Patents

Literature

31results about How to "Uniformly distributed refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ausferrite ductile cast iron grinding ball

ActiveCN104152792AHighlight substantive featuresImprove absorption rateGrain treatmentsAlloyDuctile iron

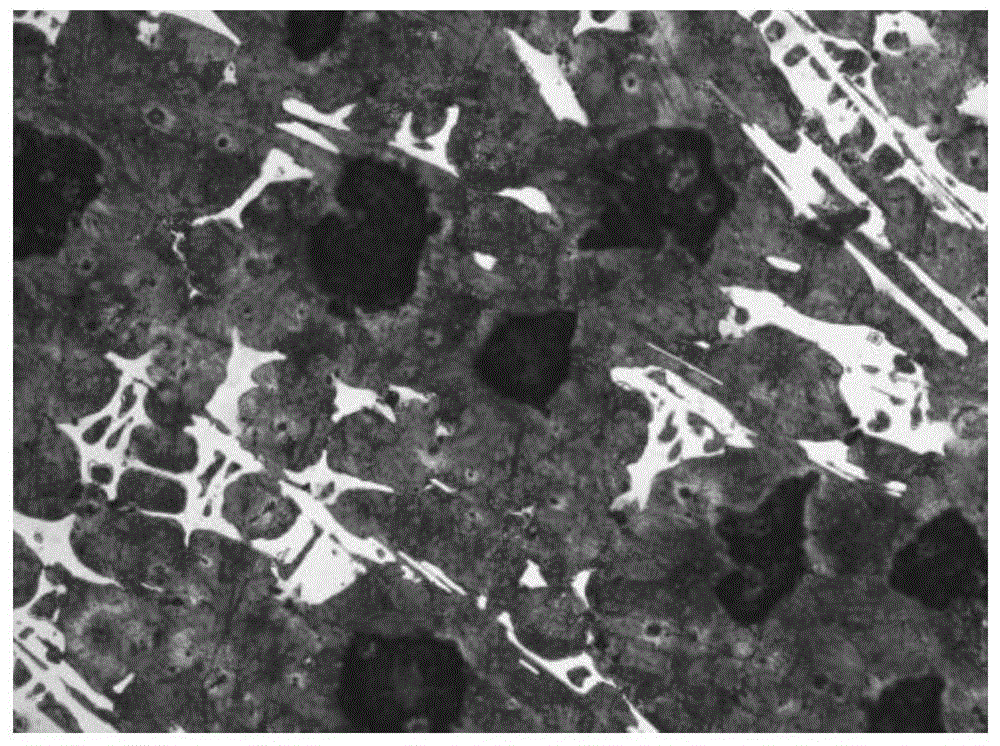

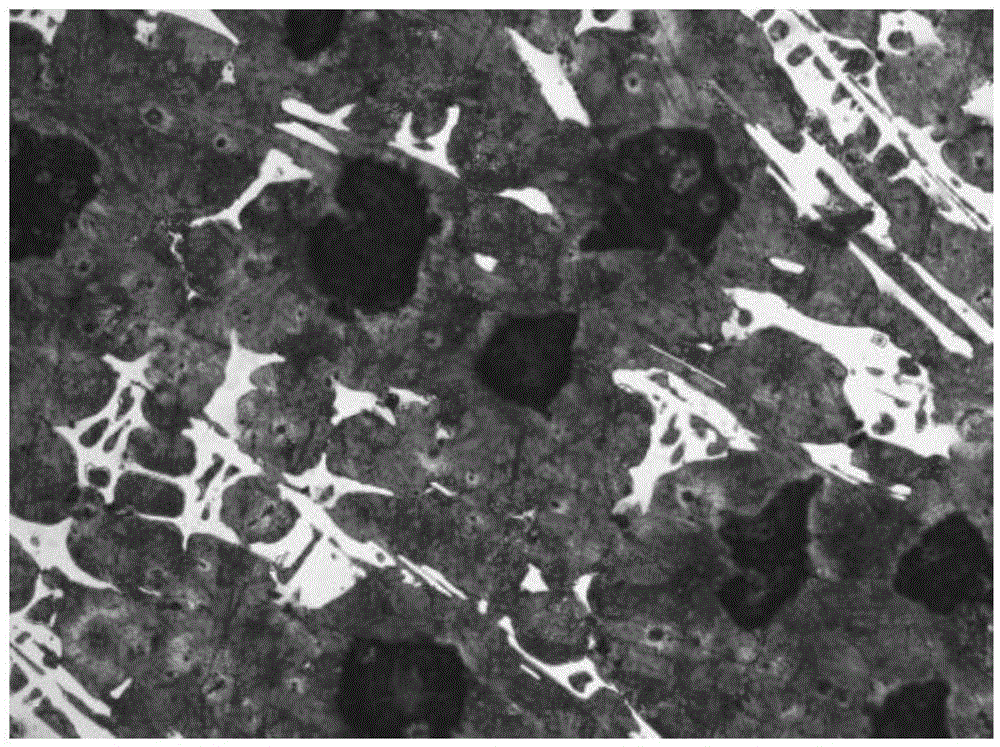

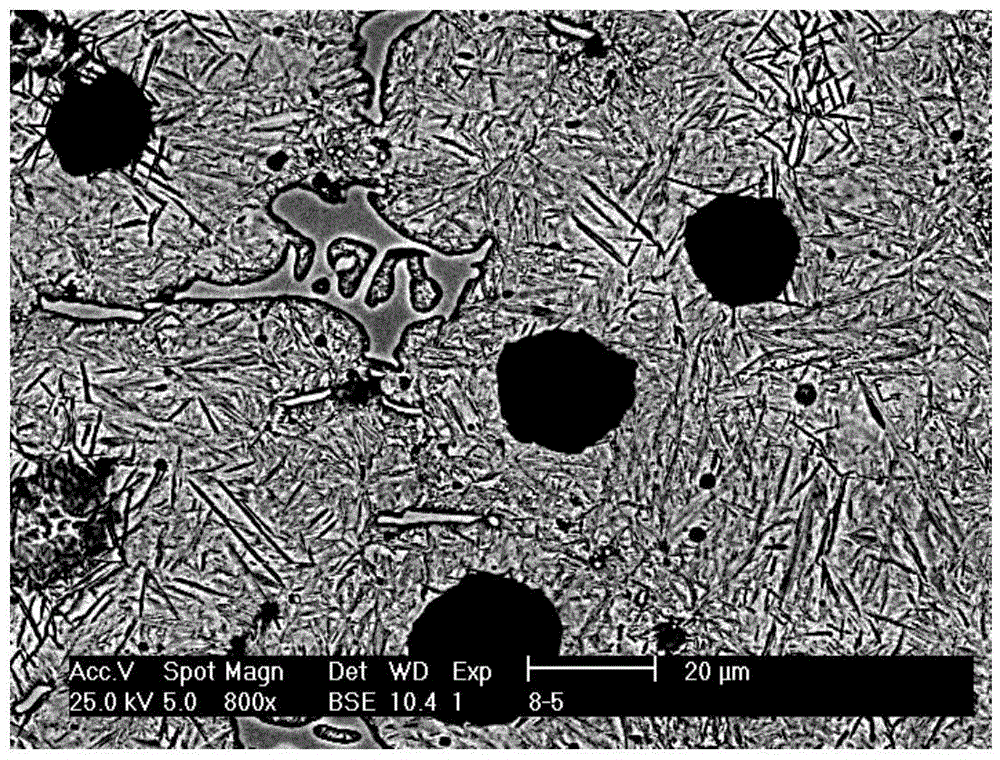

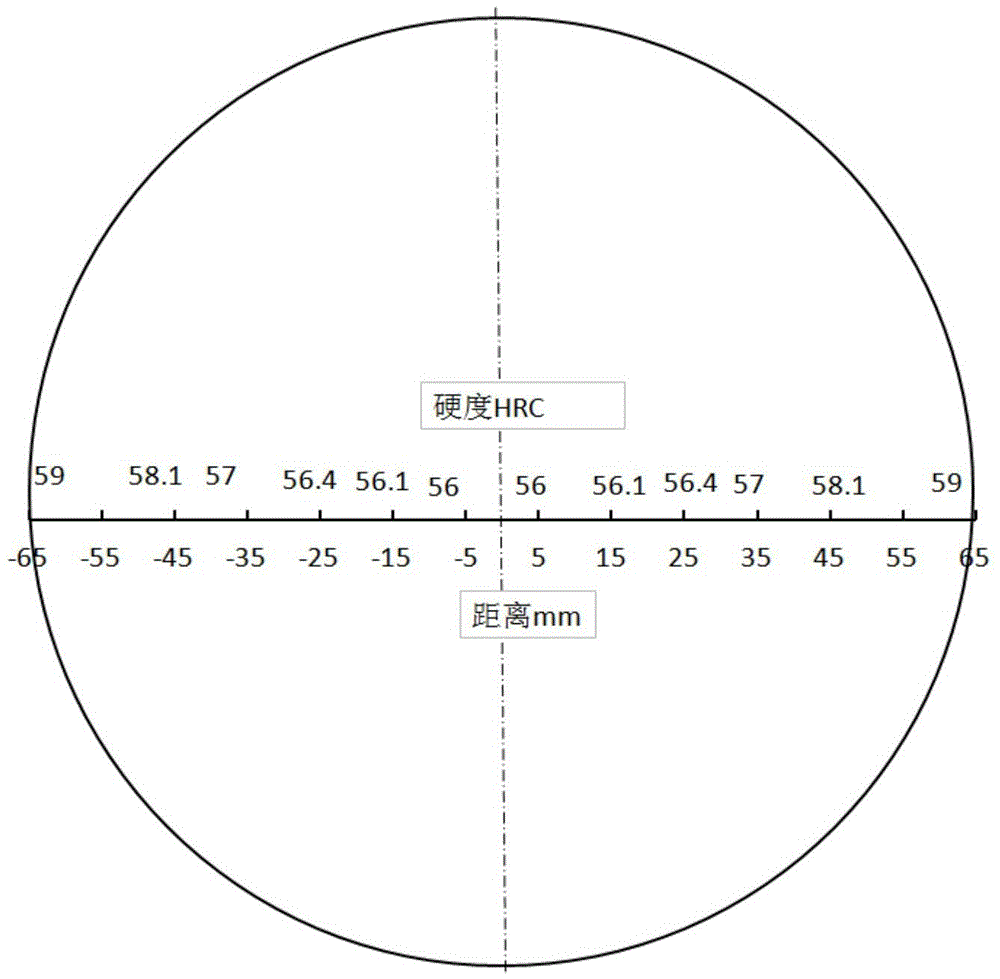

The invention discloses an Ausferrite ductile cast iron grinding ball, and relates to a spherulitic graphite-contained cast iron alloy. The Ausferrite ductile cast iron grinding ball comprises the following chemical elements in percentage by mass: 3.3-3.7% of C, 2.0-3.0% of Si, 1.0-2.5% of Mn, 0.7-3.0% of Cr, 0.1-1.0% of Mo, 0.1-1.0% of Cu, 0.04-0.08% of P, 0.01-0.020% of S, 0.03-0.05% of Mg, 0.02-0.04% of Ce, 0.03-0.07% of B, 0.06-0.12% of Ti, 0.03-0.2% of V, and the balance of Fe. The Ausferrite ductile cast iron grinding ball is prepared by the steps of preparation and smelting of raw materials, spheroidizing treatment, inoculation treatment and microalloying treatment, and isothermal quenching heat treatment. The Ausferrite ductile cast iron grinding ball overcomes the defects of low production efficiency and high consumption of electric energy of a ball mill due to easy surface stripping and crushing and shorter fatigue life of an existing grinding ball product in the service process.

