Patents

Literature

32results about How to "Bs high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

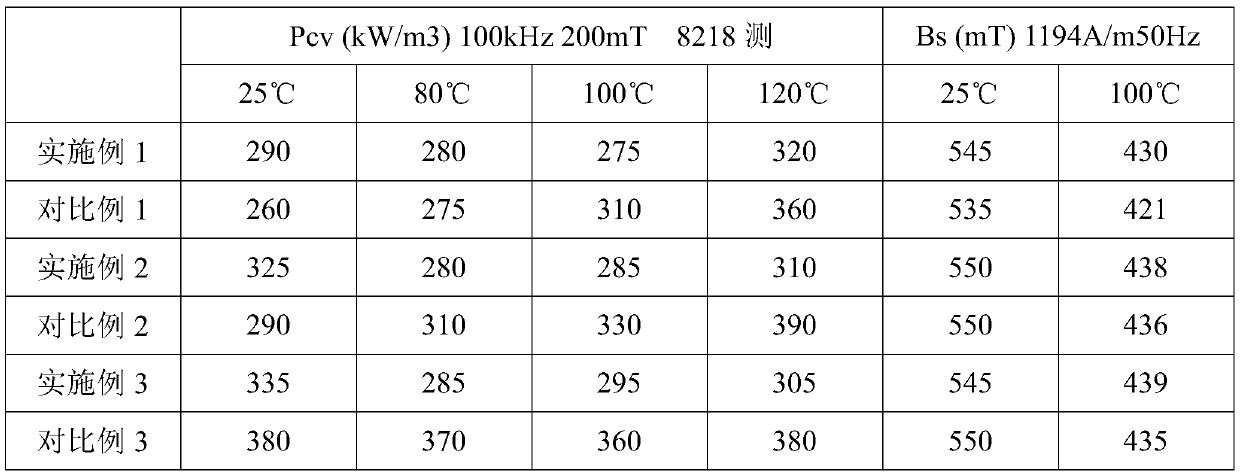

Ni-free MnZn ferrite magnetic core with double characteristics and manufacture method

ActiveCN103496963AOvercome the inability to take into account multiple featuresImprove performanceFerrite (magnet)Condensed matter physics

