A preparation method of homogeneous fine-grained al-mg-si alloy mirror material

A fine-grained and alloyed technology is applied in the field of preparation of ultra-fine-grained and homogeneous Al-Mg-Si alloy mirror materials, which can solve the problems of inability to meet the use requirements of mirror alloys, large residual stress of materials, and easy formation of oxide films. To achieve the effect of improving plasticity, improving composition uniformity, and improving deformation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

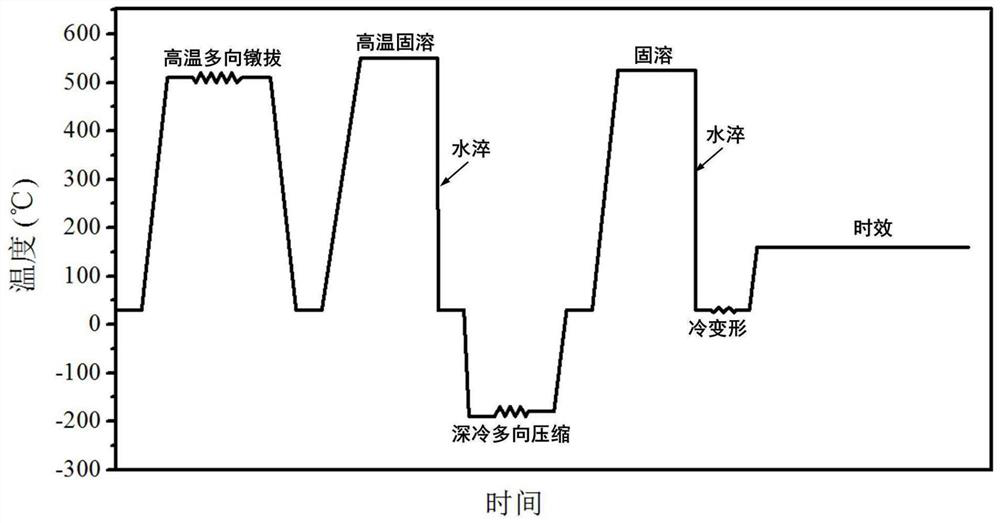

[0042] A kind of preparation method of homogeneous fine-grained Al-Mg-Si alloy mirror surface material of the present invention, its process flow chart is as figure 1 As shown, the specific steps are as follows:

[0043] (1) High temperature multi-directional upsetting:

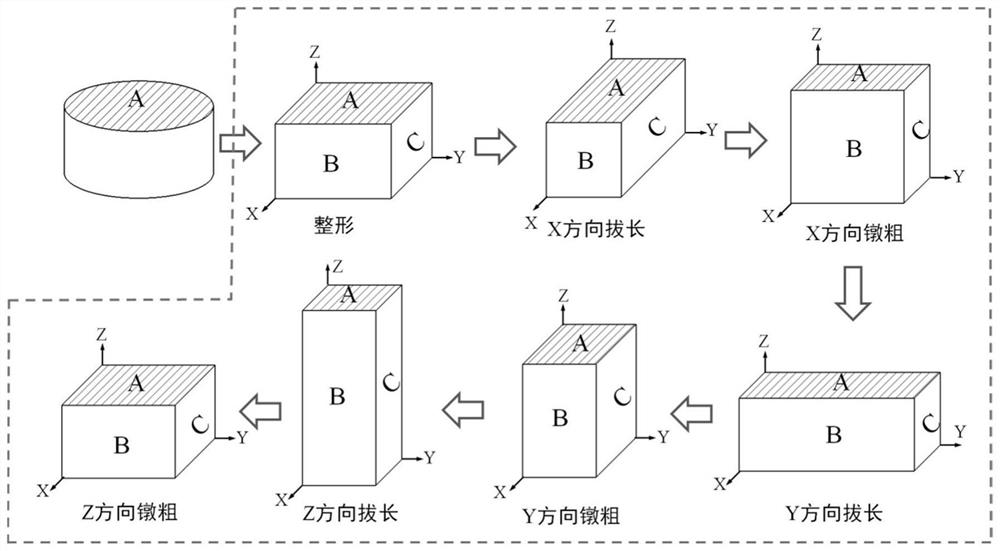

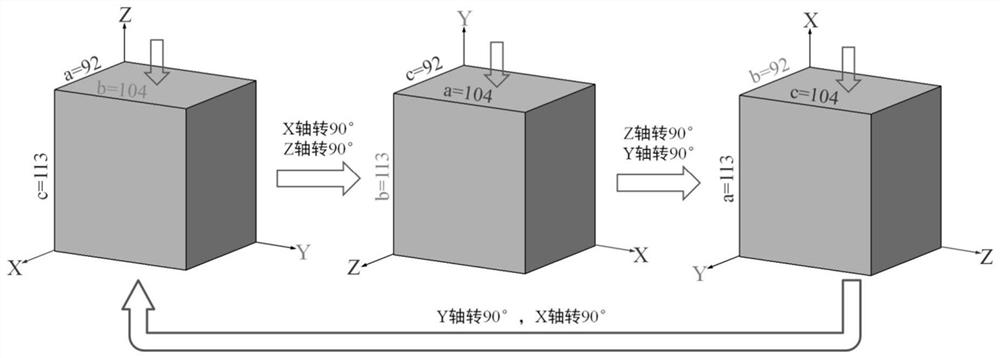

[0044] Take a homogenized 6061 aluminum alloy ingot Multi-directional upsetting is carried out on a 40MN CNC press. Before forging, the alloy ingot is heated to 510°C±10°C with the furnace (connected to a thermocouple to measure the temperature). After the alloy ingot reaches the furnace temperature, it is kept for 4 hours, and the mold is evenly heated. Permeable to 400 ~ 450 ° C. After the alloy ingot and the mold are heated, the mold is hoisted to the free forging press and connected by bolts, and then the alloy ingot is taken out and pressed on the press. figure 2 Perform multidirectional upsetting. The alloy ingot used in this experiment is cylindrical. The first step is to shape the ingot into a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com