Owner:HEBEI UNIV OF TECH

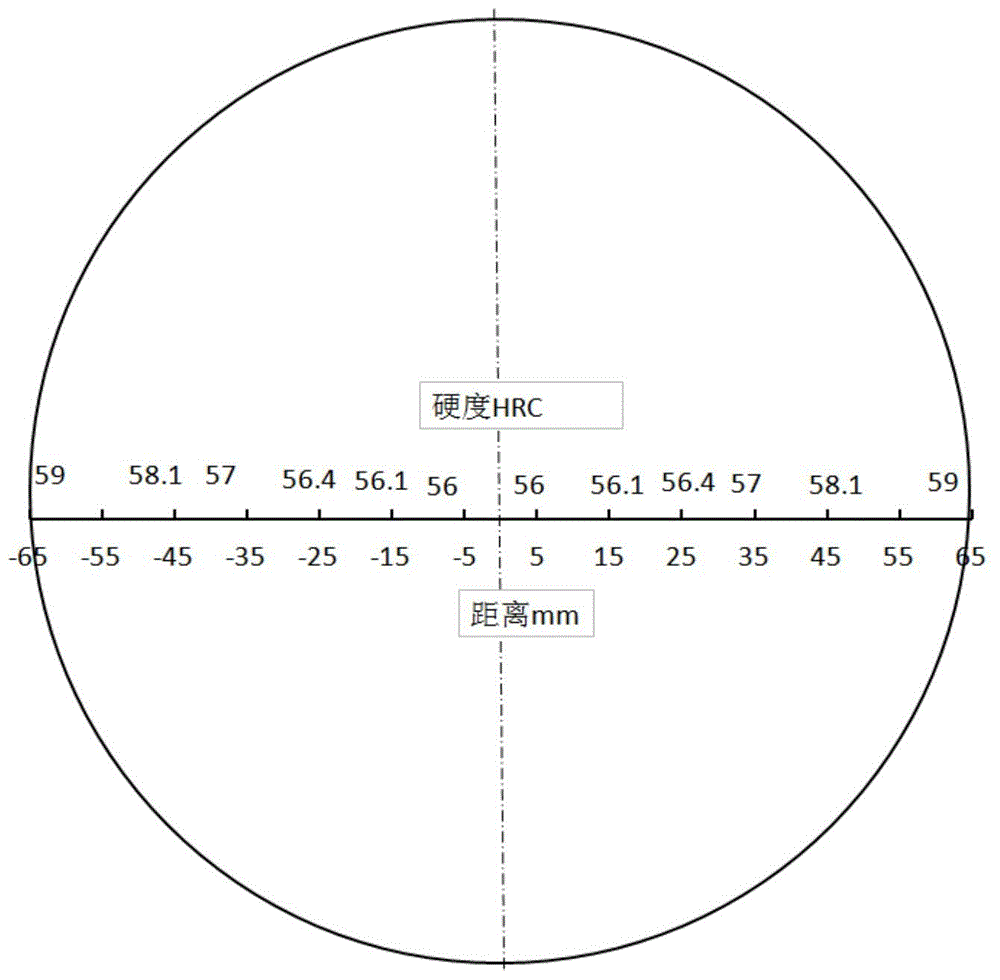

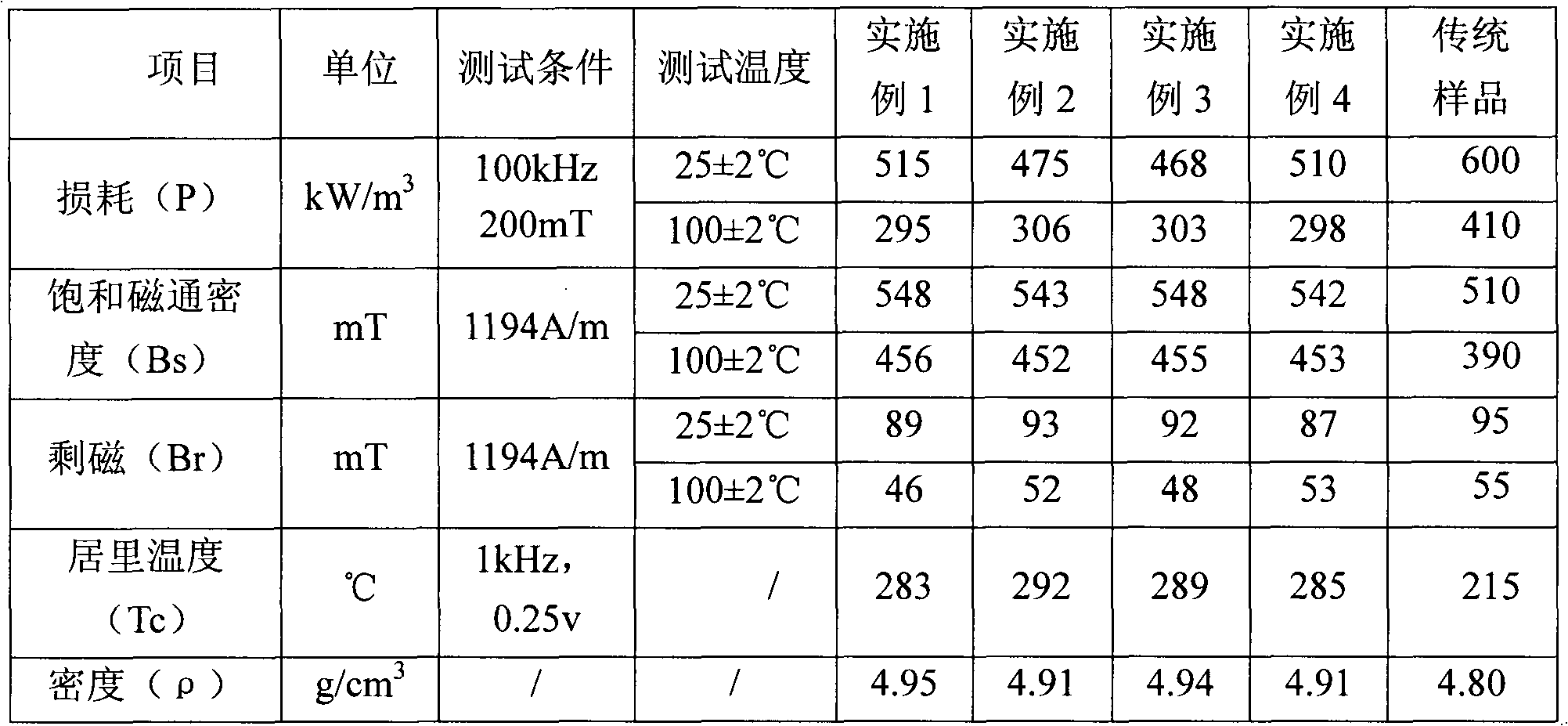

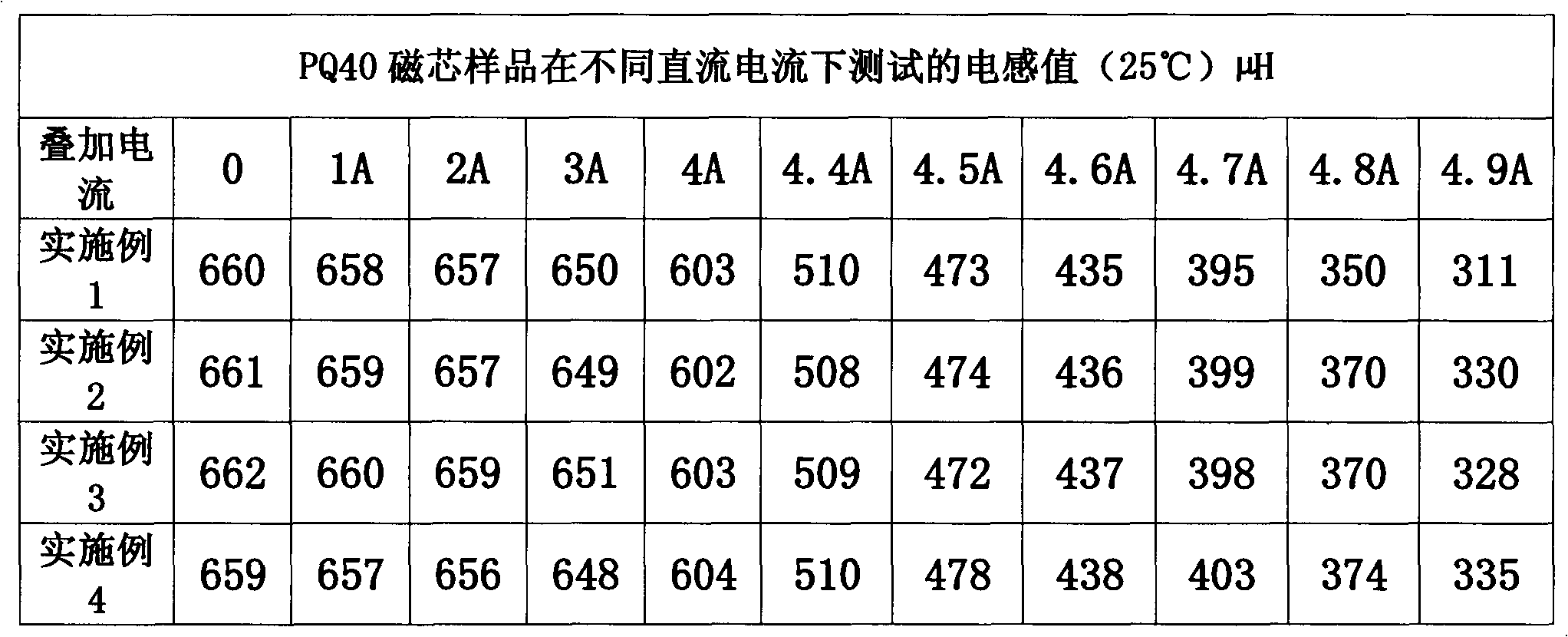

High-saturation magnetic flux, high-direct current superposition and low-loss soft magnetic material and preparation method thereof

The invention relates to a high-saturation magnetic flux, high-direct current superposition and low-loss soft magnetic material and a preparation method thereof. The soft magnetic material comprises the following main components: 53.5 to 55 molar percent of Fe2O3, 4 to 9.5 molar percent of ZnO, and the balance of MnO; and based on the total weight of the main components, the soft magnetic material comprises the following auxiliary components: 0.01 to 0.05 weight percent of WO3, 0.005 to 0.03 weight percent of NiO, and 0.02 to 0.06 weight percent of ZrO2. The soft magnetic material has higher saturation magnetic flux density Bs in a wide temperature range and a larger difference between the saturation magnetic flux density Bs of the soft magnetic material and residual magnetic flux density Br exists, power consumption is greatly reduced in the wide temperature range particularly, the superposition performance is high, and Curie temperature is relatively high, so that a plurality of electromagnetic parameters are matched more optimally, and the soft magnetic material is particularly suitable for realizing the higher and more stable electrical inductance function on various occasions with large direct current superposition.

Owner:RUYUAN DONGYANGGUANG MAGNETIC MATERIAL

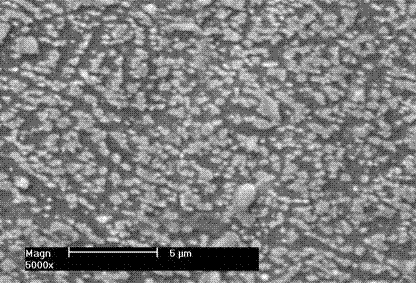

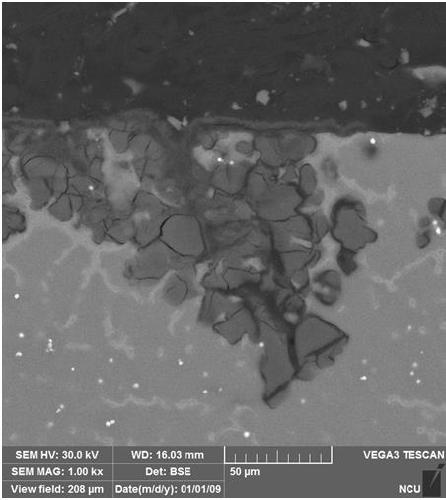

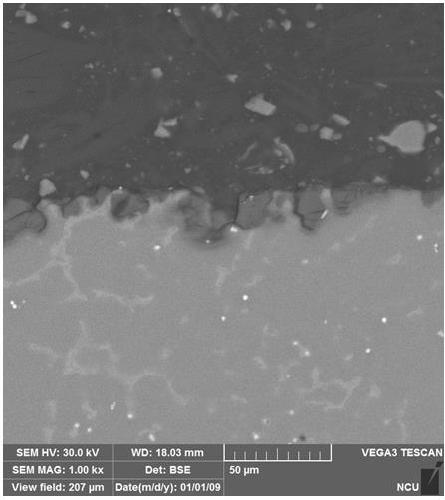

Method for micro-alloying treatment of ausferrite ductile cast iron grinding balls

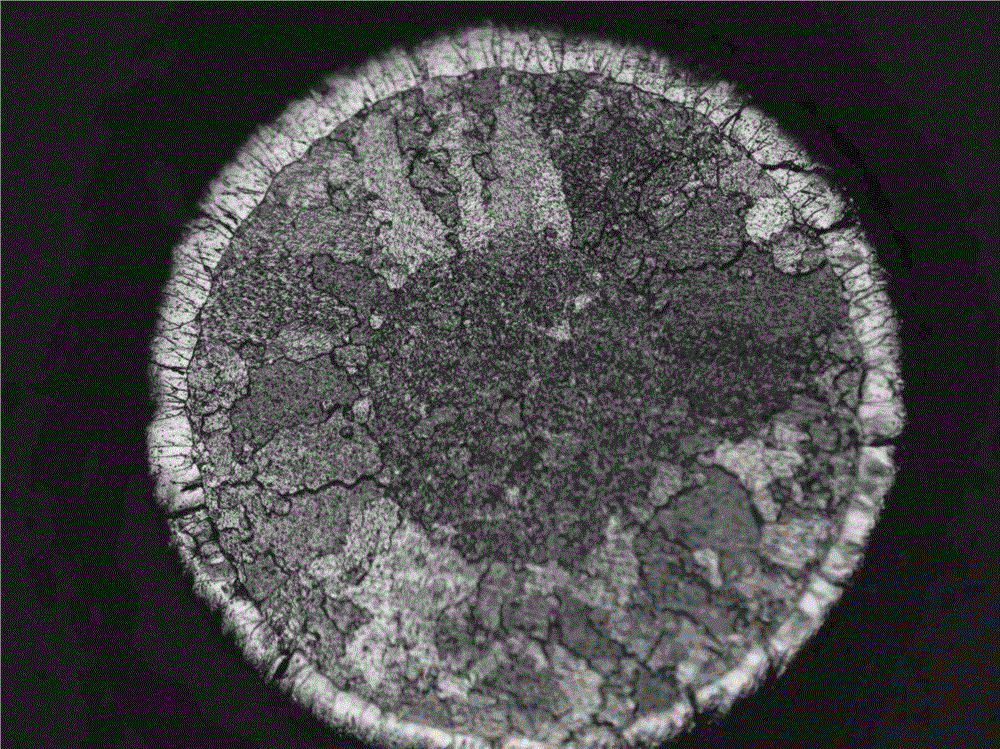

InactiveCN104831156AImprove absorption rateUniformly distributed refinementProcess efficiency improvementCarbideChemical element

The invention provides a method for micro-alloying treatment of ausferrite ductile cast iron grinding balls. The ausferrite ductile cast iron grinding balls comprise the following chemical element components in percentage by mass: 0.03-0.07% of B, 0.06-0.12% of Ti and 0.03-0.2% of V, which are respectively converted into the mass percents of BFe, TiFe and VFe alloys, wherein the alloys are weighed and then crushed into 0.5-1.0mm, and are added into a ladle together with a nodulizer and an inoculant; and during iron tapping, the heat and a stirring effect of high-temperature molten iron are utilized to ensure that BFe, TiFe and VFe alloy fine particles are dissolved in the molten iron and are absorbed by the molten iron, thereby finishing the micro-alloying treatment. By adopting the method for micro-alloying treatment of the ausferrite ductile cast iron grinding balls, provided by the invention, the absorptivity of B, Ti and V alloy elements is relatively high, so that graphite pebbles and carbides of the ausferrite ductile cast iron grinding balls are uniformly distributed and are refined, and mechanical properties are improved.

