Crack resolution detection method

A detection method and resolution technology, applied in the detection field, can solve problems such as poor repeatability, inconvenient testing, and scattered data, and achieve the effects of convenient testing, good reproducibility, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

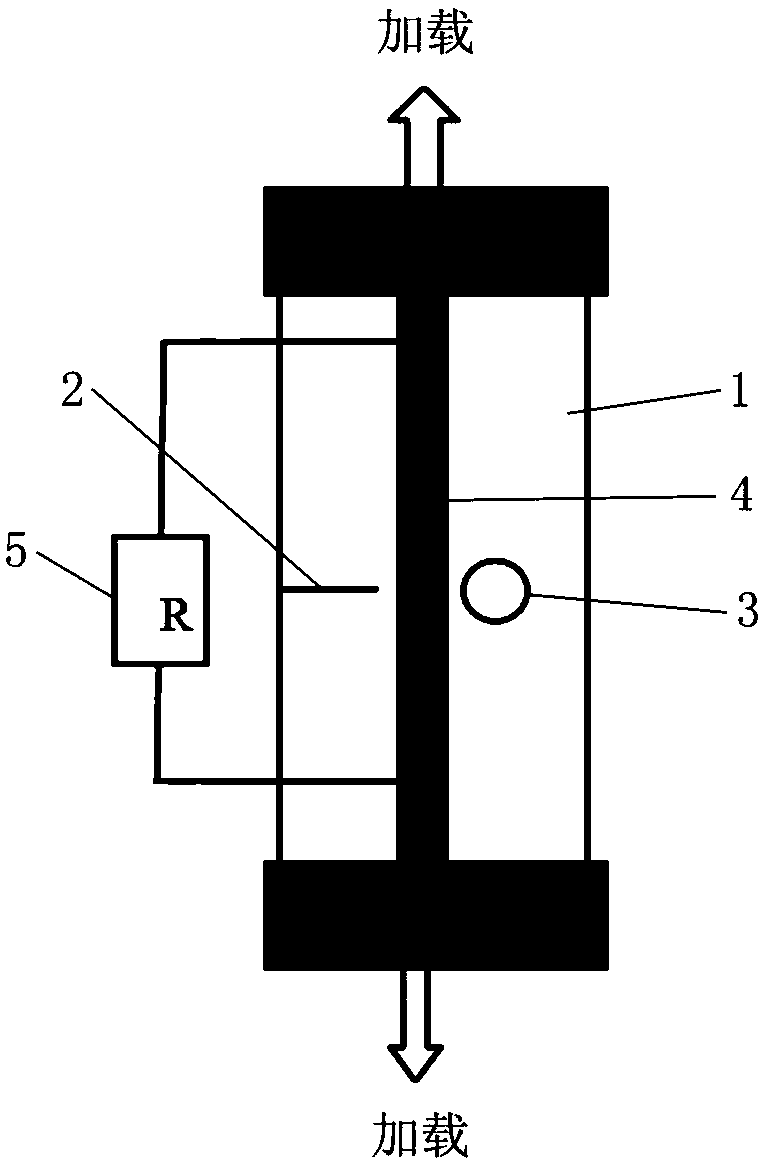

[0022] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Like reference numerals refer to like parts throughout the specification.

