Stainless steel seamless tube and preparation method and application thereof

A seamless pipe and stainless steel technology, applied in the field of stainless steel seamless pipe and its preparation, can solve the problem of inability to produce seamless steel pipes with large diameter and uniform internal structure at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The outer diameter specification of the large-diameter austenitic stainless steel pipe prepared in this embodiment is 813mm×15mm×5000mm.

[0049] Firstly, the steel ingot is smelted by AOD furnace plus electroslag remelting process, and the steel billet is prepared by forging. The chemical composition of the billet is (mass percentage): C 0.045, Si 0.35, Mn 1.56, P 0.010, S 0.001, Ni 12.35, Cr17.45, Co 0.015, H 0.0004, B 0.0012, N 0.060, Fe balance. Class A non-metallic inclusions in steel billets are grade 0, class B non-metallic inclusions are 0.5, class C non-metallic inclusions are 0.5, and class D non-metallic inclusions are 1.0. Growing up has beneficial effects.

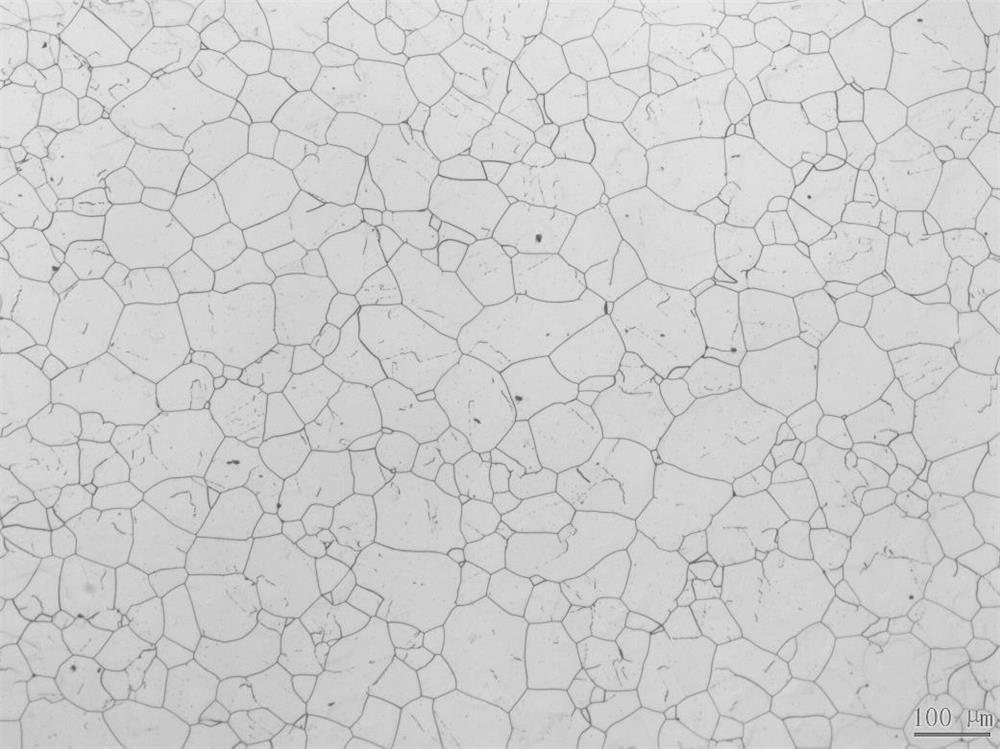

[0050] The steel billet is prepared by vertical hot extrusion process. The temperature of the hot extrusion process is 1250 °C, and the specification of the extruded tube is 813mm×15mm×5000mm. , the extrusion ratio is 5.2, the average grain size of the vertical hot extrusion blank tube is 150μm, a...

Embodiment 2

[0059] The outer diameter specification of the large-diameter austenitic stainless steel pipe prepared in this embodiment is 610mm×10mm×6000mm.

[0060] Firstly, the steel ingot is smelted by AOD furnace plus electroslag remelting process, and the steel billet is prepared by forging. The chemical composition of the billet is (mass percentage): C 0.045, Si 0.35, Mn 1.25, P 0.015, S 0.001, Ni 12.5, Cr17.32, Co 0.012, H 0.0005, B 0.0015, N 0.070, Fe balance. Class A non-metallic inclusions in steel billets are grade 0, class B non-metallic inclusions are 0.5, class C non-metallic inclusions are 0, and class D non-metallic inclusions are 0.5. Growing up has beneficial effects.

[0061] The main manufacturing process steps are as follows:

[0062] The steel billet is prepared by a vertical hot extrusion process. The temperature of the hot extrusion process is 1230 ° C, and the specification of the extruded tube is 680×25mm, the extrusion ratio is 7.2, the average grain size o...

Embodiment 3

[0069] The outer diameter specification of the large-diameter austenitic stainless steel pipe prepared in this embodiment is 850mm×15mm×5000mm.

[0070] Firstly, the steel ingot is smelted by AOD furnace plus electroslag remelting process, and the steel billet is prepared by forging. The chemical composition of the billet is (mass percentage): C 0.017, Si 0.235, Mn 1.03, P 0.0275, S 0.0012, Ni 9.85, Cr19.44, Co 0.015, H 0.0004, B 0.009, N 0.110, Fe balance. Class A non-metallic inclusions in steel billets are grade 0, class B non-metallic inclusions are 0.5, class C non-metallic inclusions are 0.5, and class D non-metallic inclusions are 1.0. Growing up has beneficial effects.

[0071] The blank tube is prepared by vertical hot extrusion process for the steel billet, the temperature of the hot extrusion process is 1200°C, and the specification of the extruded tube is 880×29mm, the extrusion ratio is 15.1, the average grain size of the vertical hot extrusion blank tube is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com