Owner:LIUZHOU JINDUN MACHINERY

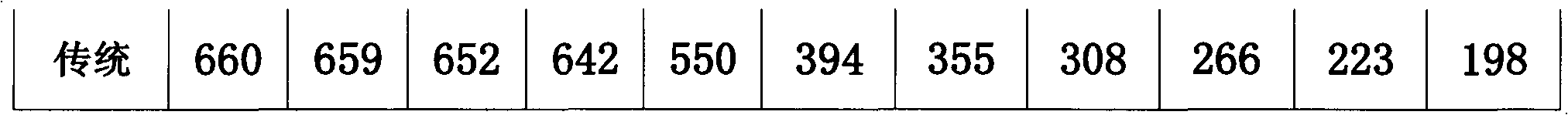

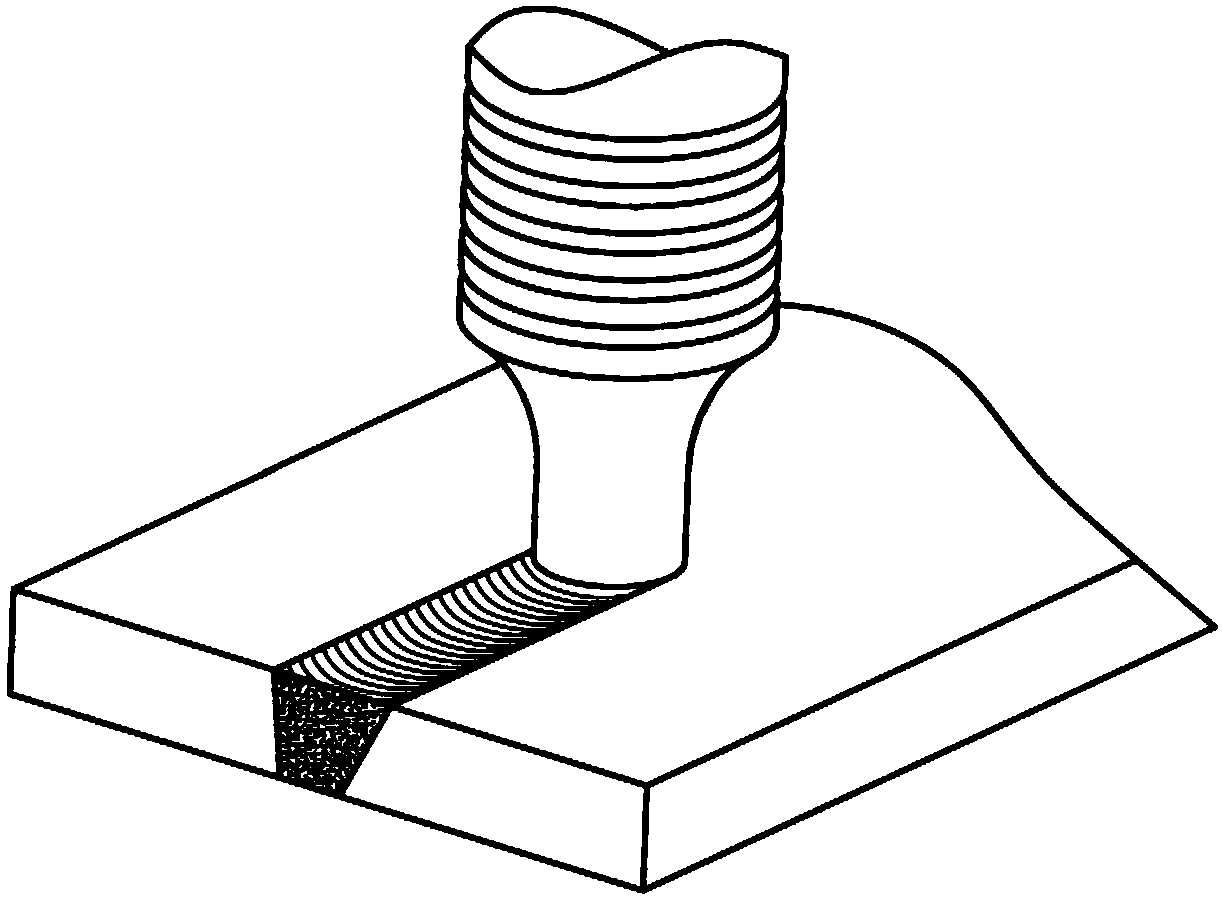

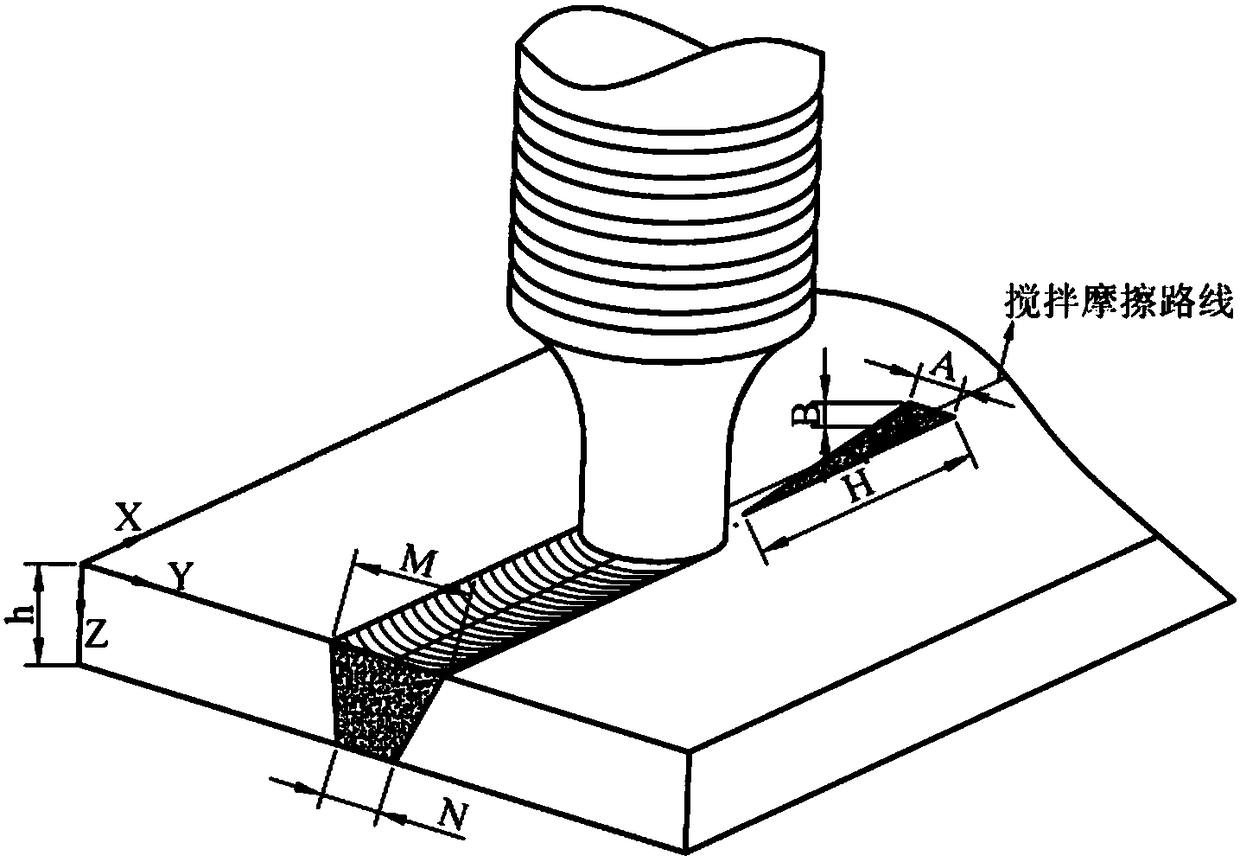

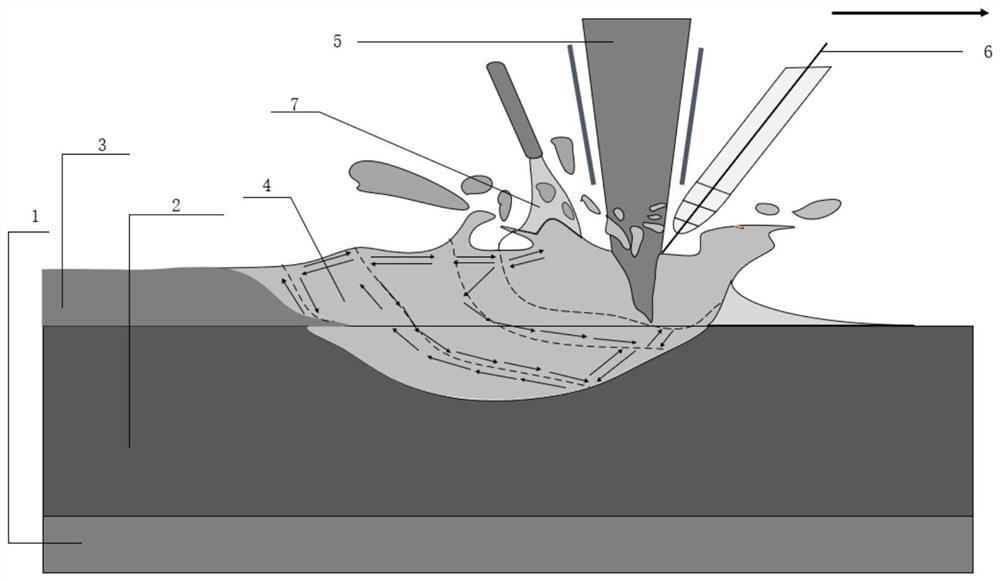

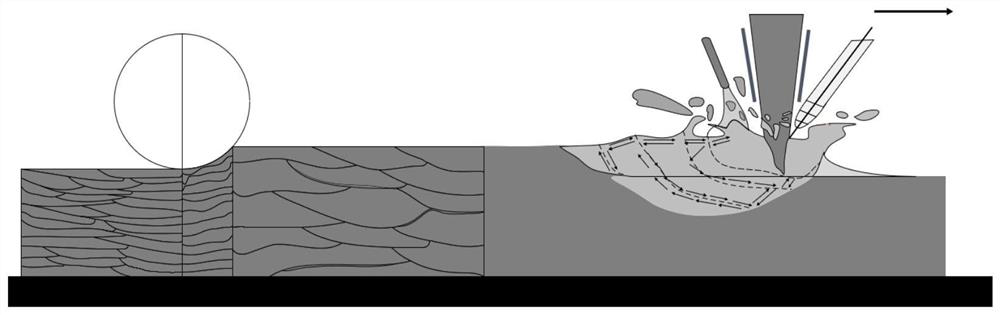

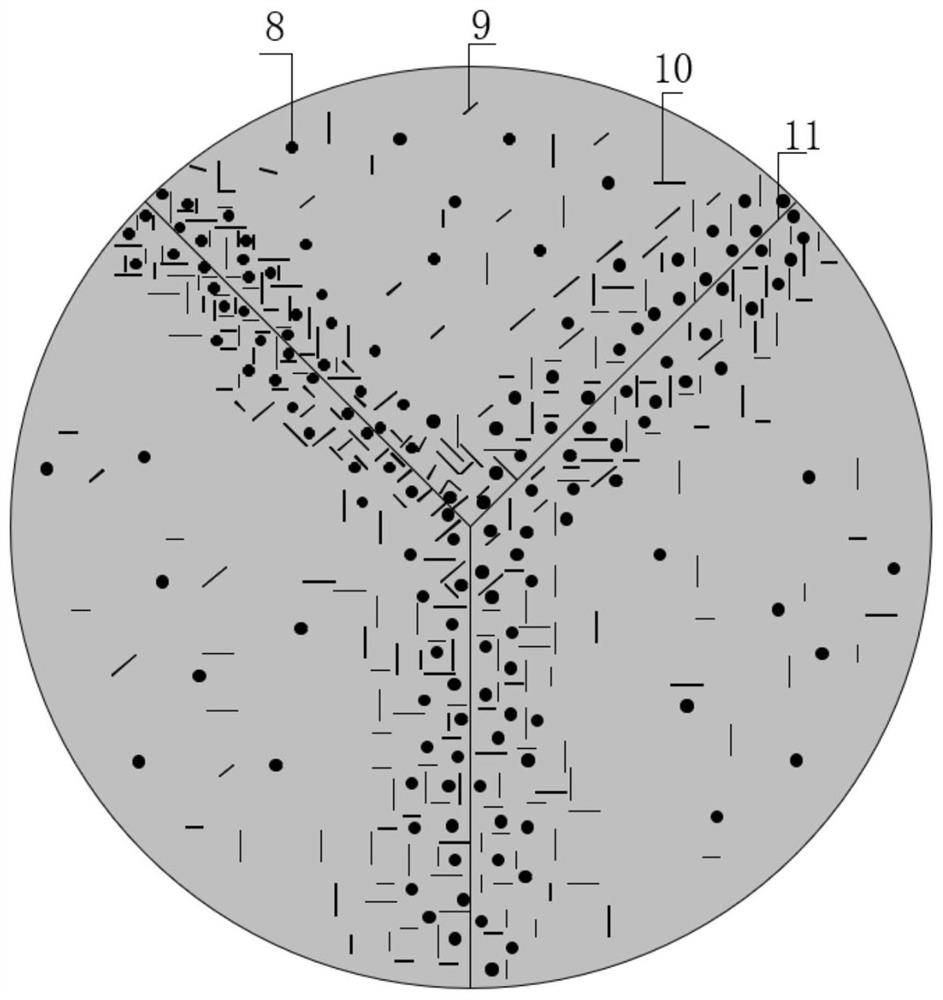

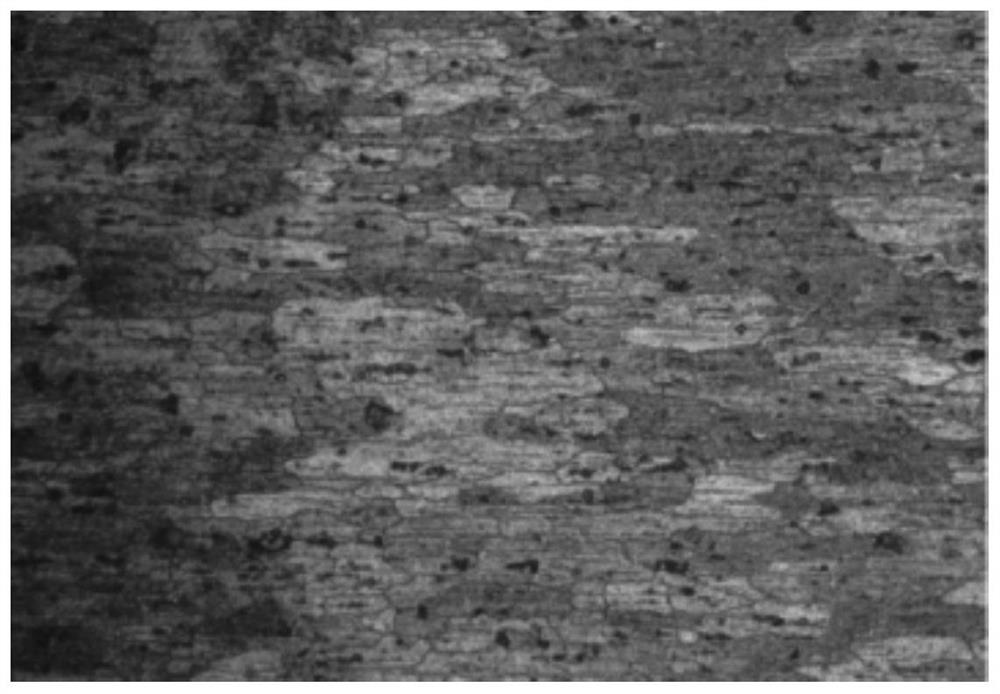

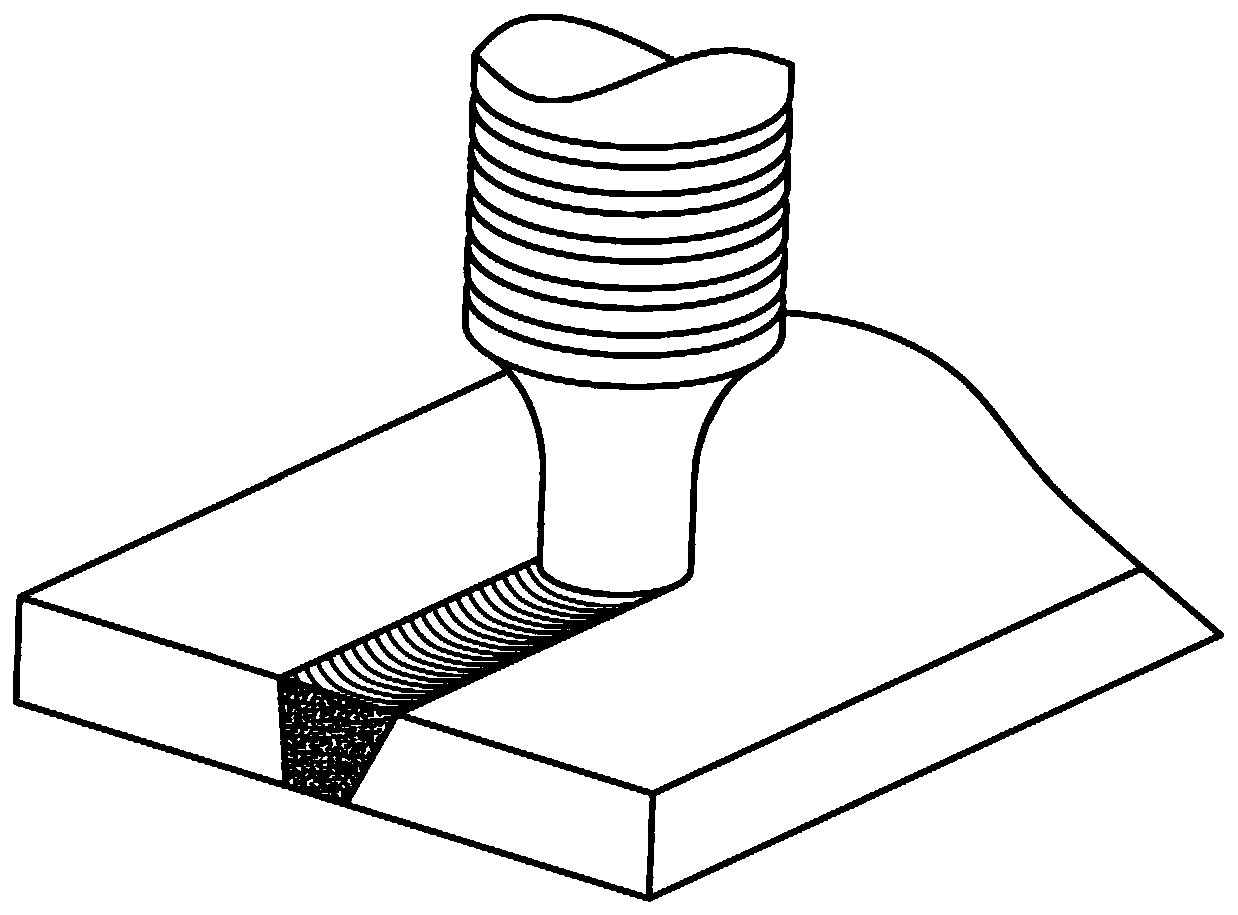

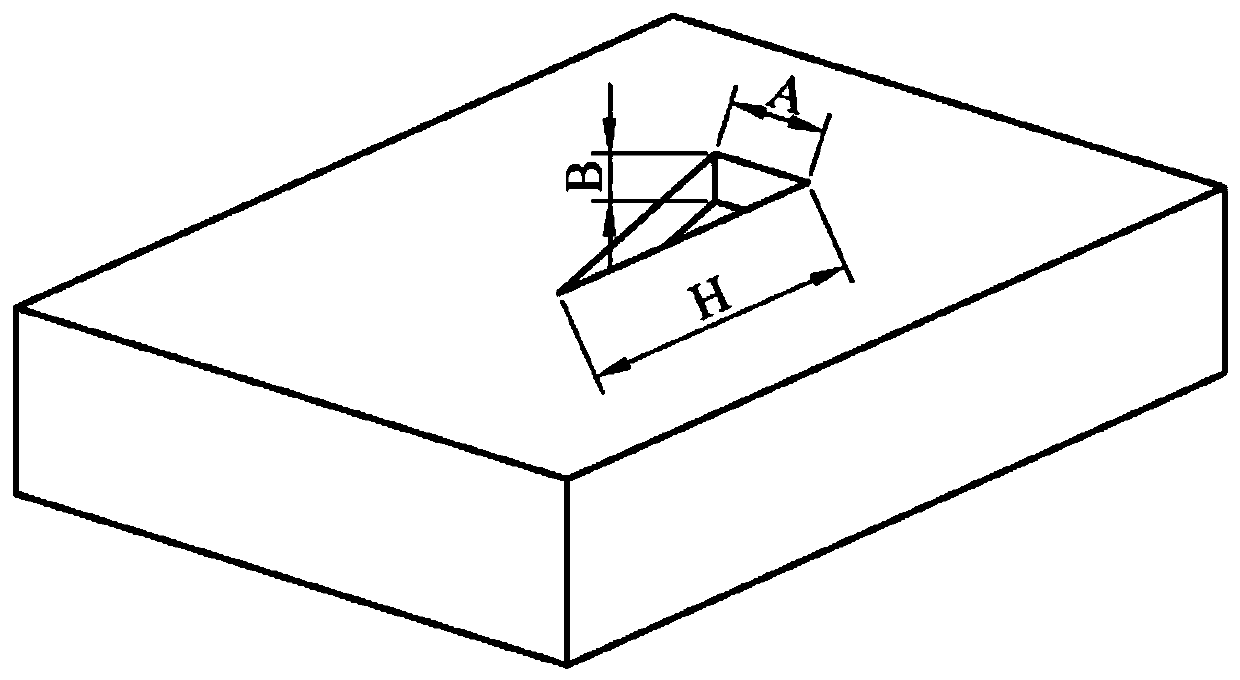

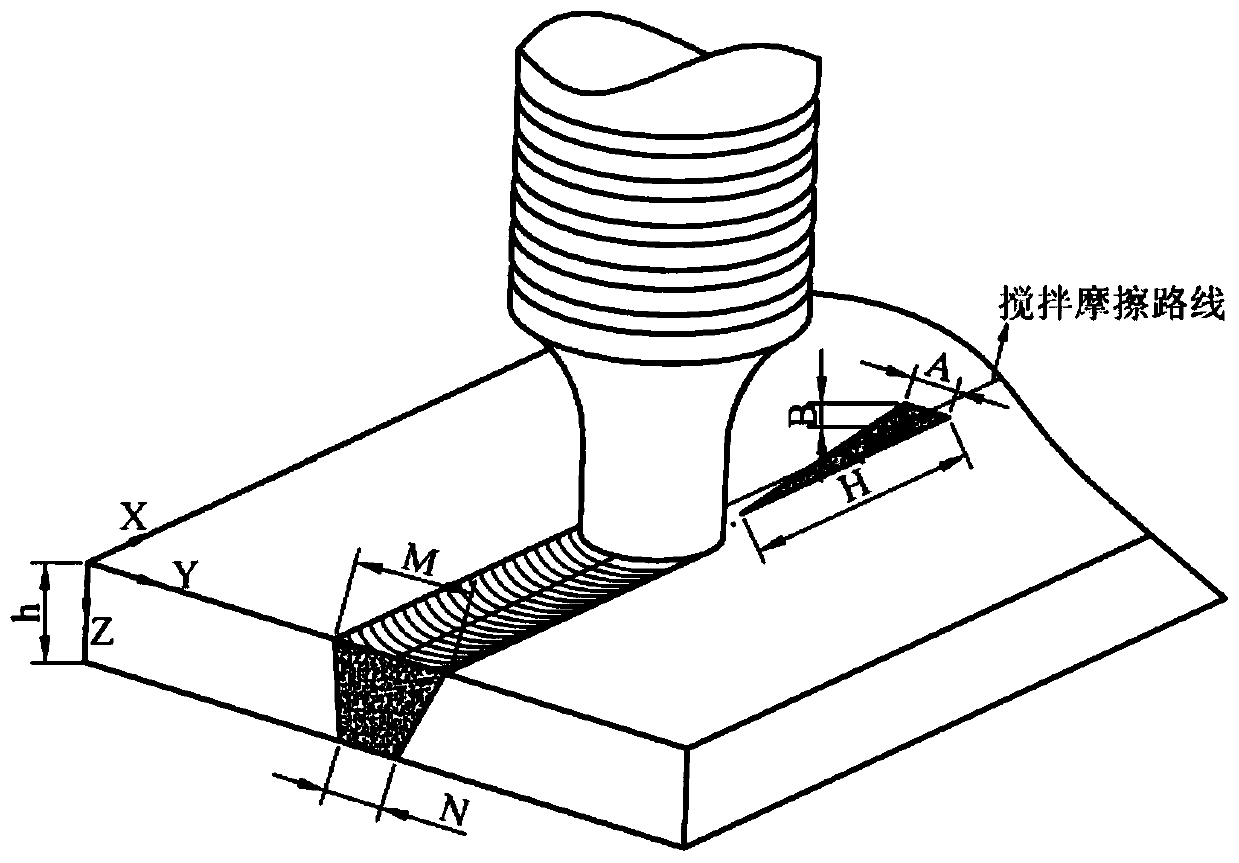

Preparation method of gradient functional material based on friction-stir welding

InactiveCN108608108AReduce manufacturing costAvoid crackingNon-electric welding apparatusMechanical propertyElectric field

The invention discloses a preparation method of a gradient functional material based on friction-stir welding. The preparation method comprises the following steps: adding a reinforced phase materialto a substrate by means of a right-angled triangular prism groove structural design on the substrate; and generating heat by mutual friction of a stirring head and a material in a substrate welding region, wherein the substrate welding region is softened plastically and the material in the substrate welding region drives the reinforced phase material to flow plastically under the action of the stirring head, so as to form a uniform gradient functional material from the material in the substrate welding region and the reinforced phase material. The method disclosed by the invention does not need special environments such as vacuum, temperature, electric field and magnetic field, and is low in preparation cost; by means of a solid state processing mode, formation of cracks, pores and oxidesin the material can be avoided effectively, and the gradient functional material which is high in compactness and uniform to mix can be obtained. Various types of gradient functional materials can beprocessed; the preparation method is a green processing technology, and the gradient functional material which is higher in mechanical property can be obtained.

Owner:JILIN UNIV

Semi-solid flow variable rheolytic pressure casting forming method for flame-retardant magnesium alloy

InactiveCN108315621AImprove mechanical propertiesImprove flame retardant performanceCombustionPressure casting

The invention provides a semi-solid flow variable rheolytic pressure casting forming method for a flame-retardant magnesium alloy. The alloy comprises the following components of , by mass, 6.5- 9.5 wt% of Al, 0.5-2.5 wt% of Zn, 0.5-2.5 wt% of Y, 0.2-2 wt% of Ca, 0.5-1.5 wt% of Ce and the balance Mg. The method comprises the following steps of preparation of flame-retardant magnesium alloy semi-solid slurry and semi-solid rheological pressure casting. According to the semi-solid flow variable rheolytic pressure casting forming method, three elements of Y, Ca and Ce are simultaneously added into Mg-Al-Zn, oxidation and combustion of the magnesium alloy can be further prevented, so that the strength and the heat treatment strengthening effect of the magnesium alloy are improved; filling andsolidification are carried out under a low-pressure high-speed condition through a pressure casting process, the semi-solid slurry flows in a laminar flow mode during the filling process, so that theoverall structure of the casting is compact, the surface quality is high, and the room temperature mechanical property of the obtained flame-retardant magnesium alloy is excellent.