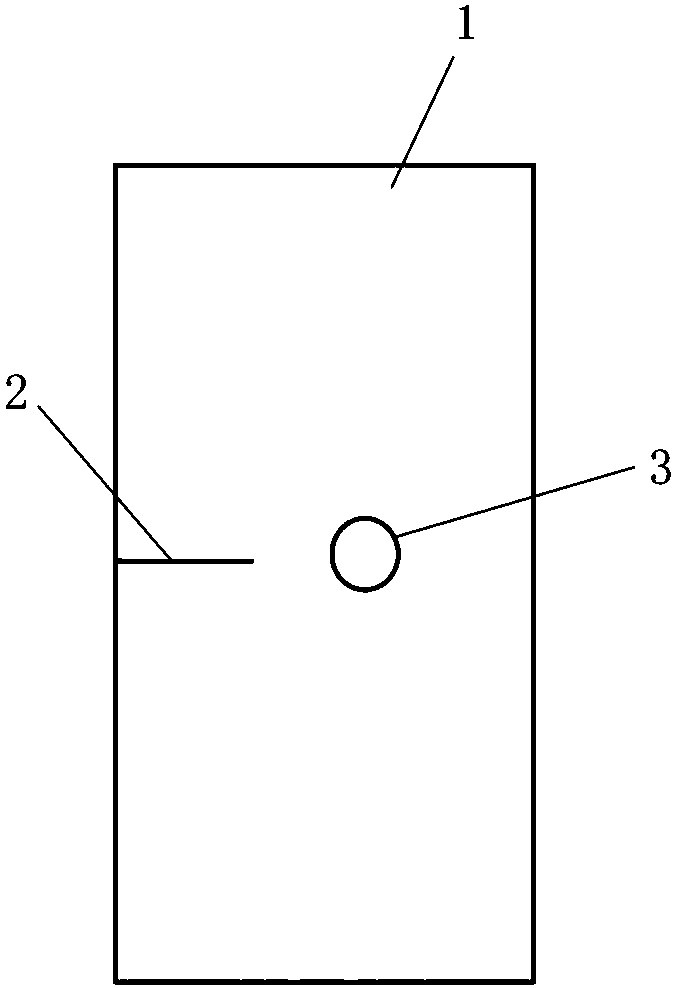

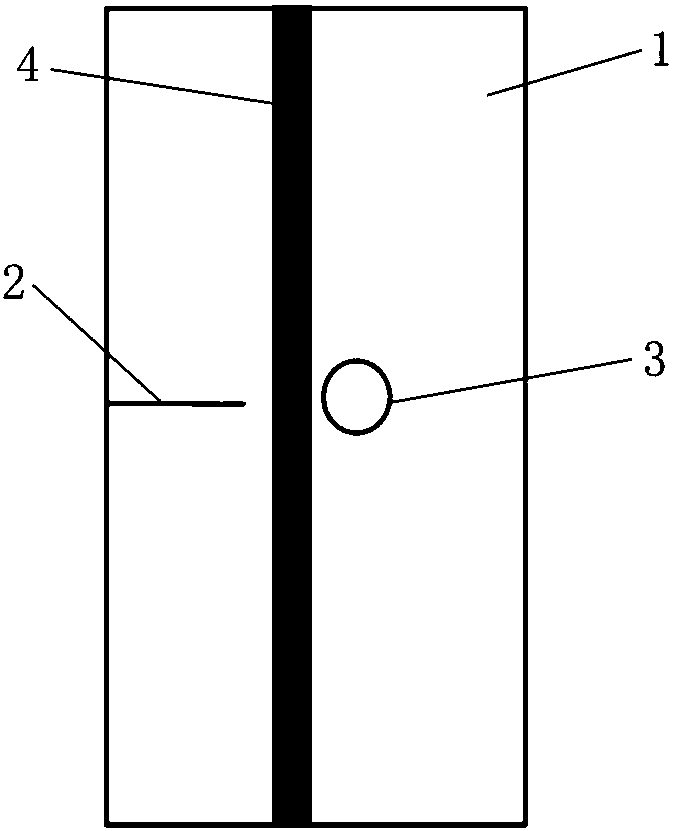

[0023] figure 1 is a diagram of a target sample 1 to be tested prepared by a crack resolution detection method according to an exemplary embodiment of the present invention.

[0024] Such as figure 1 As shown, the shape of the tested target sample 1 prepared according to the crack resolution detection method of an exemplary embodiment of the present invention can be determined according to the shape of the measured target and the loading situation, for example, when the measured target When it is a pitch bearing, since the pitch bearing mainly bears circumferential force and produces cracks, it is only necessary to consider the stress per unit area of the cross section of the pitch bearing, that is to say, the thickness, width and The curvature has little effect on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com