·2H 2 O and Al(NO 3 ) 3 9H 2 O is added to ethylene glycol methyl ether, and after it is completely dissolved, add PO(OC 4 h 9 ) 3 , and then add Ti(OC 4 h 9 ) 4 And keep stirring, Li(CH 3 COO)·2H 2 O, Al(NO 3 ) 3 9H 2 O, Ti(OC 4 h 9 ) 4 , PO(OC 4 h 9 ) 3 According to the ratio of the amount of substances added, the ratio of the amount of the substance is 1.35:0.3:1.7:3, the obtained solution is heated at a constant temperature of 140°C for 4 hours to form a gel, and the dry gel is calcined in the air at 850°C for 4 hours, and after cooling in the furnace Ball milling and sieving to obtain Li with a particle size of less than 2 μm 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 powder.

[0017] Mix and stir PVDF and DMAC to prepare a solution containing 20% PVDF, and use DMAC to dissolve Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 Powder dispersion, adjusted to contain 50% Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 slurry, then press Li 1.3 al 0.3 Ti 1.7 (PO 4 )...

Embodiment 2

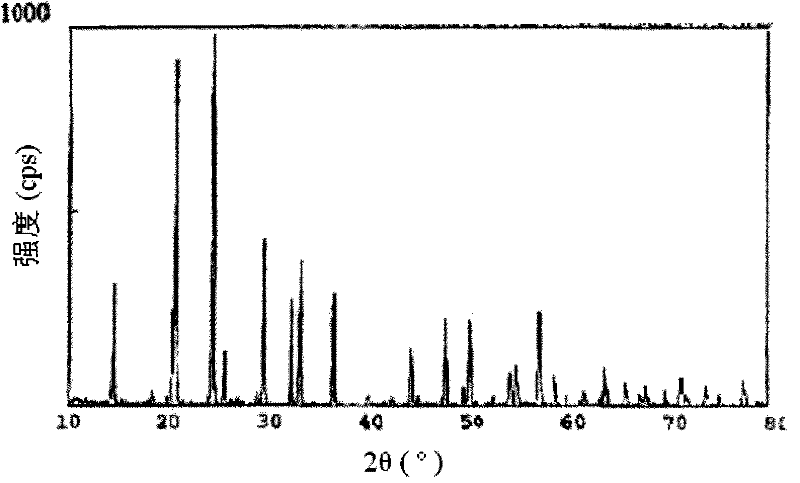

[0020] Li(CH 3 COO)·2H 2 O and Al(NO 3 ) 3 9H 2 O is added to ethylene glycol methyl ether, and after it is completely dissolved, add PO(OC 4 h 9 ) 3 , and then add Ti(OC 4 h 9 ) 4 And keep stirring, Li(CH 3 COO)·2H 2 O, Al(NO 3 ) 3 9H 2 O, Ti(OC 4 h 9 ) 4 , PO(OC 4 h 9 ) 3 According to the ratio of the amount of substances added, it is 1.50:0.3:1.7:3, and the obtained solution is heated at a constant temperature of 120°C for 4 hours to form a gel, and the dry gel is calcined in the air at 810°C for 6 hours. Ball milling and sieving to obtain Li with a particle size of less than 2 μm 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 powder.

[0021] Mix and stir PVDF and DMAC to prepare a solution containing 10% PVDF, and use DMAC to dissolve Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 Powder dispersion, adjusted to contain 50% Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 slurry, then press Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 PVDF-DMAC solution and Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 - DMAC...

Embodiment 3

[0024] Li(CH 3 COO)·2H 2 O and Al(NO 3 ) 3 9H 2 O is added to ethylene glycol methyl ether, and after it is completely dissolved, add PO(OC 4 h 9 ) 3 , and then add Ti(OC 4 h 9 ) 4 And keep stirring, Li(CH 3 COO)·2H 2 O, Al(NO 3 ) 3 9H 2 O, Ti(OC 4 h 9 ) 4 , PO(OC 4 h 9 ) 3 According to the ratio of the amount of substances added, it is 1.45:0.3:1.7:3, and the obtained solution is heated at a constant temperature of 140°C for 2 hours to form a gel, and the dry gel is calcined in air at 875°C for 3 hours. Ball milling and sieving to obtain Li with a particle size of less than 2 μm 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 powder.

[0025] Mix and stir PVDF and DMAC to prepare a solution containing 15% PVDF, and use DMAC to dissolve Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 Powder dispersion, adjusted to contain 30% Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 slurry, then press Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 PVDF-DMAC solution and Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 - DMAC slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com