Owner:SHANGHAI JIAO TONG UNIV

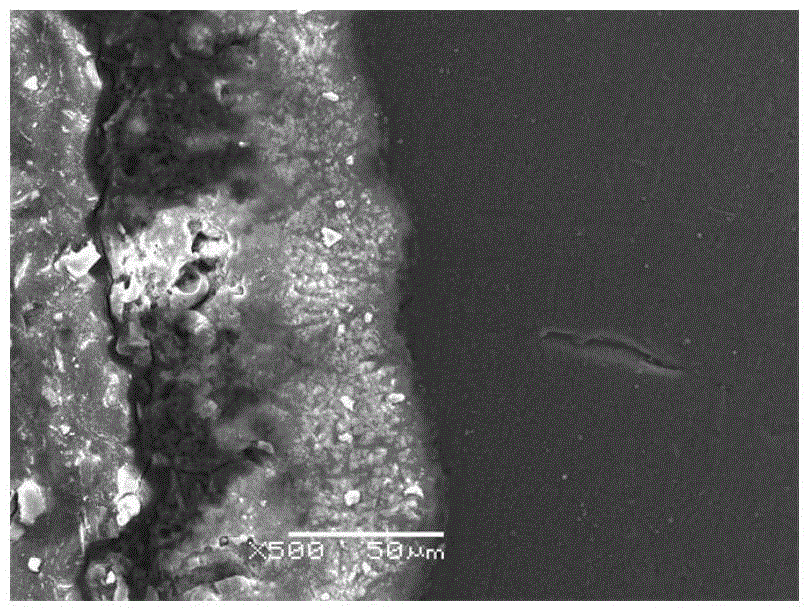

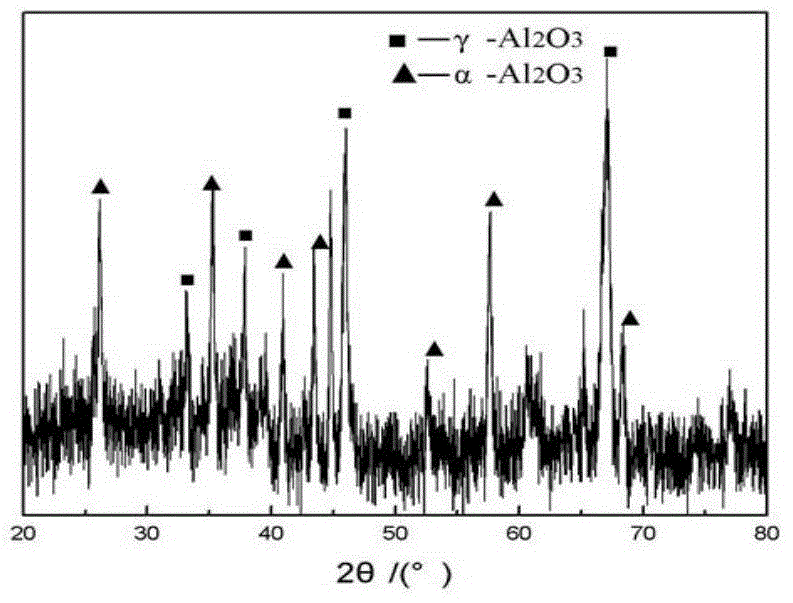

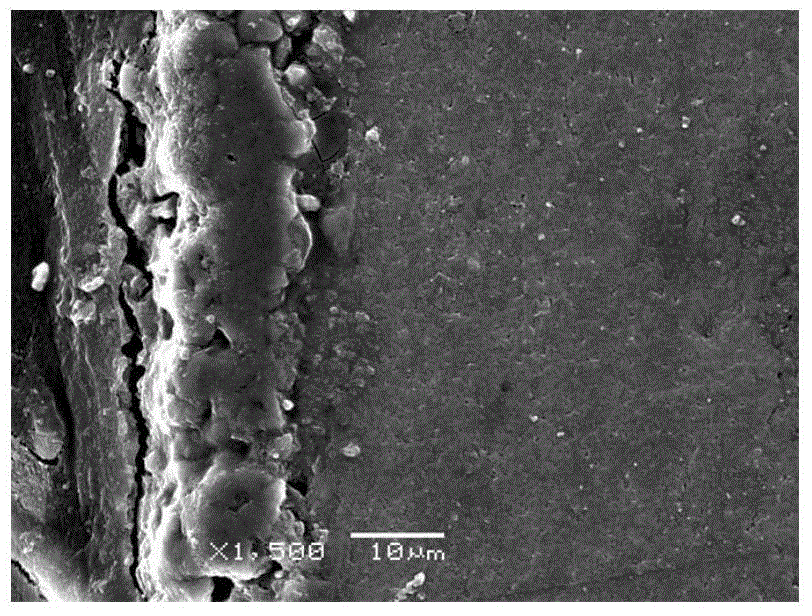

Micro-arc oxidation process method for pre-treating aluminum alloy based on solution and aging

PendingCN104947166AShape and Size OptimizationUniform and fine distribution of strengthening phaseAnodisationMicro arc oxidationSurface finishing

The invention relates to surface treatment of aluminum alloys, in particular to a wear-resisting and anti-corrosion surface treatment method used for an aluminum alloy component, specifically a micro-arc oxidation process method for pre-treating an aluminum alloy based on solution and aging. A micro-arc oxidation technology is adopted for the aluminum alloy component to prepare a wear-resisting and anti-corrosion ceramic layer on an aluminum alloy surface. The micro-arc oxidation process method comprises the following steps: carrying out solution treatment, carrying out ageing treatment, grinding, polishing and carrying out micro-arc oxidation treatment; and after carrying out the micro-arc oxidation treatment, obtaining the ceramic layer which is 80-90 [mu]m in thickness. The micro-arc oxidization ceramic layer prepared by the process method is relatively large in thickness and relatively short in preparation time; the process method has the characteristics of being simple and convenient in process, low in cost, green and environmentally-friendly, high in ceramic layer binding force, suitable for mass production and the like, and can improve the wear resistance and the corrosion resistance of the aluminum alloy surface.

Owner:NANJING INST OF TECH

Preparation method of ultrasonic Mg-Al-Zn-Mn-Nd corrosion resistant rare earth magnesium alloy

A preparation method of an ultrasonic Mg-Al-Zn-Mn-Nd corrosion resistant rare earth magnesium alloy comprises the steps: putting a Mg-Al-Zn-Mn series alloy into a crucible with the furnace temperatureof 730-750 DEG C, heating and melting, adding small block Mg-20% Nd intermediate alloy wrapped by aluminum-foil paper, and carrying out heat preservation until the alloy is melted completely; then extending an ultrasonic amplitude-change pole into the alloy melt, and carrying out intermittent ultrasonic treatment, wherein the intensity is 1000-2000 W, the intermittent ultrasonic treatment is performed for 15-20 s each time and is performed every other 15-20 s, and the total time is 700-900 s; and finally, rapidly pouring into a preheated metal die, wherein the obtained alloy comprises the components by the weight percentage: 7.0-9.1% of aluminum, 1.2-1.5% of zinc, 0.7-0.9% of manganese, 0.5-1.5% of neodymium, and the balance magnesium. A second phase structure of the alloy is more uniformin distribution, a cathode phase with low self-corrosion potential is formed by addition of rare earth elements, and the whole corrosion performance of the alloy is greatly improved.

