Regulation and control method for ordered precipitation of precipitated phase of aluminum-lithium alloy in laser additive manufacturing

An aluminum-lithium alloy and laser additive technology, applied in the field of aluminum-lithium alloy, can solve the problems of dendrite coarsening, uneven element distribution, and affecting the comprehensive performance of Al-Li alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

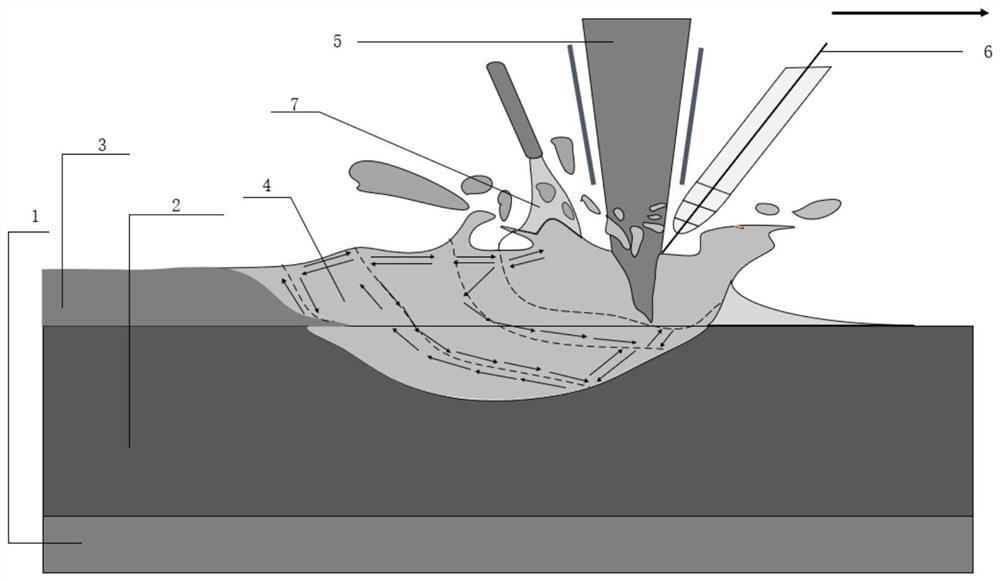

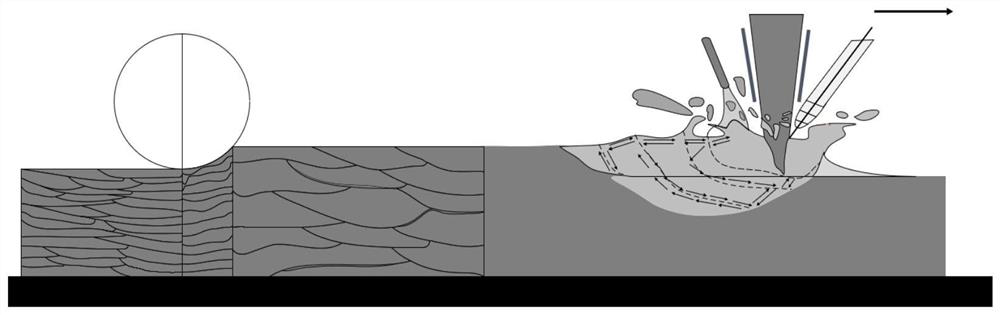

Method used

Image

Examples

Embodiment 1

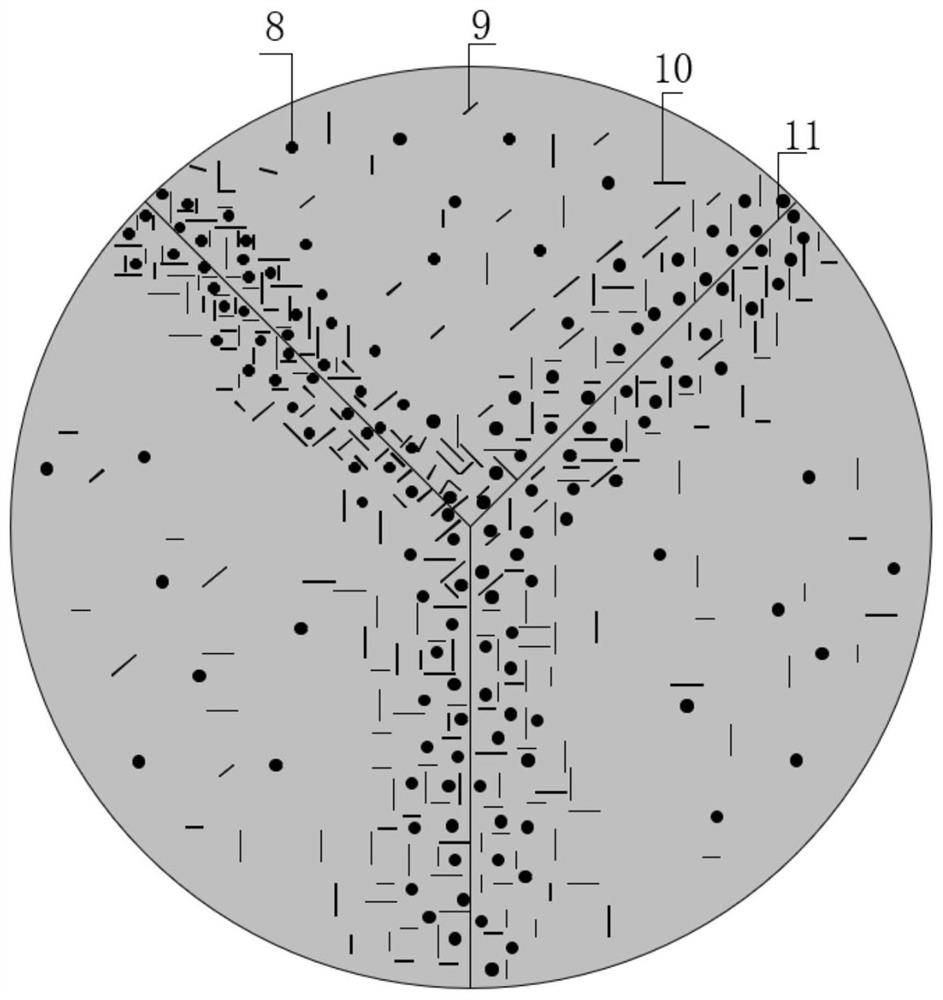

[0041] The rolling deformation is controlled at 3%. During the rolling process, dislocations are generated in the grain of the Al-Li alloy, and the θ' phase, T 1 During deformation and solid solution, phases precipitate at intragranular dislocations. Among them, θ' phase, T 1 The number of phases in the Al-Li alloy without rolling deformation increases to varying degrees, and the diameter of the θ' phase also decreases correspondingly with that of the Al-Li alloy without rolling deformation, T 1 Phase increase is greater than that of θ' phase. The schematic diagram of the structure distribution of Al-Li alloy is as follows: Figure 4 shown.

Embodiment 2

[0043] The rolling deformation is controlled at 5%, and the dislocations inside the Al-Li alloy grains will proliferate during the rolling process, and the θ' phase, T 1 The phase will continue to precipitate at the dislocation, so the θ'phase, T 1 Phase quantity and rolling deformation of 3% θ' phase, T 1 The number of phases increased to varying degrees, T 1 The phases are uniformly distributed, and the schematic diagram of the distribution of the Al-Li alloy is shown in Figure 5 shown.

Embodiment 3

[0045] When the rolling deformation is controlled to 7%, intragranular dislocations will further multiply, but due to the increase of deformation, a large number of intragranular dislocations are entangled, which hinders the proliferation of dislocations. Therefore, θ' phase, T 1 The number of phases increases at a slower rate, T 1 When the phase size and rolling deformation are 5% T 1 The grain size of the phase decreases and the distribution is uniform and dispersed. The schematic diagram of the structure distribution of its Al-Li alloy is shown in Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com