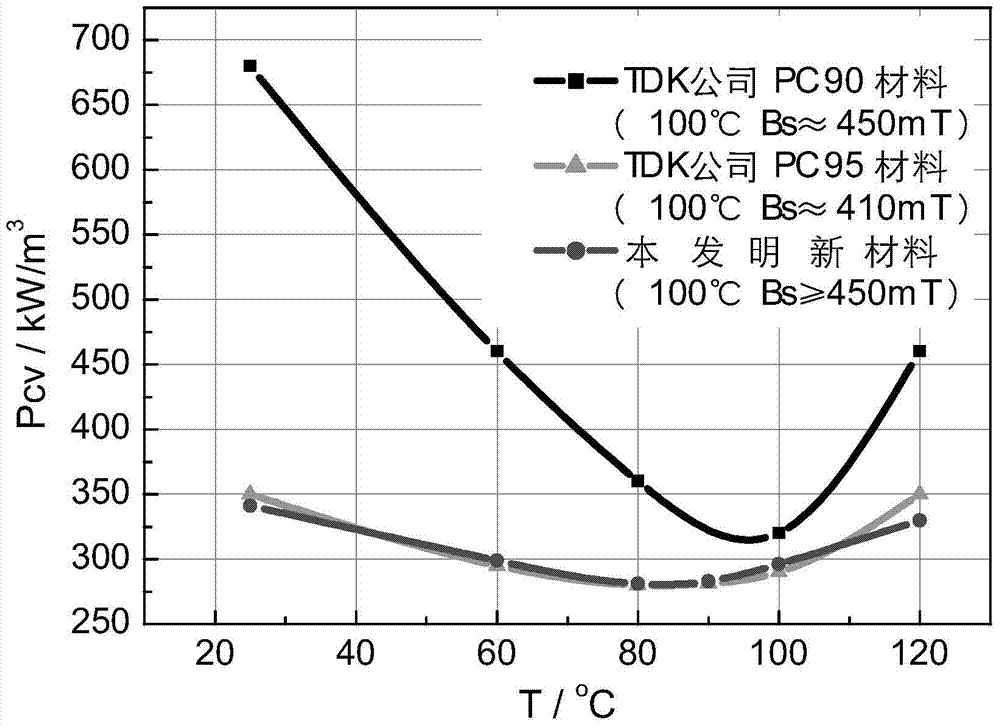

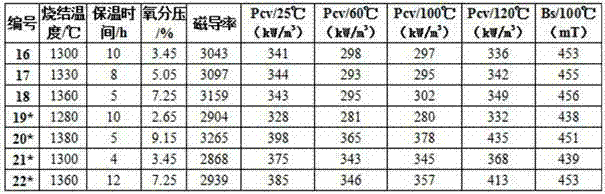

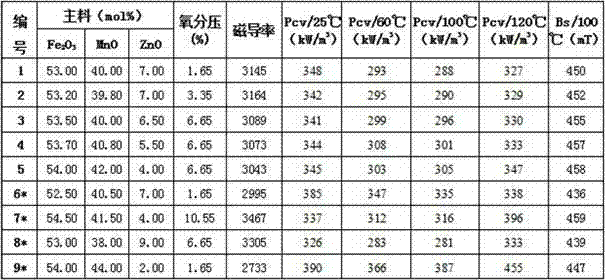

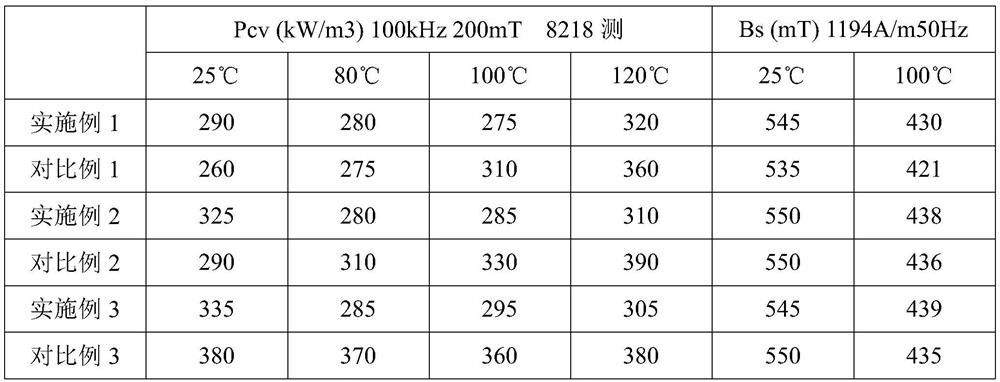

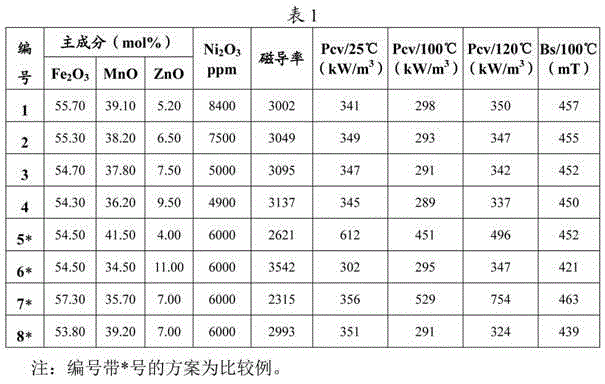

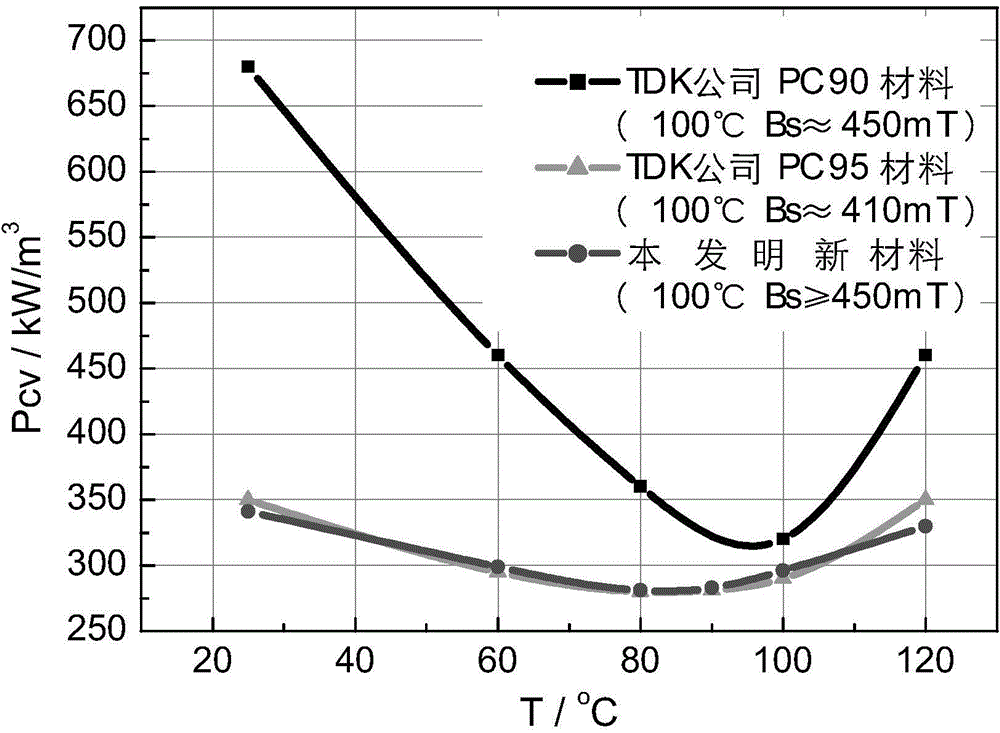

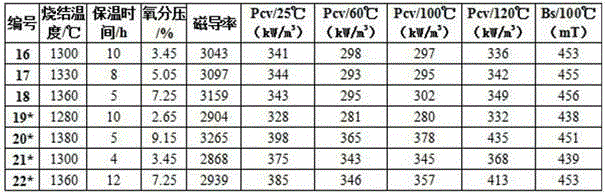

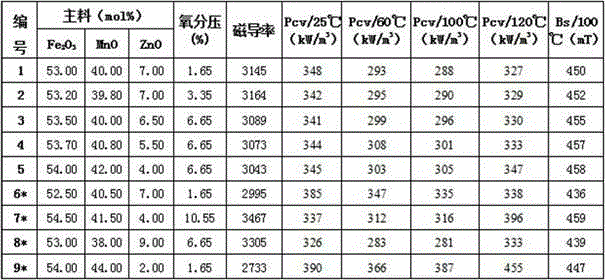

The invention provides a Ni-free MnZn ferrite magnetic core with double characteristics and a manufacture method thereof, wherein the double characteristics mean high temperature and high Bs, and wide temperature and low loss. The ferrite magnetic core comprises main components and auxiliary components. The main components comprise: 53 mol%-54 mol% of Fe2O3, 39 mol%-42 mol% of MnO and 4 mol%-7 mol% of ZnO; and the auxiliary components comprise: Co2O3 or CoO or Co3O4 as a first auxiliary component, SiO2 and CaCO3 as a second auxiliary, and a third auxiliary component which is one or more selected from MoO3, TiO2, SnO2, Nb2O5, V2O5, Sm2O3 and ZrO2. The provided MnZn ferrite magnetic core with double characteristics has unit volume loss Pcv (100kHz, 200mT) less than 350 kW / m<3> at the temperature of 25 DEG C to 120 DEG C, lowest loss of 300 kW / m<3> at the temperature of about 90 DEG C, and saturation magnetic flux density up to 450 mT at the temperature of 100 DEG C.