Owner:镁高镁诺奖(铜川)新材料有限公司

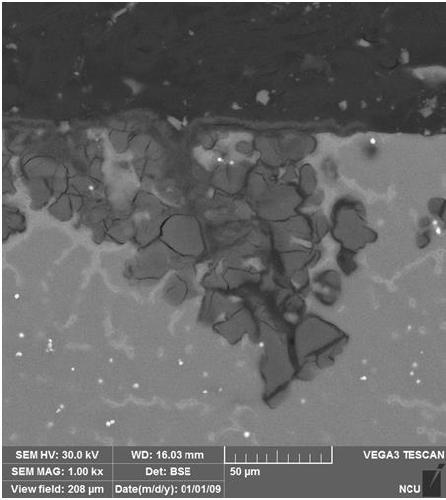

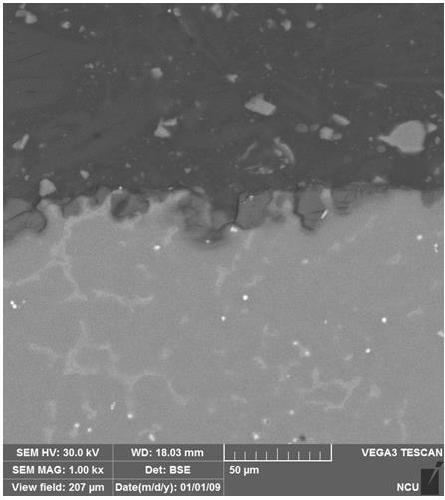

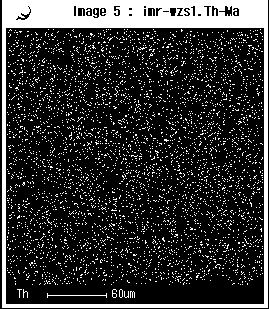

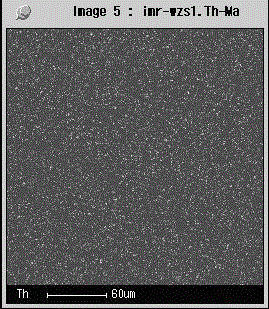

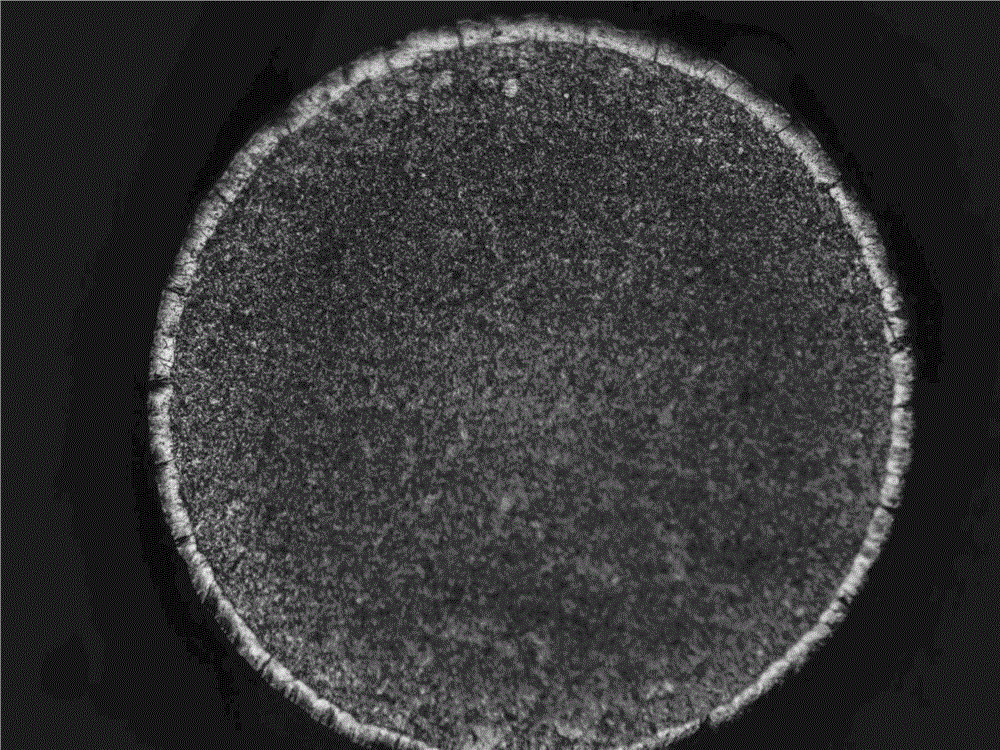

Thorium tungsten wire used for winding microwave oven magnetron and manufacturing method of thorium tungsten wire

ActiveCN103346054AIncrease in crystal defectsSuppress coarseningTransit-tube cathodesCold cathode manufactureMicrowave ovenThorium oxide

The invention belongs to the technical field of metal material manufacturing, and particularly relates to a thorium tungsten wire used for winding a microwave oven magnetron and a manufacturing method of the thorium tungsten wire. The thorium tungsten wire is characterized by comprising 0.5-1.5% of thorium oxide, 0.0020-0.0080% of potassium and 97-98% of tungsten. Compared with the prior art, the thorium tungsten wire and the manufacturing method have the advantages that (1) according to the thorium tungsten wire, though 0.0020-0.0080% of the potassium is added, thorium oxide particles are still fine and uniform; (2) the thorium tungsten wire contains microelement potassium in content, after coils of the microwave oven magnetron wound through the thorium tungsten wire are carbonized at a high temperature, crystal grains cannot grow larger easily, organization stability is maintained, and the situation that the microwave oven magnetron cannot break due to shaking in the packaging and delivery transportation processes after being produced is guaranteed.

Owner:威海多晶钨钼科技有限公司

Stainless steel seamless tube and preparation method and application thereof

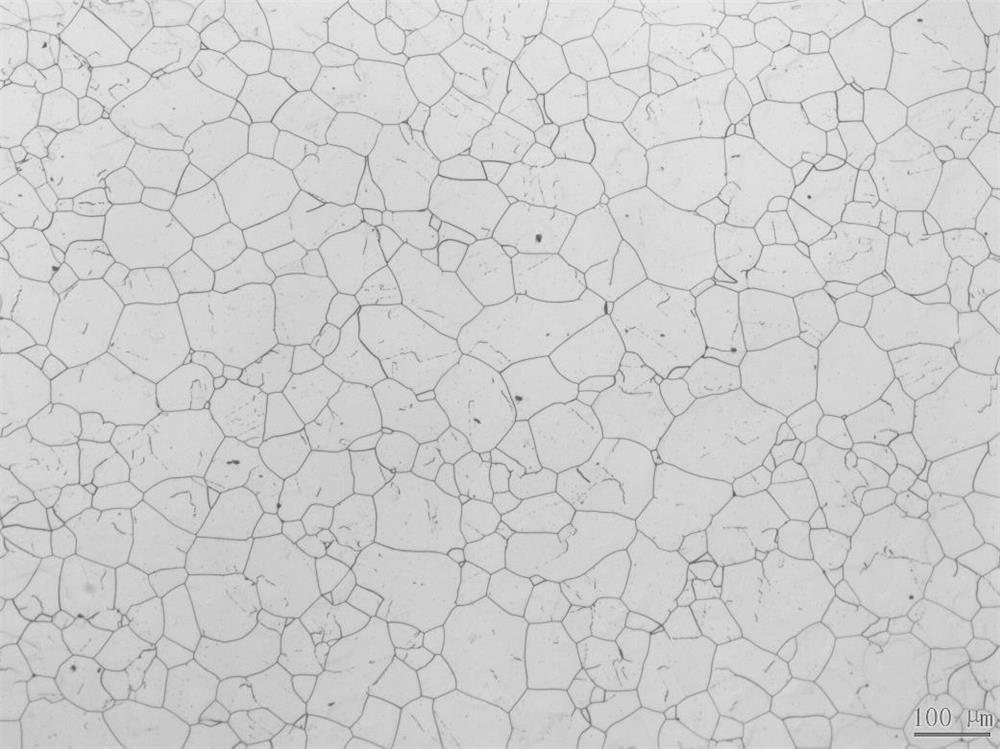

The invention relates to the field of seamless steel pipes, in particular to a stainless steel seamless pipe and a preparation method and application thereof.The preparation method comprises the following steps that cold drawing is conducted on a pipe in a small-deformation mode, a medium-deformation mode and a large-deformation mode respectively, and solid solution heat treatment needs to be conducted on the pipe after cold drawing is finished every time; and finally, the stainless steel seamless tube with the uniform internal grain structure size is obtained. According to the method, the grain structure in the stainless steel seamless tube is refined and uniformly distributed in a mode of combining different deformation amounts with heat treatment, and finally, a uniform structure with the grain size of 4-6 levels and the level difference smaller than 2 levels is achieved. Meanwhile, by adopting the manufacturing process, the large-diameter stainless steel seamless steel which is uniform in grain structure distribution, larger than 800mm in pipe outer diameter and larger than 10mm in wall thickness can be manufactured, and the large-diameter stainless steel seamless steel pipe can be used for a main pipeline system of an advanced nuclear power station.

Owner:ZHEJIANG JIULI HI TECH METALS

Semi-high speed steel copper soldering inlaid steel cutting blade and manufacturing method thereof

ActiveCN102776446BImprove sharpnessImprove impact toughnessFurnace typesMetal working apparatusTemperingSoldering

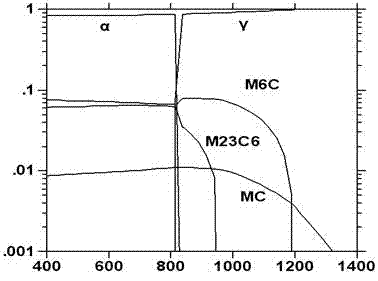

The invention discloses a semi-high speed steel copper soldering inlaid steel cutting blade and a manufacturing method thereof, which belong to the field of mechanical blades. The cutting blade is manufactured by welding a semi-high speed shear steel on a cutter body through copper soldering, wherein the semi-high speed shear steel comprises the following chemical elements by weight percent: 0.56-0.65% of C, 0.40-0.60% of Si, 0.25-0.40% of Mn, 6.0-6.8% of Cr, 1.6-2.5% of W, 4.2-5.2% of Mo, 0.7-0.9% of V, 0.1-0.2% of Nb, 0.3-0.4% of one of Co or Ni, no more than 0.02% of S, no more than 0.025% of P and the balance of Fe. The method for preparing comprises: smelting the semi-high speed shear steel, carrying out forging rolling at 870 DEG C-1080 DEG C, and then annealing; secondarily, heating to 1160 DEG C-1180 DEG C, carrying out copper soldering to inlay steel, and quenching at the same time; and finally, tempering. The cutting blade has the same hardness as the original high speed steel copper soldering inlaid steel cutting blade, but has higher sharpness, and is easy for cutter sharpening, and the material cost and the technological cost are lowered.

Owner:ANHUI JIALONG KNIVES MFG

Preparation method for semi-high speed steel

The invention discloses a preparation method for semi-high speed steel. The method includes the steps of (1) smelting, (2) forging and rolling, (3) annealing, (4) simultaneous copper brazing and quenching, and (5) tempering. In the step of smelting, smelting is conducted through an electric induction furnace, or electroslag remelting is conducted after smelting through the electric induction furnace; the semi-high speed shear steel is composed of, by weight percentage, 0.56%-0.65% of C, 0.40%-0.60% of Si, 0.25%-0.40% of Mn, 6.0%-6.8% of Cr, 1.6%-2.5% of W, 4.2%-5.2% of Mo, 0.7%-0.9% of V, 0.1%-0.2% of Nb, 0.3%-0.4% of Co or Ni, 0-0.02% of S, 0-0.025% of P, and the balance Fe. The hardness of a paper cutting blade made of the semi-high speed steel is identical with that of an original paper cutting blade which is manufactured through copper brazing and high-speed steel inlaying, but the sharpness is higher, blade sharpening is easy, and material cost and process cost are reduced.

Owner:CHONGQING CHUNGU MACHINERY MFG CO LTD

Precision forging forming process of torque elastomer for 330 MPa-grade motor torque sensor

InactiveCN112359180AUniformly distributed refinementExtended service lifeElastomerElectric machinery

The invention discloses a precision forging forming process of a torque elastomer for a 330 MPa-grade motor torque sensor. A steel material is subjected to four times of spheroidizing annealing, watercooling and oil cooling are combined, refining and uniform distribution of steel material grains are facilitated, meanwhile, the heating and cooling speed in heat treatment is controlled, the problems of fine surface layer grains and a thick middle structure of a finished product of a torque elastomer precision forging are solved, the surface layer grains are refined, lattice distortion and dislocation density are reduced, the high-temperature friction, wear resistance, hardness and surface strength of the finished product of the precision forging are greatly improved, the wear rate is greatly reduced, and the service life of the torque elastomer is effectively prolonged.

Owner:盐城市明佳机械有限公司

Preparation method of Mg-Al-Zn-Mn-Gd corrosion resistant rare earth magnesium alloy

ActiveCN109112376AAccelerated corrosionUniformly distributed refinementRare-earth elementCorrosion resistant

The invention relates to a preparation method of an Mg-Al-Zn-Mn-Gd corrosion resistant rare earth magnesium alloy. The method comprises the following steps of putting an alloy of Mg-Al-Zn-Mn series into a crucible with a furnace temperature of 760-780 DEG C, heating until melting, adding a small block-shaped Mg-20% Gd intermediate alloy wrapped witth aluminum-foil paper, and preserving heat for 10-15 minutes until the alloy is completely melted; then stretching an ultrasonic amplitude transformer into above alloy melt to perform intermittent ultrasonic treatment at the intensity of 2,000-3,000w for 5-10 seconds each time every other 5-10 seconds, wherein time amounts to 300-500 seconds; finally pouring the alloy melt in a preheated metal mold to obtain the Mg-Al-Zn-Mn-Gd corrosion resistant rare earth magnesium alloy. The fine second-phase tissue of the alloy provided by the invention is more uniformly distributed, and meanwhile, the addition of rare earth elements forms a cathode phase of which the self corrosion potential is low, so that all the properties of the alloy are remarkably improved.

Owner:镁高镁诺奖(铜川)新材料有限公司

Semi-high-speed steel

The invention discloses a semi-high-speed steel. The semi-high-speed steel is prepared from the following chemical elements in percentage by weight: 0.58-0.62% of C, 0.48-0.52% of Si, 0.28-0.38% of Mn, 6.12-6.60% of Cr, 1.82-2.28% of W, 4.45-4.94% of Mo, 0.76-0.81% of V, 0.13-0.16% of Nb, 0.32-0.38% of Co or Ni, S which is less than or equal to 0.02%, P which is less than or equal to 0.025%, and the balance being Fe. According to the semi-high-speed steel disclosed by the invention, the hardness of a paper cutting blade made from the semi-high-speed steel is the same as that of an original copper-brazed steel-inlaid paper cutting blade made from high-speed steel, but the sharp degree of the paper cutting blade made from the semi-high-speed steel is higher, the paper cutting blade made from the semi-high-speed steel is easy to sharpen, and the material cost and the technology cost are reduced.

