a licuvo 4 Nanofiber preparation method and its products and applications

A technology of nanofibers and organic solvents, applied in the field of preparation of LiCuVO4 nanofibers, can solve the problems of large particle size, small specific surface area, and uneven structure of electrode materials, and achieve small size, high specific surface area, and improved structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Get vanadyl acetylacetonate (0.2mol), lithium acetate dihydrate (0.2mol) and copper acetate monohydrate (0.2mol), add in 5mL N-N dimethylformamide solution, then add 0.4g polyacrylonitrile, at 40 Under the condition of ℃, stir until dark blue homogeneous solution, which is the spinning solution.

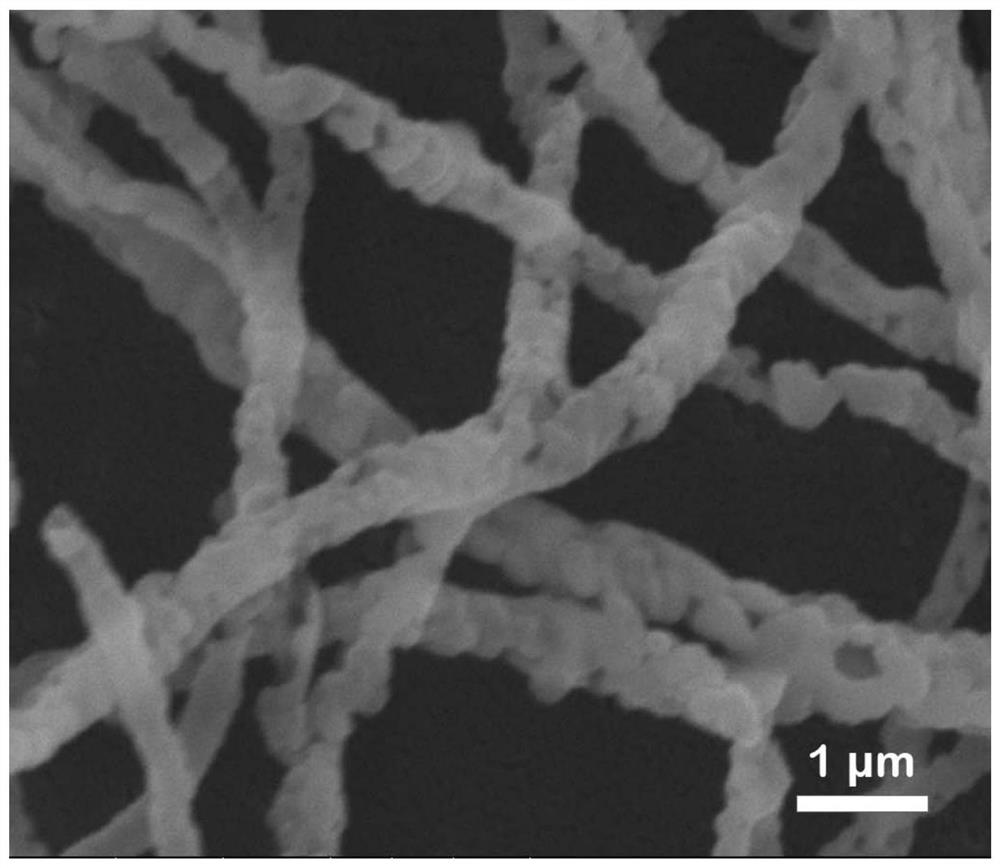

[0024] The resulting spinning solution was injected into a 10mL disposable syringe, an applied voltage of 8kV was set, and the pushing speed was set at 0.5 mm / min for electrospinning. After spinning, a light blue nanofiber precursor was obtained.