Owner:江门安磁电子有限公司

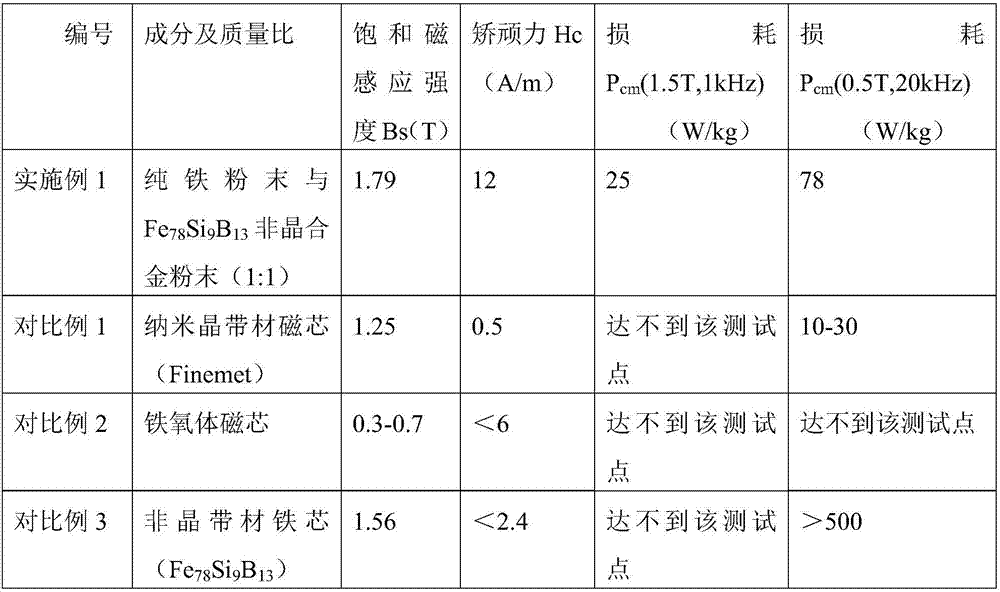

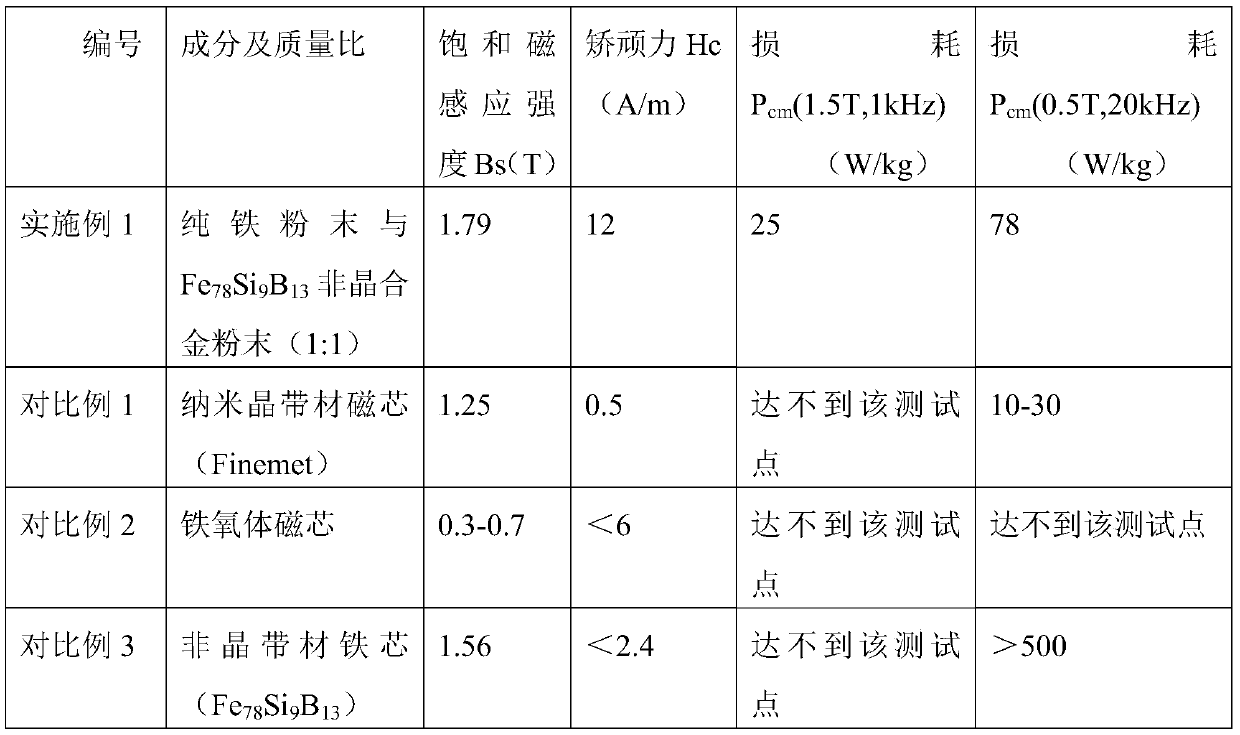

High-saturation flux density composite magnetic powder, magnetic core and preparation methods thereof

ActiveCN107240471AHigh Bs valueReduce loss valueTransportation and packagingMetal-working apparatusIron powderMicrometer

The invention relates to high-saturation flux density composite magnetic powder. The high-saturation flux density composite magnetic powder is prepared from powder A and powder B, wherein the proportion is as follows: 5-95wt% of powder A and 5-95wt% of powder B, the powder A is at least one of iron silicon powder, pure iron powder, iron silicon aluminum power, iron nickel powder, iron nickel molybdenum powder and iron cobalt alloy powder, the powder B is at least one of iron-based amorphous alloy powder, iron-based nanocrystal alloy powder, iron-nickel-based amorphous alloy powder, iron-cobalt-based amorphous alloy powder and iron-cobalt-based nanocrystal alloy powder, and the grain sizes of the powder A and the powder B are 8-200 micrometers. A magnetic core prepared by employing the composite magnetic powder has the characteristics of high Bs, low loss, low cost and the like and is suitable for mass production, the Bs value is 1.71T or above, the loss is not higher than 50W / kg under 1.5T and 1,000Hz, and the magnetic core particularly and suitably works in a medium- and low-frequency range (50Hz-10kHz).