Owner:CHONGQING GUIKUN MACHINERY CO LTD

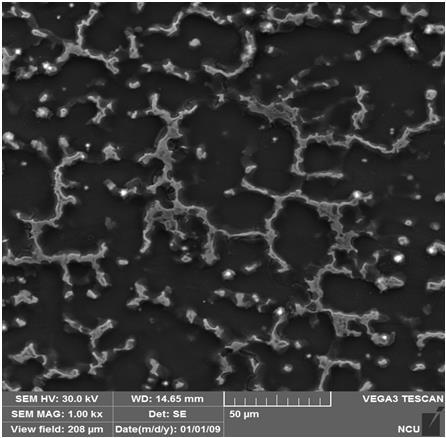

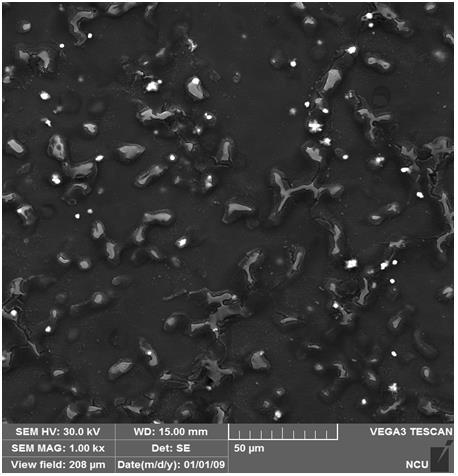

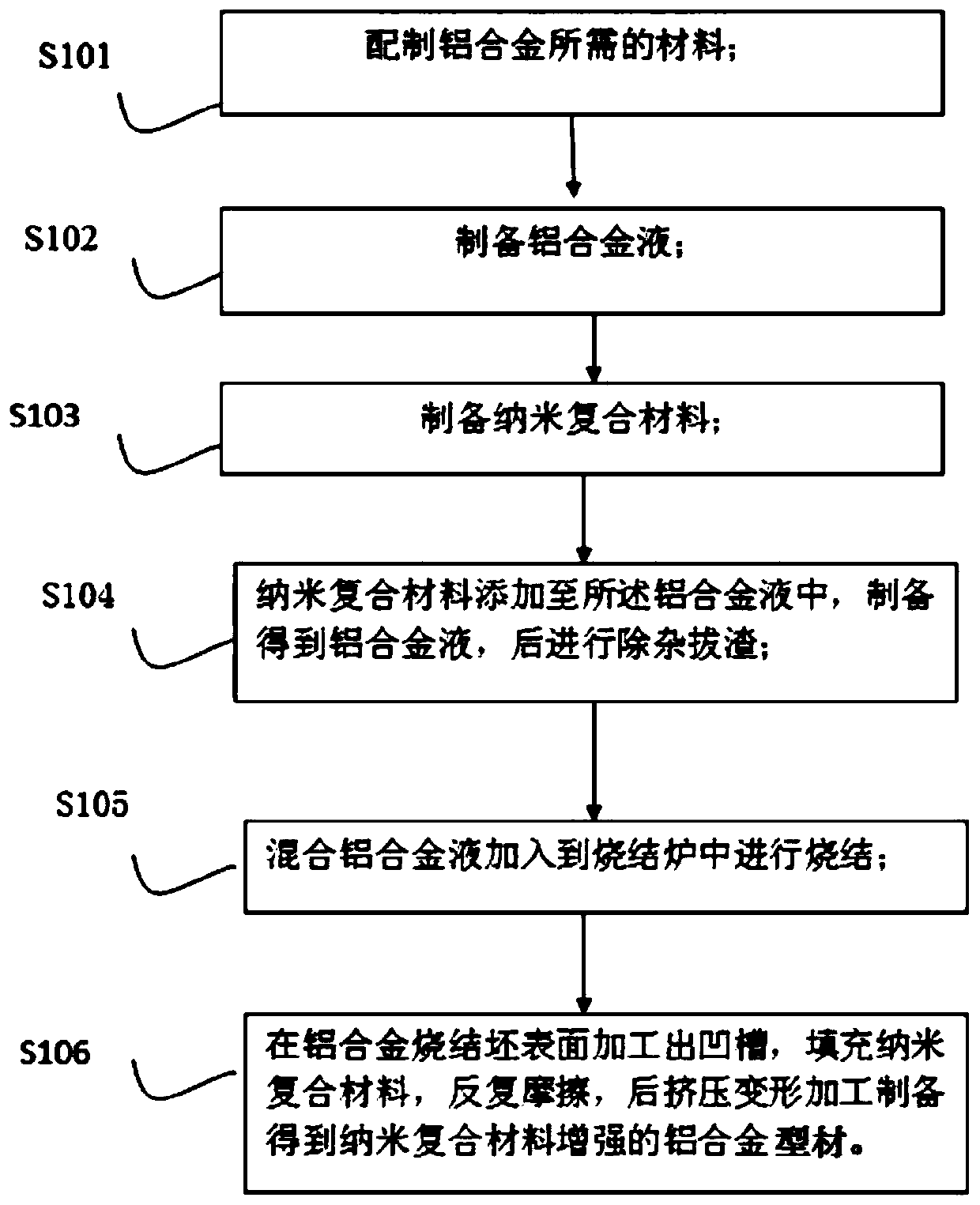

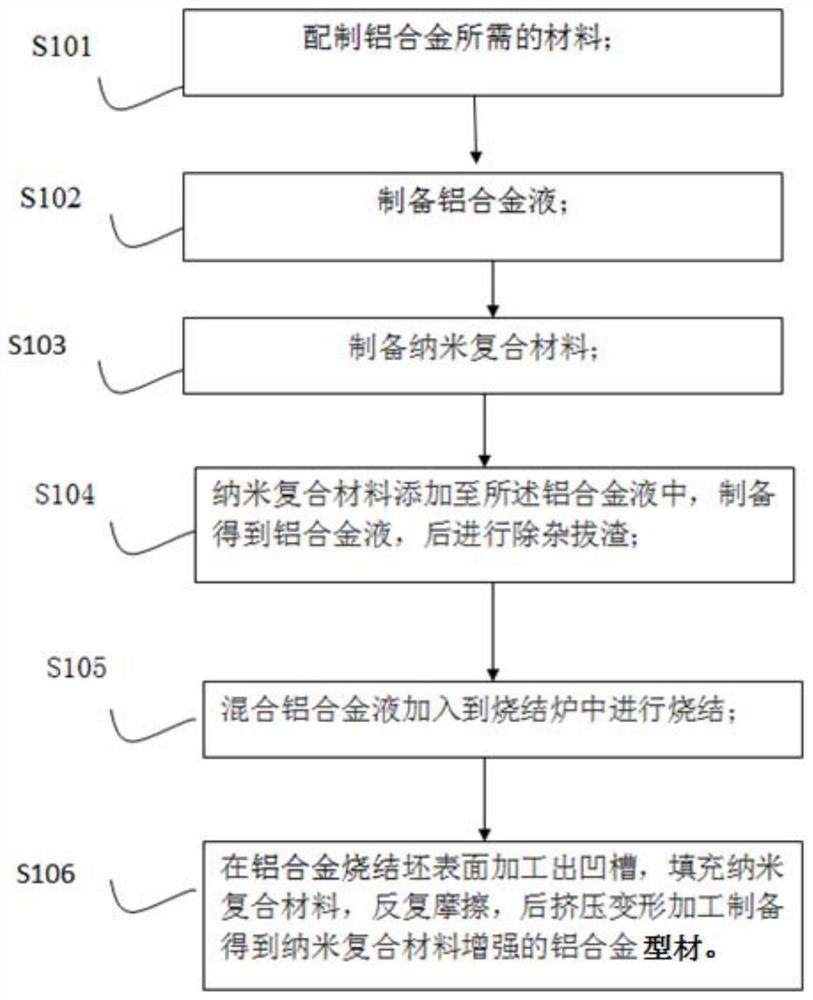

Method for reinforcing aluminum alloy profile through nano composite material

The invention provides a method for reinforcing an aluminum alloy profile through a nano composite material. Al2O3 and carbon nanotubes in a specific proportion are dispersed under the assistance of microwave ball milling; after the nano composite material is formed, 1 / 2 of the nano composite material is mixed with aluminum alloy liquid, the dispersity among components and the uniformity of particle mixing are improved advantageously, and the specific surface area of mixing and the surface interaction force of mixing can be effectively increased. Finally, the remaining 1 / 2 of the nano composite material is added in a filling mode after aluminum alloy is sintered, the combination degree of the nano composite material and the aluminum alloy is reinforced through repeated heating and friction, refining and uniform distribution of crystal grains are further promoted, the crystal boundary stability is improved synergistically, the high strength and plasticity of the aluminum alloy are ensured, and the wear resistance of the aluminum alloy can further be improved significantly. The method for reinforcing the aluminum alloy profile through the nano composite material solves the internal defects of the nano composite material in the aluminum alloy on the whole, and solves the problem of coarse crystal grains of the aluminum alloy.

Owner:佛山市三水凤铝铝业有限公司 +1

Microparticle enhanced special high temperature wear-resisting brazing bar and manufacturing method thereof

InactiveCN109702370AHigh tensile strengthImprove wear resistanceWelding/cutting media/materialsSoldering mediaMicrometerMicroparticle

The invention provides a microparticle enhanced special high temperature wear-resisting brazing bar. The brazing bar comprises a microparticle enhanced hollow copper brazing filler metal inner core, Co-coated Cr2O3 composite particles filled into the microparticle enhanced hollow copper brazing filler metal inner core, and a copper brazing flux coating adhering to the outer surface of the microparticle enhanced hollow copper brazing filler metal inner core. The microparticle enhanced hollow copper brazing filler metal inner core comprises a metal phase and micrometer SiC particles. The metal phase is composed of metal elements including, by mass percent, 1.1-1.4% of Ag, 0.6-0.9% of Mn, 0.4-0.5% of La, 1.3-2.93% of Sn, 1.6-1.8% of Nd and the balance Cu. The invention further provides a method for manufacturing the microparticle enhanced special high temperature wear-resisting brazing bar. The microparticle enhanced special high temperature wear-resisting brazing bar can improve wear-resisting performance and tensile strength of the brazing layer.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

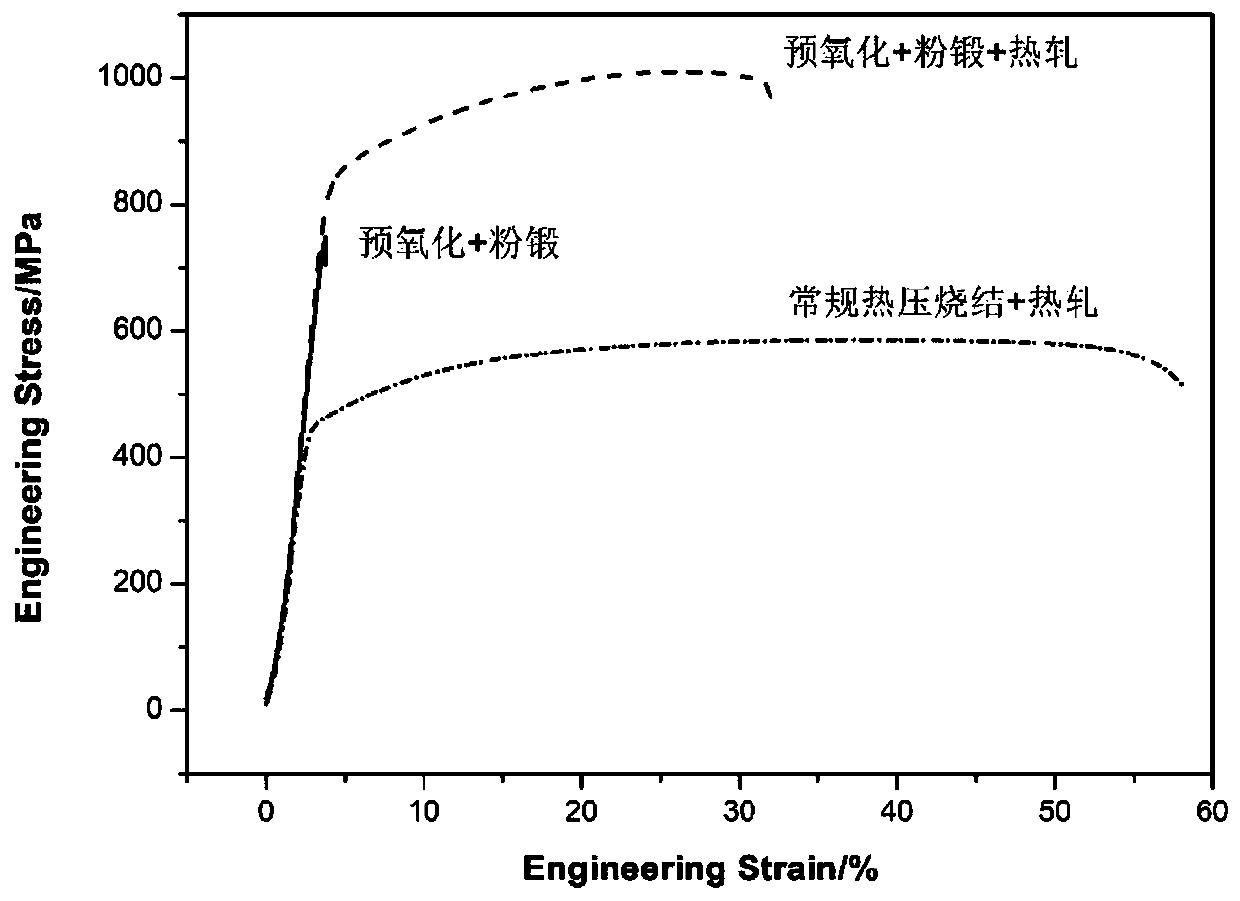

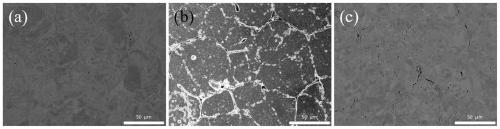

Powder metallurgy material for endophytic oxide strengthening alloy and preparation method thereof

The invention discloses a powder metallurgy material for an endophytic oxide strengthening alloy and a preparation method of the powder metallurgy material. The oxide strengthening alloy is directly prepared by utilizing the crushing effect of a powder forging process on an oxide film. Oxide is refined to be combined with a matrix at a crushing position of the oxide film, oxidation products are transferred into crystalline grain and are evenly distributed, the oxide film is well combined with the matrix, and an alloy material is further densified through thermal processing, and the prepared alloy has excellent properties such as high strength and good plasticity. The method requires no extra alloy element, and therefore the cost is low. Pre-oxidation treatment can be carried out on a largebatch of products at the same time without being limited by the load output capability of traditional vacuum hot-pressing sintering. The production process is simple. Requirements for production environment are low. The formed oxide is well combined with the matrix. Large-scale production is facilitated.