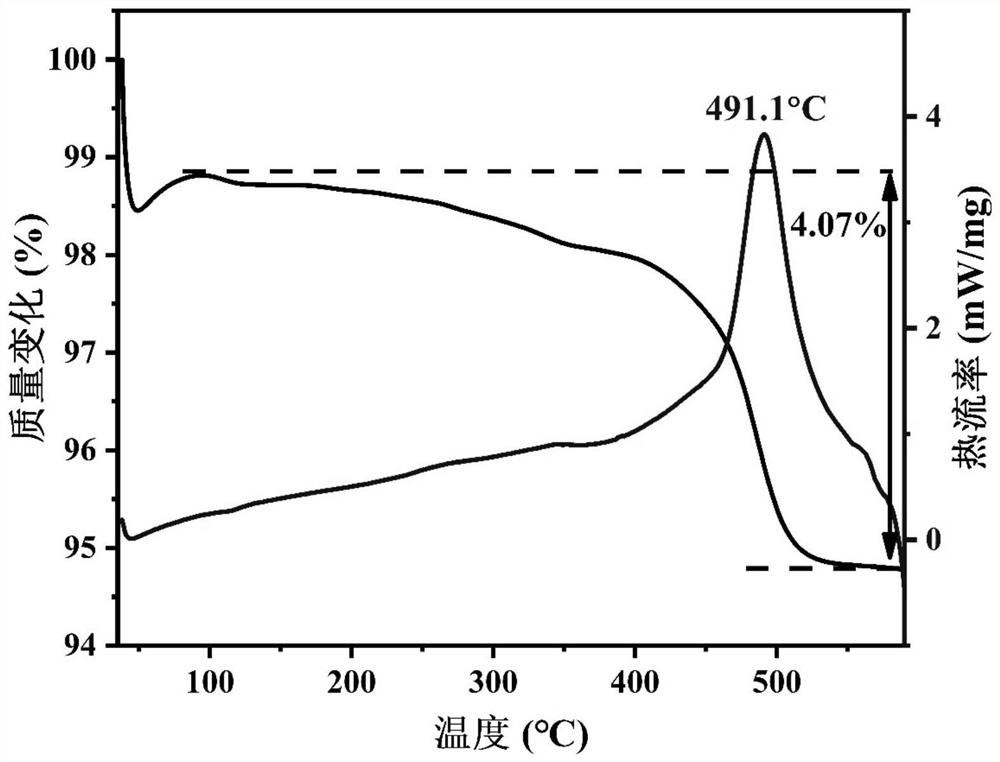

[0025] The obtained precursor was heat-treated in air at 250 °C for 40 min, and the heating rate was 3 °C / min. Then, the cured material was continuously calcined in the air at 450°C for 0.5h and the heating rate was 5°C / min to obtain carbon-containing LiCuVO 4 Nanofiber, its carbon content was measured to be 4.07%.

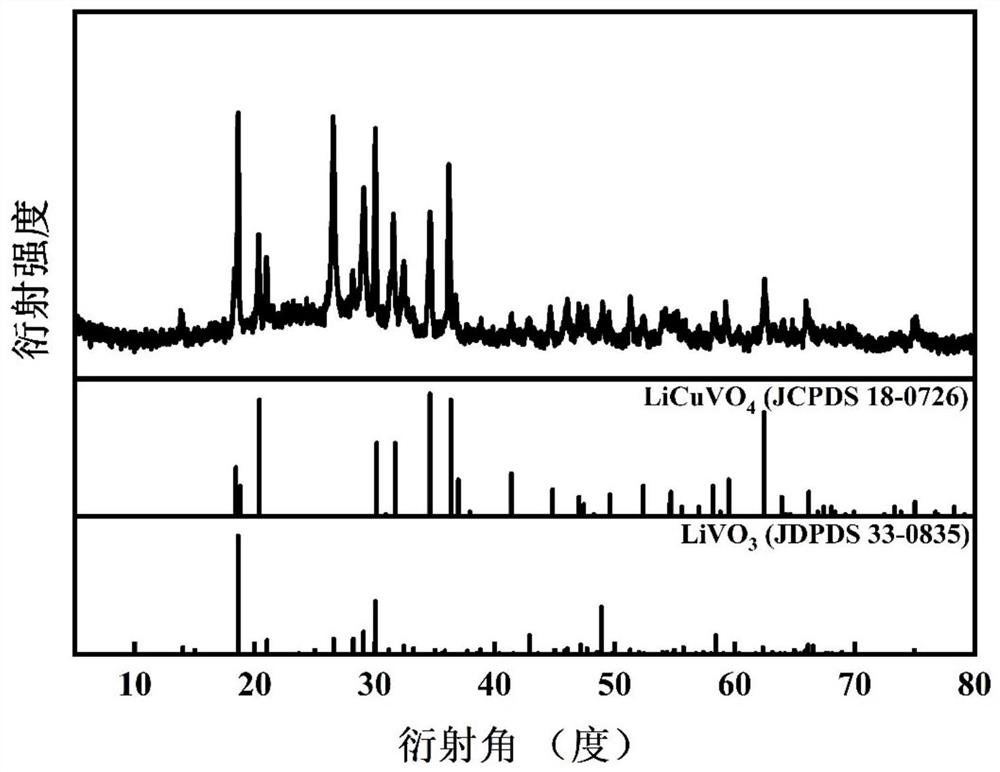

[0026] The resulting carbon-containing LiCuVO 4 The nanofibers were analyzed by XRD, and the results were as follo...

Embodiment 2

[0036] Take vanadyl acetylacetonate (0.2mol), lithium acetate dihydrate (0.2mol) and copper acetate monohydrate (0.2mol) and add them to 5mL N-N dimethylformamide solution, then add 0.3g polyacrylonitrile, at 40℃ Under the condition of stirring until dark blue homogeneous solution, which is the spinning solution.

[0037] The spinning solution was injected into a 10mL disposable syringe, an 8kV voltage was applied, and the pushing speed was set at 0.5 mm / min for electrospinning. After the spinning was completed, a light blue nanofiber precursor was obtained.

[0038] The obtained precursor was heat-treated in air at 250 °C for 40 min, and the heating rate was 3 °C / min. Then, the solidified material was continuously calcined in the air at 450°C for 0.5h, and the heating rate was 5°C / min to obtain carbon-containing LiCuVO 4 Nanofiber, its carbon content was measured to be 3.83%.

[0039] According to the performance test method in embodiment 1, the carbon-containing LiCuVO pre...

Embodiment 3

[0041] Get vanadyl acetylacetonate (0.2mol), lithium acetate dihydrate (0.2mol) and copper acetate monohydrate (0.2mol), add in 5mL N-N dimethylformamide solution, then add 0.5g polyacrylonitrile, at 45 Under the condition of ℃, stir until dark blue homogeneous solution, which is the spinning solution.

[0042] The resulting spinning solution was injected into a 10mL disposable syringe, an applied voltage of 10kV was set, and the pushing speed was set at 0.7 mm / min to carry out electrospinning. After the spinning was completed, a light blue nanofiber precursor was obtained.

[0043] The obtained precursor was heat-treated in air at 300 °C for 30 min, and the heating rate was 5 °C / min. Then, the cured material is continuously calcined in the air at 480°C for 0.5h and the heating rate is 3°C / min to obtain carbon-containing LiCuVO 4 Nanofiber, its carbon content was measured to be 4.58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com