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

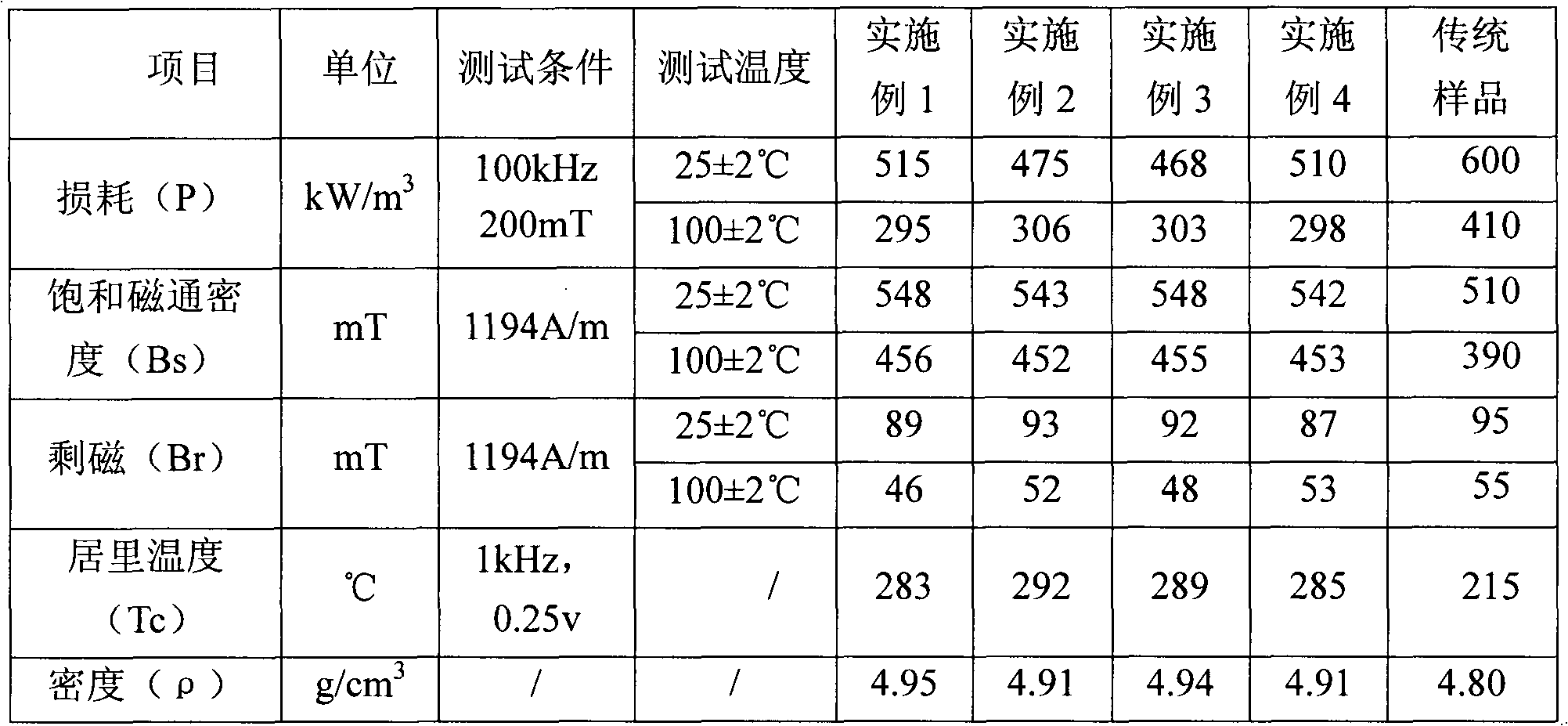

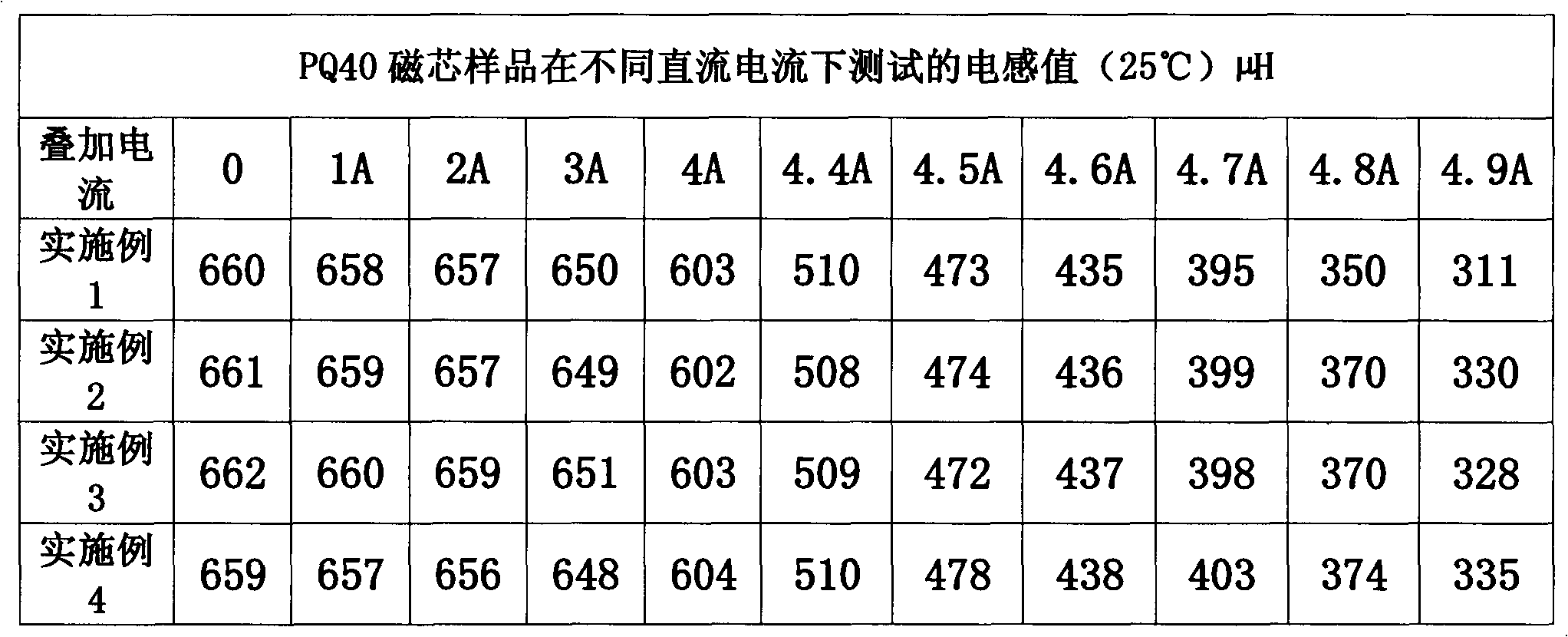

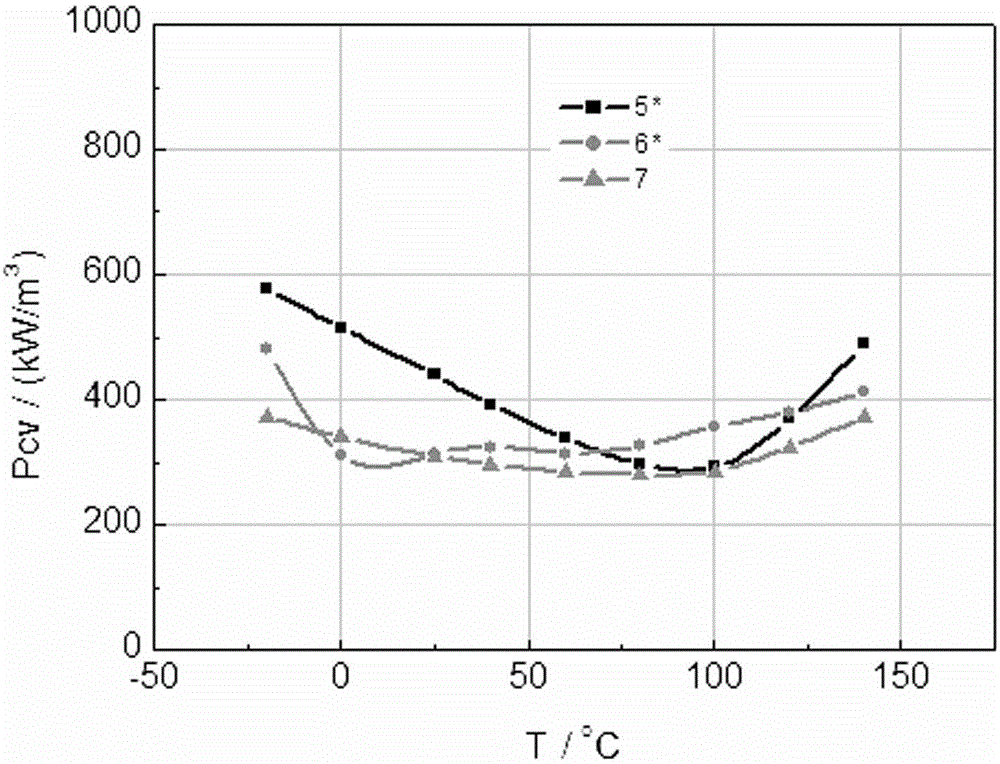

High-saturation magnetic flux, high-direct current superposition and low-loss soft magnetic material and preparation method thereof

The invention relates to a high-saturation magnetic flux, high-direct current superposition and low-loss soft magnetic material and a preparation method thereof. The soft magnetic material comprises the following main components: 53.5 to 55 molar percent of Fe2O3, 4 to 9.5 molar percent of ZnO, and the balance of MnO; and based on the total weight of the main components, the soft magnetic material comprises the following auxiliary components: 0.01 to 0.05 weight percent of WO3, 0.005 to 0.03 weight percent of NiO, and 0.02 to 0.06 weight percent of ZrO2. The soft magnetic material has higher saturation magnetic flux density Bs in