Owner:XI AN JIAOTONG UNIV

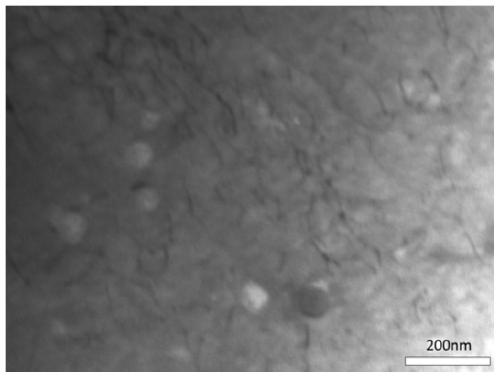

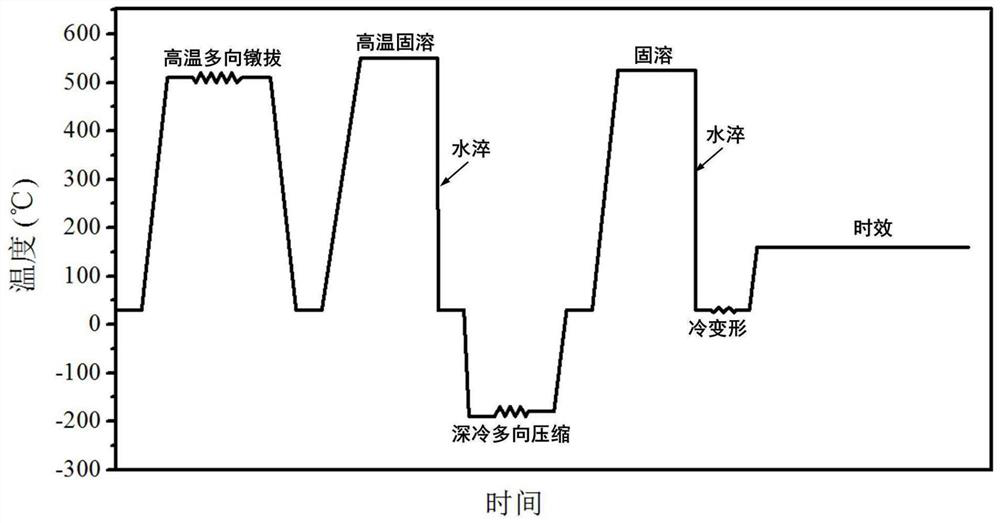

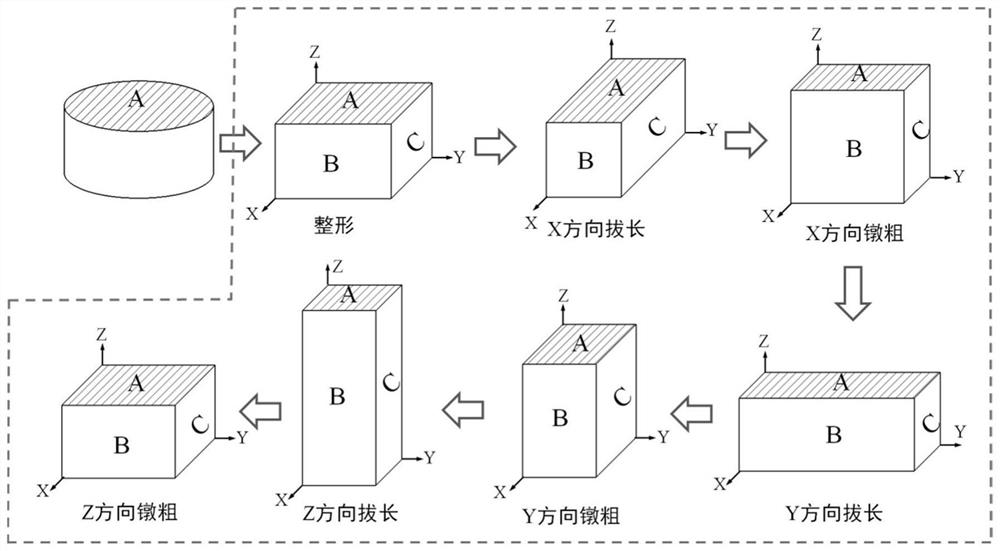

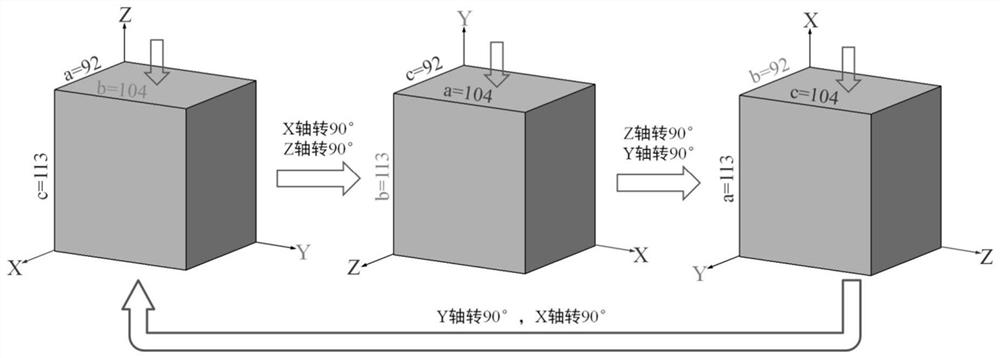

A preparation method of homogeneous fine-grained al-mg-si alloy mirror material

ActiveCN113512690BGood formabilityPrevent precipitationMetal-working apparatusSolution treatmentIngot

Owner:湖南卓创精材科技股份有限公司

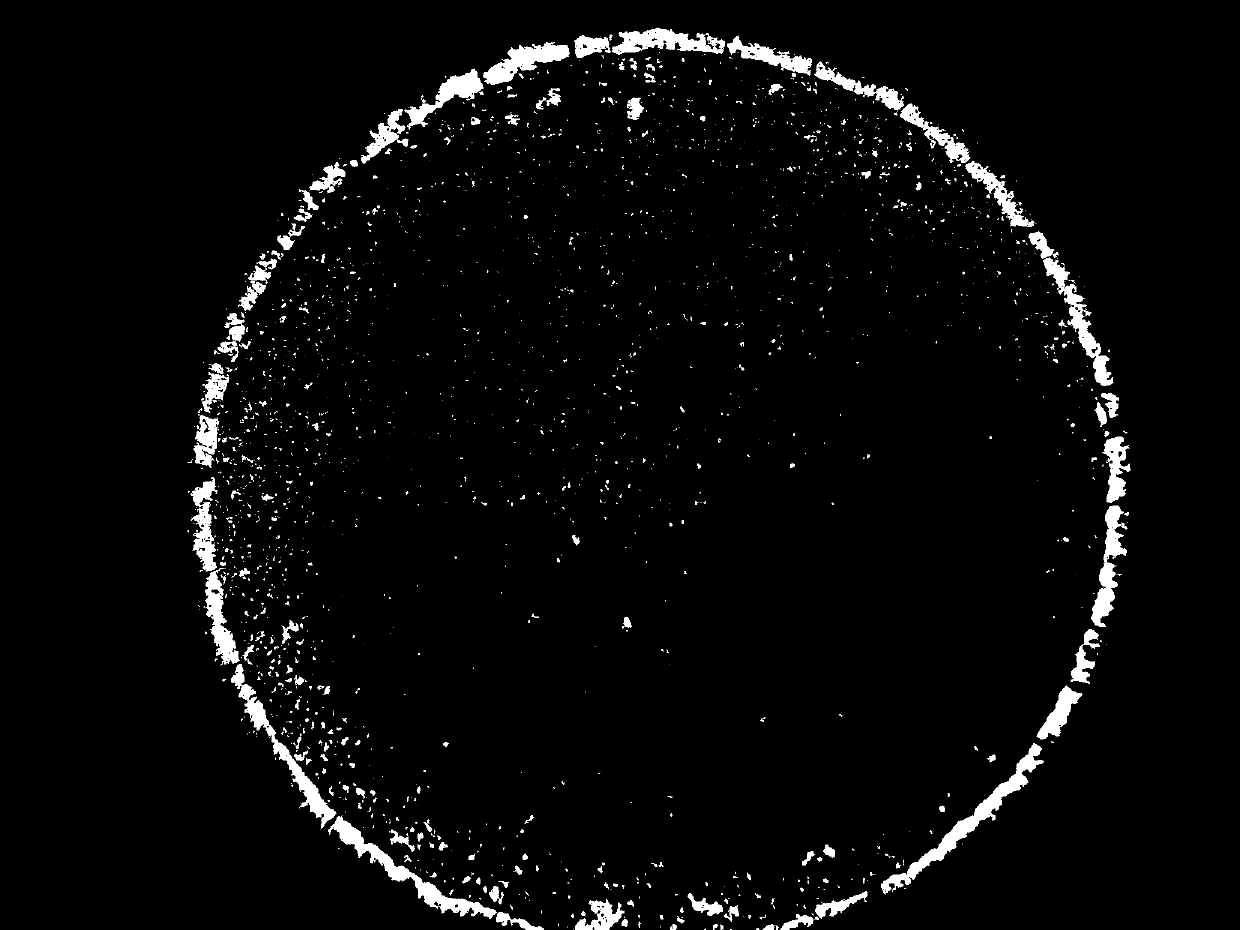

Negative electrode material for high intensity discharge lamp and manufacturing method thereof

ActiveCN103343275BIncrease in crystal defectsExtended service lifeGas discharge lamp detailsCold cathode manufactureManufacturing technologyThorium oxide

Owner:威海多晶钨钼科技有限公司

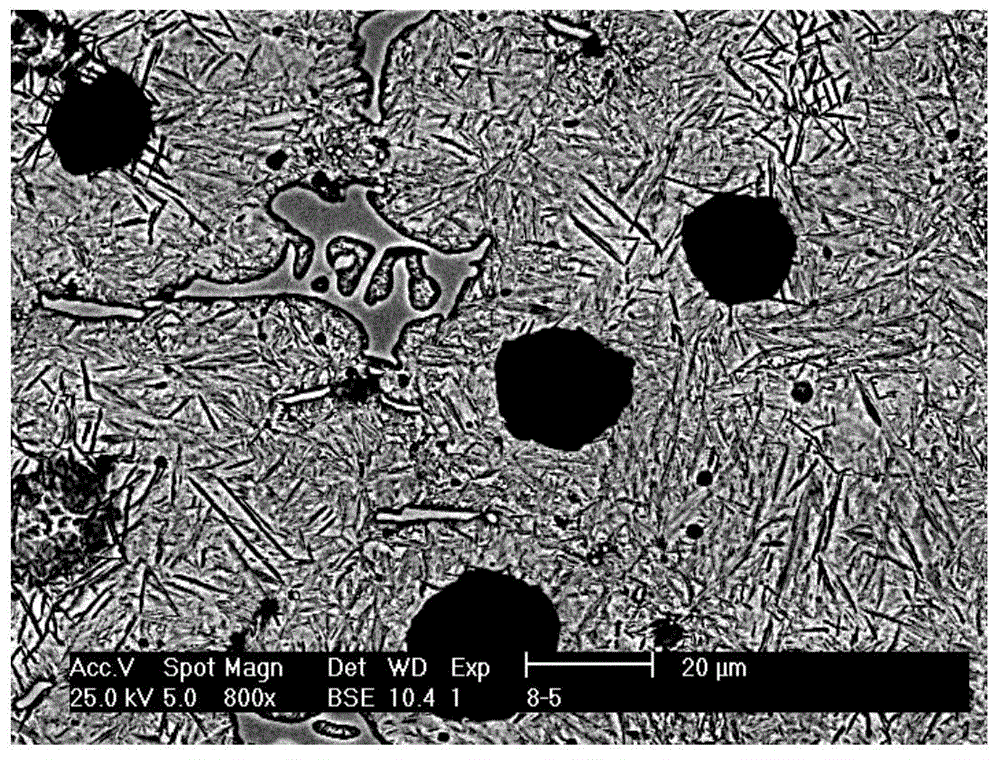

Process for producing and machining ausferrite nodular cast iron lining plate

InactiveCN110016608APrecise content controlUniformly distributed refinementRoom temperatureDuctile iron

The invention discloses a process for producing and machining an ausferrite nodular cast iron lining plate. The process comprises the following steps that raw materials are placed into a melting furnace to be heated till being completely molten, and the raw materials are molten into ausferrite nodular cast iron base iron melt and discharged from a furnace, wherein the base iron melt comprises, byweight, 2.8-3.4% of C, 2-2.6% of Si, 0.6-1.2% of Mn, 0.2-0.8% of Cr, 0.2-0.6% of Mo, 0.08-0.12% of B, 0.02-0.08% of Ti, 0.01-0.08% of V, 0.01-0.04% of P, 0.01-0.04% of S, 0.01-0.04% of Mg and the balance Fe; and the base iron melt is subjected to spheroidizing treatment, inoculation treatment and microalloying treatment in sequence, poured into a sand-coated metal mold, heated, insulated, quenchedinto a nitrate solution, placed for standing, and cooled to room temperature to obtain the ausferrite nodular cast iron lining plate. The process is simple, the cost is low, the product is good in wear resistance and not likely to be fractured, the volume hardness HRC can reach 61.42, the impact toughness can reach 9.12J / cm<2>, and the falling body impact fatigue life can reach 15000 times.

Owner:NINGGUO HUAFENG WEAR RESISTANT MATERIAL

A kind of austeric ductile iron grinding ball

The invention discloses an Ausferrite ductile cast iron grinding ball, and relates to a spherulitic graphite-contained cast iron alloy. The Ausferrite ductile cast iron grinding ball comprises the following chemical elements in percentage by mass: 3.3-3.7% of C, 2.0-3.0% of Si, 1.0-2.5% of Mn, 0.7-3.0% of Cr, 0.1-1.0% of Mo, 0.1-1.0% of Cu, 0.04-0.08% of P, 0.01-0.020% of S, 0.03-0.05% of Mg, 0.02-0.04% of Ce, 0.03-0.07% of B, 0.06-0.12% of Ti, 0.03-0.2% of V, and the balance of Fe. The Ausferrite ductile cast iron grinding ball is prepared by the steps of preparation and smelting of raw materials, spheroidizing treatment, inoculation treatment and microalloying treatment, and isothermal quenching heat treatment. The Ausferrite ductile cast iron grinding ball overcomes the defects of low production efficiency and high consumption of electric energy of a ball mill due to easy surface stripping and crushing and shorter fatigue life of an existing grinding ball product in the service process.

Owner:HEBEI UNIV OF TECH

Regulation and control method for ordered precipitation of precipitated phase of aluminum-lithium alloy in laser additive manufacturing

ActiveCN113385669AHigh strengthImprove tensile propertiesAdditive manufacturing apparatusIncreasing energy efficiencyMetallic materialsLaser additive manufacturing

The invention provides a regulation and control method for ordered precipitation of a precipitated phase of aluminum-lithium alloy in laser additive manufacturing. The regulation and control method for ordered precipitation of the precipitated phase of aluminum-lithium alloy in laser additive manufacturing comprises the following steps of: feeding an aluminum-lithium alloy material into a molten pool for printing layer by layer to form a printing layer; performing rolling deformation on each formed printing layer during layer-by-layer printing, regulating and controlling the distribution of the precipitated phase by controlling the deformation amount, and then printing the next layer until printing forming of the whole aluminum-lithium alloy workpiece is completed, wherein the deformation amount of each printing layer is 7%-9% large deformation amount; and performing solid solution aging treatment on the printed and formed aluminum-lithium alloy workpiece. According to the invention, the metal material is controlled to be printed layer by layer, and synchronously, large-deformation-amount rolling deformation is carried out on each layer of the Al-Li alloy, so that ordered precipitation of the precipitated phase is controlled, and intragranular reinforced phases are not gathered at the grain boundary position and arranged disorderly any more; and a T1 phase and a [theta]' phase are precipitated at the intragranular dislocation position, the grain size of the T1 phase is reduced, grain refinement and uniform distribution are promoted, and the comprehensive performance is improved.

