Waste paper raw material treatment device and use method thereof

A technology for raw material treatment and waste paper, applied in separation methods, post-treatment of mixtures, chemical instruments and methods, etc., can solve the problems of increasing waste paper recycling costs, reducing pulp fluidity, and cumbersomeness, so as to improve uniformity and realize fiber The effect of thinning and even distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the above objects, features and advantages of the present invention more clearly understood, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

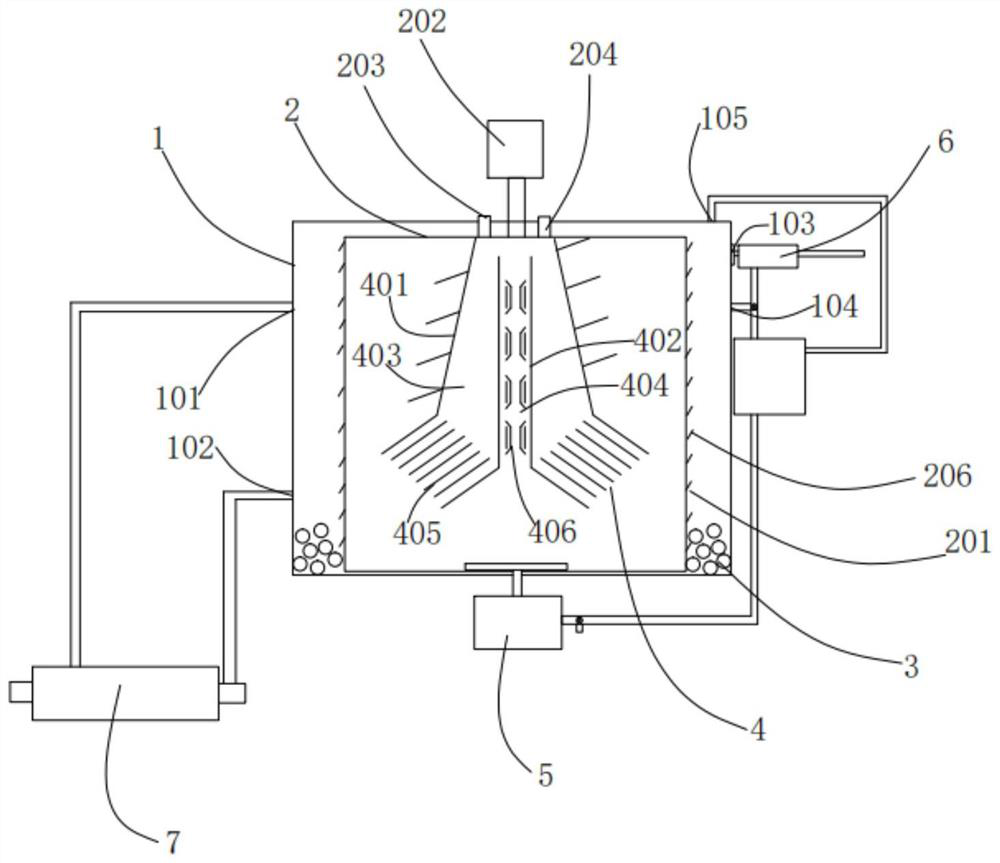

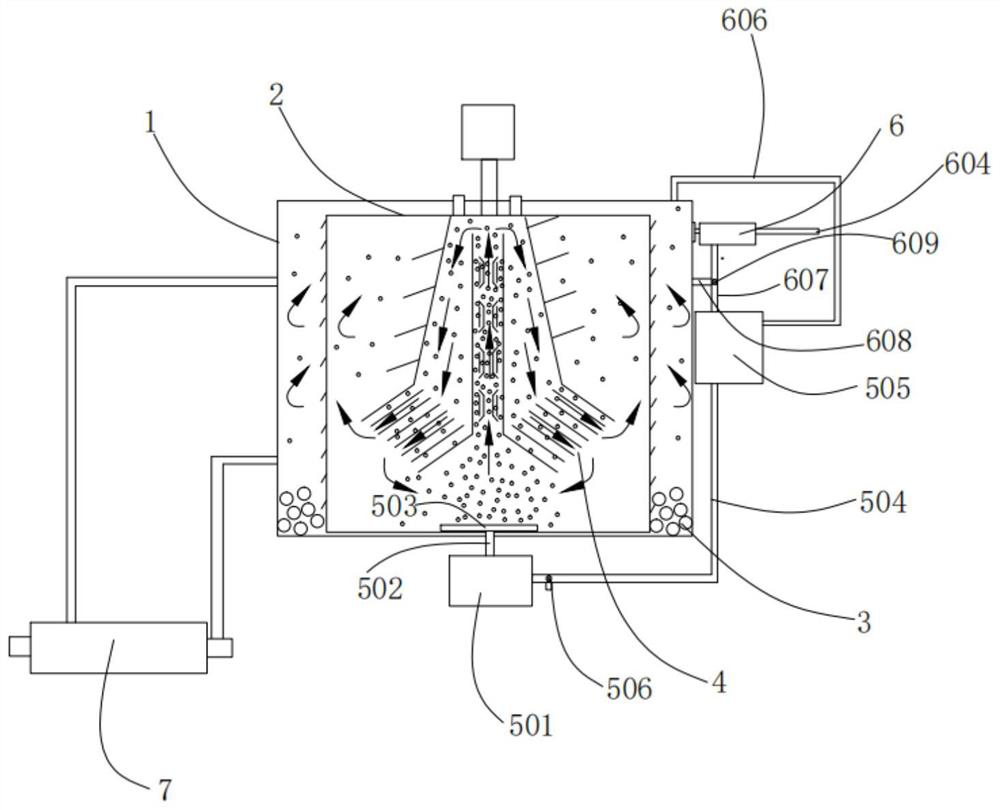

[0072] like Figures 1 to 17 As shown, a waste paper raw material processing device includes:

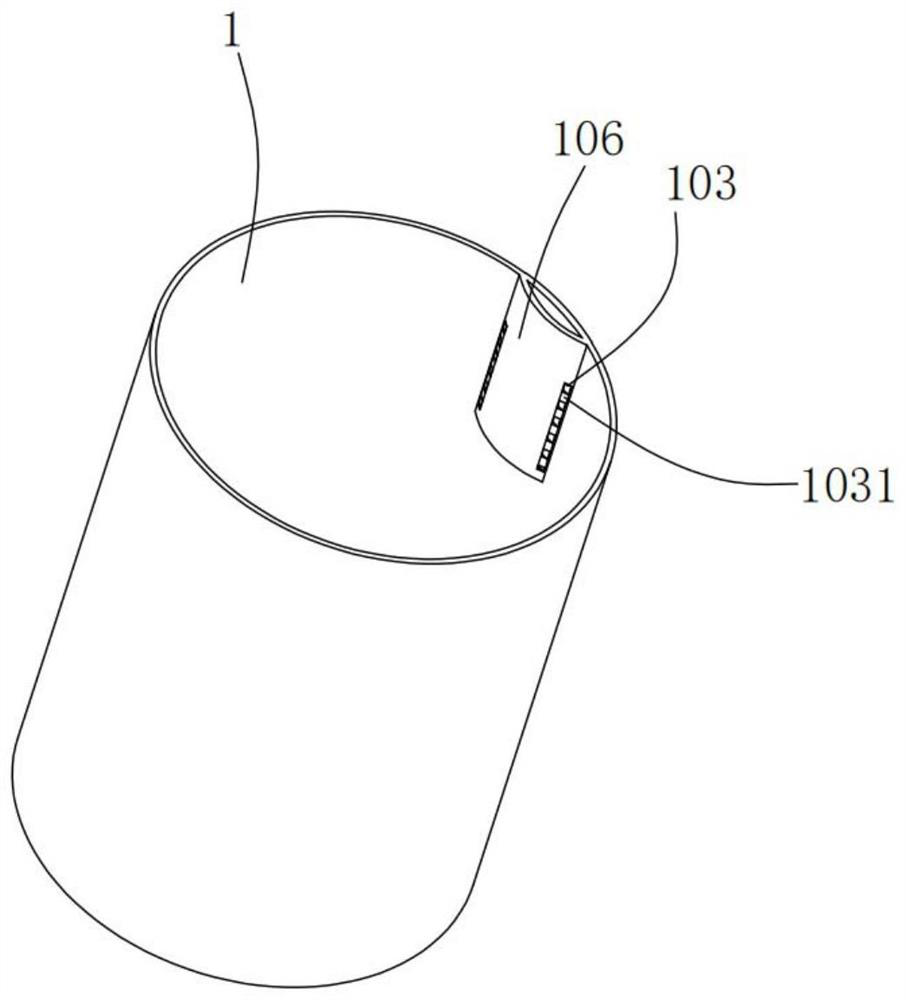

[0073] an outer casing 1, which constitutes the outer wall of the waste paper raw material processing device;

[0074] an inner casing 2, which is rotatably arranged in the outer casing 1;

[0075] The circulation guide assembly 4 is arranged in the inner casing 2, and the inner space of the circulation guide assembly 4 is separated to form a first circulation cavity 403 and a second circulation cavity 404, wherein the second circulation cavity 404 Located in the center of the circulation guide assembly 4, the first circulation cavity 403 is an annular cavity arranged around the periphery of the second circulation cavity 404;

[0076] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com