Micro-arc oxidation process method for pre-treating aluminum alloy based on solution and aging

A technology of micro-arc oxidation and solid solution aging, which is applied in anodic oxidation and other directions, can solve the problems of reducing the performance of the oxide film layer and increasing the roughness of the oxide film layer, and achieves uniform and fine distribution of the strengthening phase, good bonding, and improved surface performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

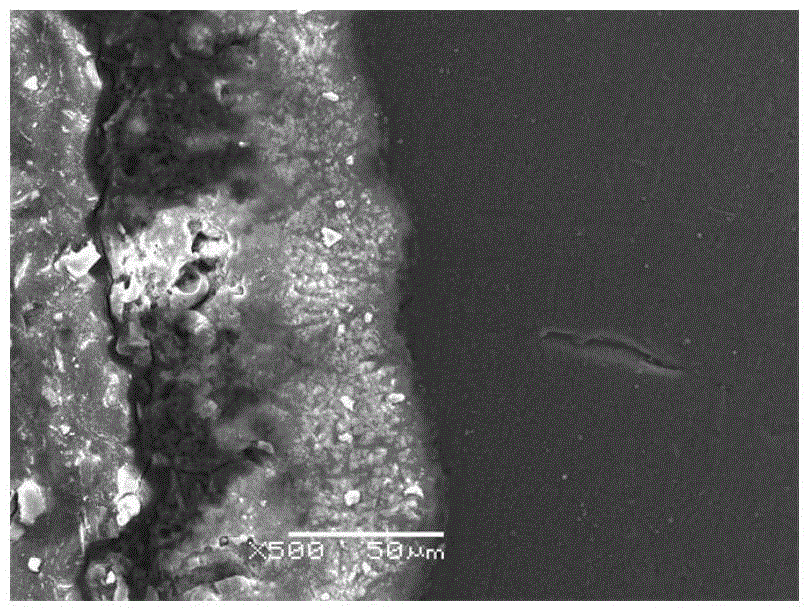

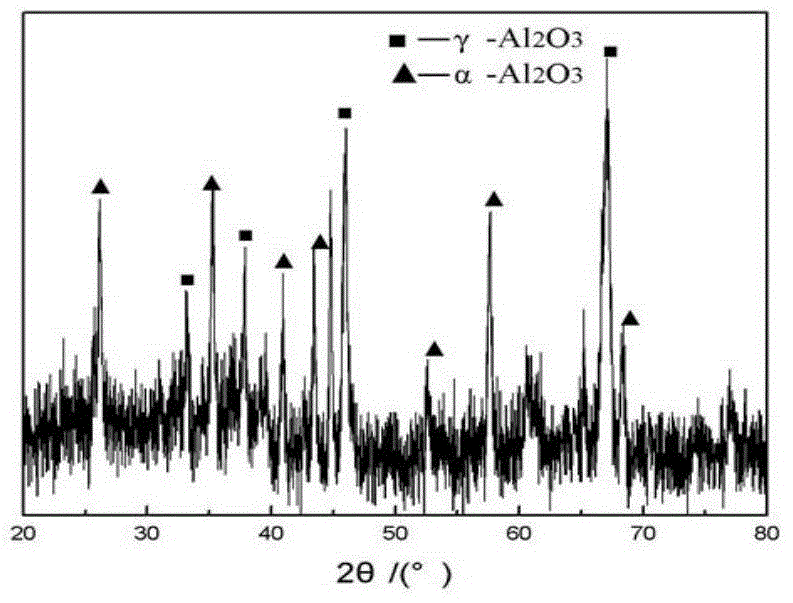

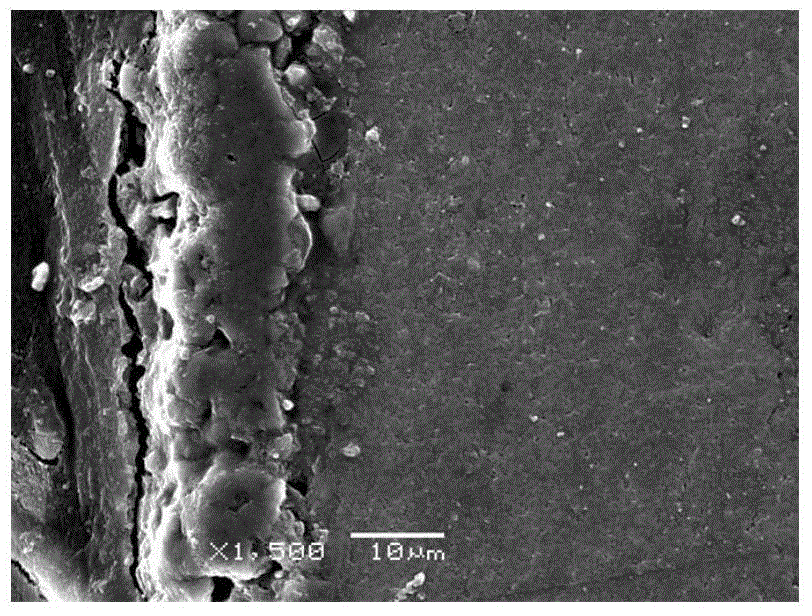

[0039] In order to better illustrate the effect of the process method provided by the present invention, the 6063 aluminum alloy is subjected to solution treatment: 515°C, heat preservation for 55min, furnace cooling; aging treatment: 215°C, heat preservation for 4h, air cooling. The concentration of each component in the electrolyte is, Na 2 SiO 3 : 6g / L; NaOH: 1g / L; NaF 1.0g / L; CoSO 4 0.6g / L. Electrical parameter setting: positive voltage 44V 0; positive voltage frequency 280Hz; positive voltage duty cycle 55%; negative voltage 100V; negative voltage frequency 110Hz; negative voltage duty cycle 30%; ~90μm, mainly composed of α-Al 2 o 3 phase and γ-Al 2 o 3 Dense ceramic membranes composed of phases, such as Figure 1-2 shown.

[0040] Through experimental observation, without solution aging treatment, the thickness of aluminum alloy micro-arc oxidation ceramic layer is relatively thin, but the thickness of the aluminum-impregnated layer obtained after the process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com