Owner:NANJING UNIV OF TECH

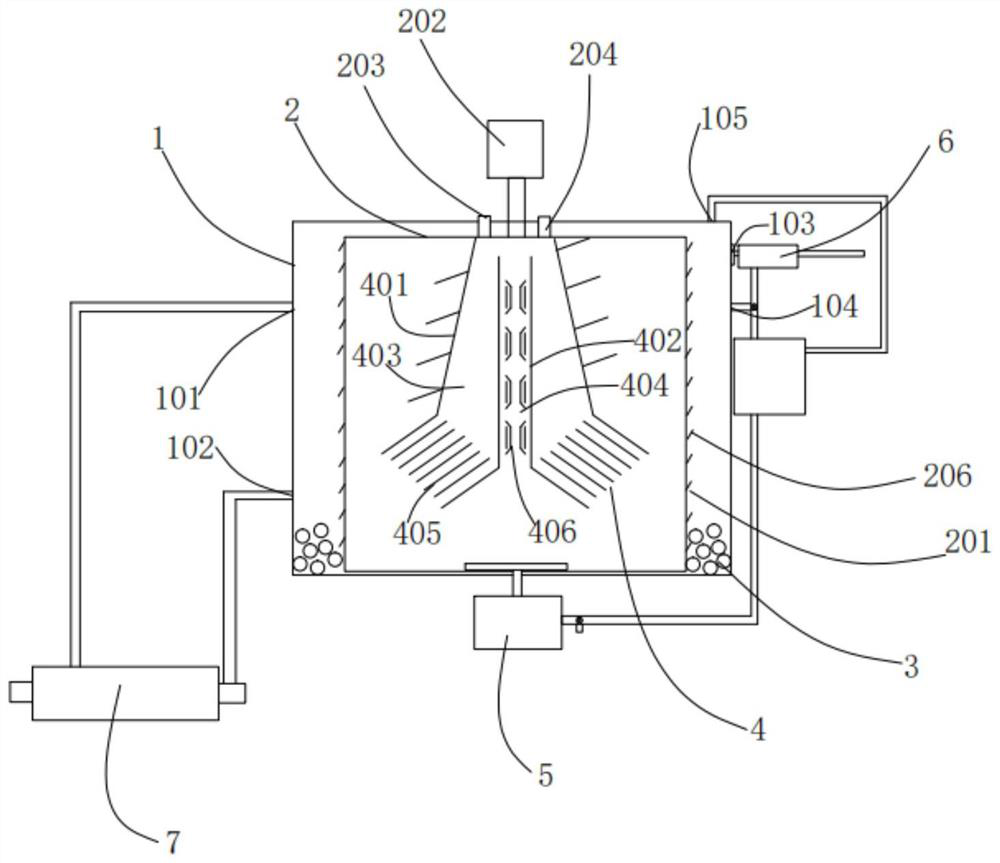

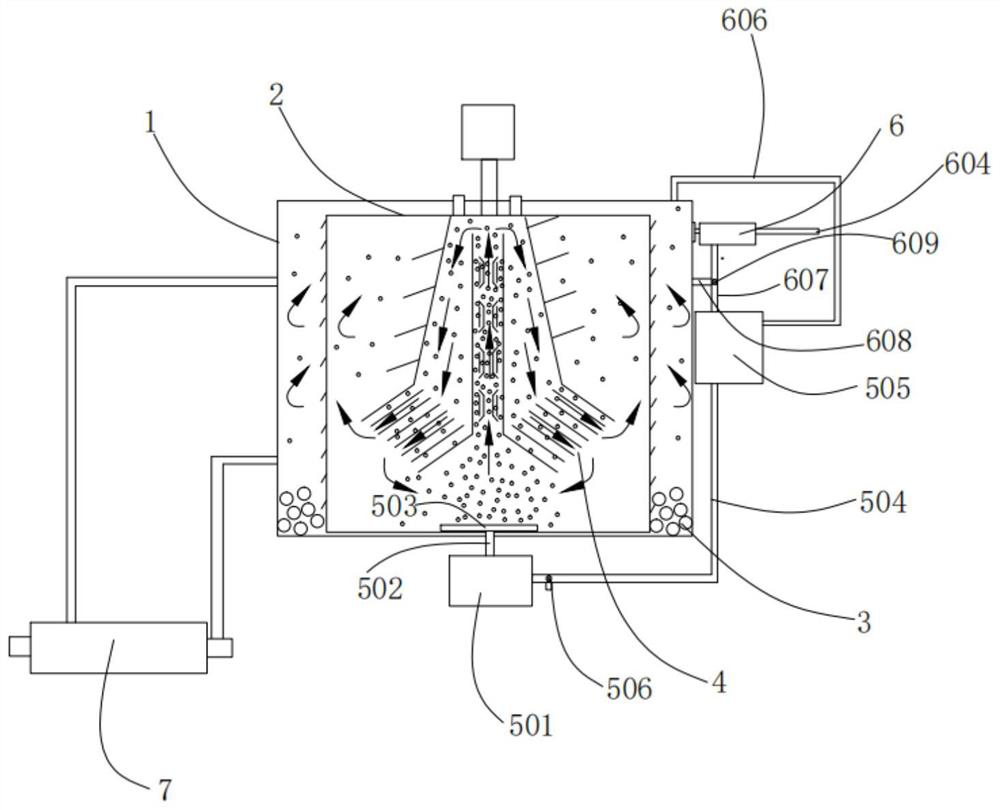

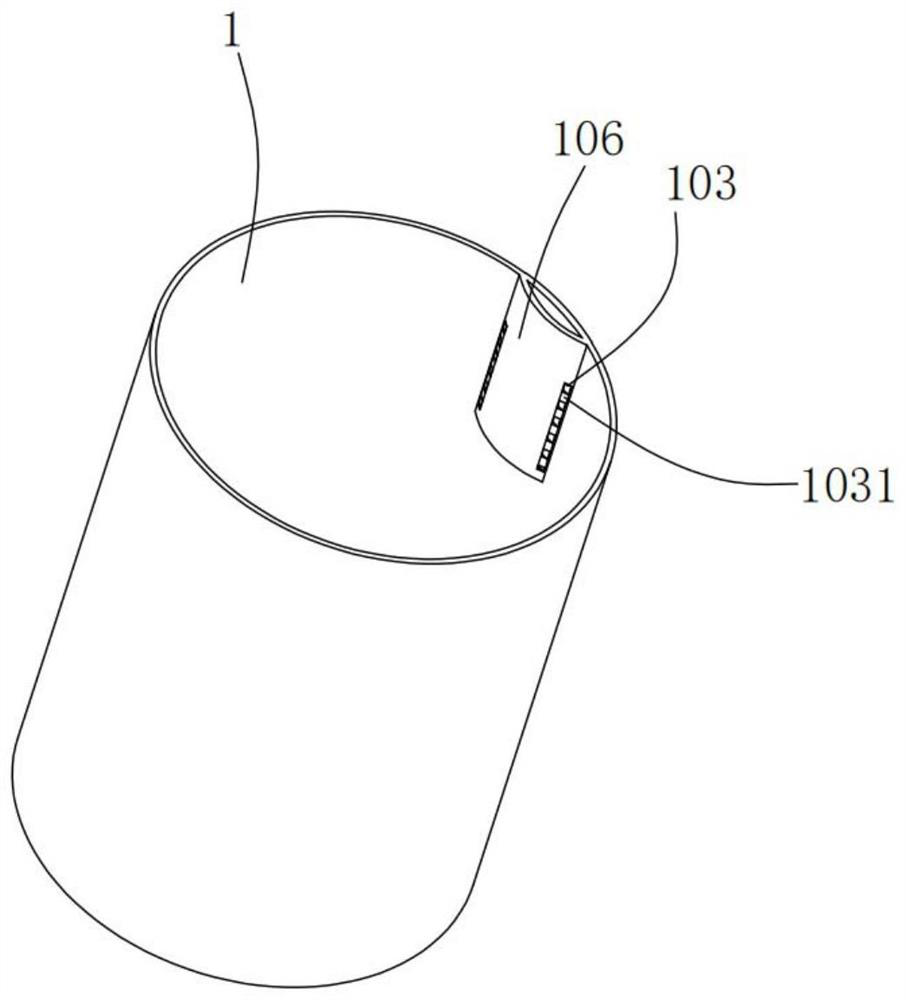

Waste paper raw material treatment device and use method thereof

ActiveCN114749081ARealize the collectionAchieve emissionsRotating receptacle mixersFlow mixersAdhesive beltProcess engineering

The invention provides a waste paper raw material treatment device and a use method thereof. The pulping device comprises an outer shell, a pulping device and a pulping device, the inner shell is rotatably arranged in the outer shell; the circulating flow guide assembly is arranged in the inner shell, the inner space of the circulating flow guide assembly is divided into a first circulating cavity and a second circulating cavity, the second circulating cavity is located in the center of the circulating flow guide assembly, and the first circulating cavity is an annular cavity arranged around the periphery of the second circulating cavity; the air supply assembly can be used for filling bubbles into the circulating flow guide assembly and forming a liquid flow which circularly flows between the first circulating cavity and the second circulating cavity in the circulating flow guide assembly; according to the waste paper raw material treatment device and the use method thereof, adverse effects caused by substances without a regeneration effect, such as plastic films and adhesive tapes, in the waste paper regeneration process can be overcome, and meanwhile, excessive shearing of a pulping device to paper pulp fibers in the waste paper regeneration process is avoided.

Owner:福建省闽清双棱纸业有限公司

Thorium tungsten wire used for winding microwave oven magnetron and manufacturing method of thorium tungsten wire

ActiveCN103346054BIncrease in crystal defectsSuppress coarseningTransit-tube cathodesCold cathode manufactureMicrowave ovenThorium oxide

The invention belongs to the technical field of metal material manufacturing, and particularly relates to a thorium tungsten wire used for winding a microwave oven magnetron and a manufacturing method of the thorium tungsten wire. The thorium tungsten wire is characterized by comprising 0.5-1.5% of thorium oxide, 0.0020-0.0080% of potassium and 97-98% of tungsten. Compared with the prior art, the thorium tungsten wire and the manufacturing method have the advantages that (1) according to the thorium tungsten wire, though 0.0020-0.0080% of the potassium is added, thorium oxide particles are still fine and uniform; (2) the thorium tungsten wire contains microelement potassium in content, after coils of the microwave oven magnetron wound through the thorium tungsten wire are carbonized at a high temperature, crystal grains cannot grow larger easily, organization stability is maintained, and the situation that the microwave oven magnetron cannot break due to shaking in the packaging and delivery transportation processes after being produced is guaranteed.

Owner:威海多晶钨钼科技有限公司

A method for strengthening aluminum alloy profile with nanocomposite material

The invention provides a method for reinforcing an aluminum alloy profile through a nano composite material. Al2O3 and carbon nanotubes in a specific proportion are dispersed under the assistance of microwave ball milling; after the nano composite material is formed, 1 / 2 of the nano composite material is mixed with aluminum alloy liquid, the dispersity among components and the uniformity of particle mixing are improved advantageously, and the specific surface area of mixing and the surface interaction force of mixing can be effectively increased. Finally, the remaining 1 / 2 of the nano composite material is added in a filling mode after aluminum alloy is sintered, the combination degree of the nano composite material and the aluminum alloy is reinforced through repeated heating and friction, refining and uniform distribution of crystal grains are further promoted, the crystal boundary stability is improved synergistically, the high strength and plasticity of the aluminum alloy are ensured, and the wear resistance of the aluminum alloy can further be improved significantly. The method for reinforcing the aluminum alloy profile through the nano composite material solves the internal defects of the nano composite material in the aluminum alloy on the whole, and solves the problem of coarse crystal grains of the aluminum alloy.

Owner:佛山市三水凤铝铝业有限公司 +1

Semi-high-speed shear steel

The invention discloses semi-high-speed shear steel. The semi-high-speed shear steel is composed of following chemical elements including, by weight, 0.66-0.7% of C, 0.35-0.5% of Si, 0.3-0.42% of Mn, 5.5-7% of Cr, 1.5-2.7% of W, 4.5-5% of Mo, 1-1.2% of V, 0.13-0.21% of Nb, 0.5-0.55% of Co, 0-0.01% of S, 0-0.02% of P, and the balance Fe. A copper-brazed steel-inlaid paper cutting blade prepared from the semi-high-speed shear steel has the same hardness as an original copper-brazed steel-inlaid paper cutting blade prepared from high-speed steel, but is higher in sharpness and easy to sharpen. Besides, material cost and process cost are reduced.

Owner:CHONGQING LINGYUN TOOLS CO LTD

A preparation method of functionally graded materials based on friction stir welding

InactiveCN108608108BReduce manufacturing costAvoid crackingNon-electric welding apparatusFriction weldingMechanical property

The invention discloses a preparation method of a gradient functional material based on friction-stir welding. The preparation method comprises the following steps: adding a reinforced phase materialto a substrate by means of a right-angled triangular prism groove structural design on the substrate; and generating heat by mutual friction of a stirring head and a material in a substrate welding region, wherein the substrate welding region is softened plastically and the material in the substrate welding region drives the reinforced phase material to flow plastically under the action of the stirring head, so as to form a uniform gradient functional material from the material in the substrate welding region and the reinforced phase material. The method disclosed by the invention does not need special environments such as vacuum, temperature, electric field and magnetic field, and is low in preparation cost; by means of a solid state processing mode, formation of cracks, pores and oxidesin the material can be avoided effectively, and the gradient functional material which is high in compactness and uniform to mix can be obtained. Various types of gradient functional materials can beprocessed; the preparation method is a green processing technology, and the gradient functional material which is higher in mechanical property can be obtained.

Owner:JILIN UNIV

A kind of preparation method of ultrasonic mg-al-zn-mn-nd corrosion-resistant rare earth magnesium alloy

A preparation method of an ultrasonic Mg-Al-Zn-Mn-Nd corrosion resistant rare earth magnesium alloy comprises the steps: putting a Mg-Al-Zn-Mn series alloy into a crucible with the furnace temperatureof 730-750 DEG C, heating and melting, adding small block Mg-20% Nd intermediate alloy wrapped by aluminum-foil paper, and carrying out heat preservation until the alloy is melted completely; then extending an ultrasonic amplitude-change pole into the alloy melt, and carrying out intermittent ultrasonic treatment, wherein the intensity is 1000-2000 W, the intermittent ultrasonic treatment is performed for 15-20 s each time and is performed every other 15-20 s, and the total time is 700-900 s; and finally, rapidly pouring into a preheated metal die, wherein the obtained alloy comprises the components by the weight percentage: 7.0-9.1% of aluminum, 1.2-1.5% of zinc, 0.7-0.9% of manganese, 0.5-1.5% of neodymium, and the balance magnesium. A second phase structure of the alloy is more uniformin distribution, a cathode phase with low self-corrosion potential is formed by addition of rare earth elements, and the whole corrosion performance of the alloy is greatly improved.

Owner:镁高镁诺奖(铜川)新材料有限公司

Semi-high-speed steel

The invention discloses semi-high-speed steel. The semi-high-speed steel is composed of, by weight, 0.56%-0.65% of C, 0.40%-0.60% of Si, 0.25%-0.40% of Mn, 6.0%-6.8% of Cr, 1.6%-2.5% of W, 4.2%-5.2% of Mo, 0.7%-0.9% of V, 0.1%-0.2% of Nb, 0.3%-0.4% of Co, 0-0.02% of S, 0-0.025% of P, and the balance Fe. The strength of a paper cutting blade made from the semi-high-speed steel is identical with that of an original high-speed steel copper brazing steel plated paper cutting blade, but the paper cutting blade made from the semi-high-speed steel is higher in sharpness and easy to sharpen, and the material cost and process cost are reduced.

Owner:CHONGQING LINGYUN TOOLS CO LTD

Semi-high speed steel shear steel

The invention discloses semi-high speed steel shear steel and belongs to the technical field of mechanical blades. The semi-high speed steel shear steel comprises, by weight, 0.56-0.65% of C, 0.40-0.60% of Si, 0.25-0.40% of Mn, 6.0-6.8% of Cr, 1.6-2.5% of W, 4.2-5.2% of Mo, 0.7-0.9% of V, 0.1-0.2% of Nb, 0.3-0.4% of Co or Ni, S<=0.02%, P<=0.025% and the balance Fe. The hardness of copper brazing steel plated paper cutting blades prepared by the semi-high speed steel shear steel is identical with that of the existing high speed steel copper brazing steel plated paper cutting blades, but the blades are higher in sharpness and easy to grind, and material and process costs are reduced.

Owner:ANHUI JIALONG KNIVES MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com