a wide temperature range and a larger difference between the saturation magnetic flux density Bs of the soft magnetic material and residual magnetic flux density Br exists, power consumption is greatly reduced in the wide temperature range particularly, the superposition performance is high, and Curie temperature is relatively high, so that a plurality of electromagnetic parameters are matched more optimally, and the soft magnetic material is particularly suitable for realizing the higher and more stable electrical inductance function on various occasions with large direct current superposition.

Owner:RUYUAN DONGYANGGUANG MAGNETIC MATERIAL

Low-angle-difference nanocrystalline magnetically soft alloy magnetic core for intelligent electric meter and preparation method thereof

ActiveCN105861959AExcellent soft magnetic propertiesImprove thermal stabilityTransformers/inductances magnetic coresMagnetic materialsAlloyInductor

The invention belongs to the field of magnetically soft alloy and particularly discloses a low-angle-difference nanocrystalline magnetically soft alloy magnetic core for an intelligent electric meter and a preparation method thereof. The molecular formula of the magnetic core is shown as follows: Fe100-a-b-c-d-eSiaBbMcCudNbeM'f, wherein a, b, c, d, e and f are atomic percents, 8<=a<=14, 2<=b<=10, 0.8<=c<=3, 1<=d<=4, 0.5<=e<=2, 0.02<=f<=0.5, the balance is Fe and unavoidable impurities, M is Al or Zn, and M' is one or more of Y, Gd, V, Mo, Mn, Ge, Er, Ga and Sn. The magnetic core which is prepared through a resultant magnetic field annealing treatment method and is excellent in soft magnetic property is further provided, and the requirement for high-precision measurement with a low-angle-difference mutual inductor for the intelligent electric meter is met.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD

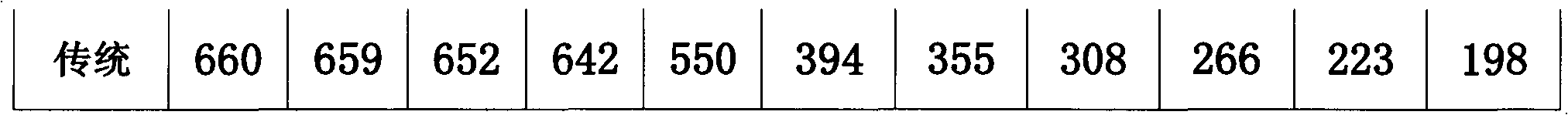

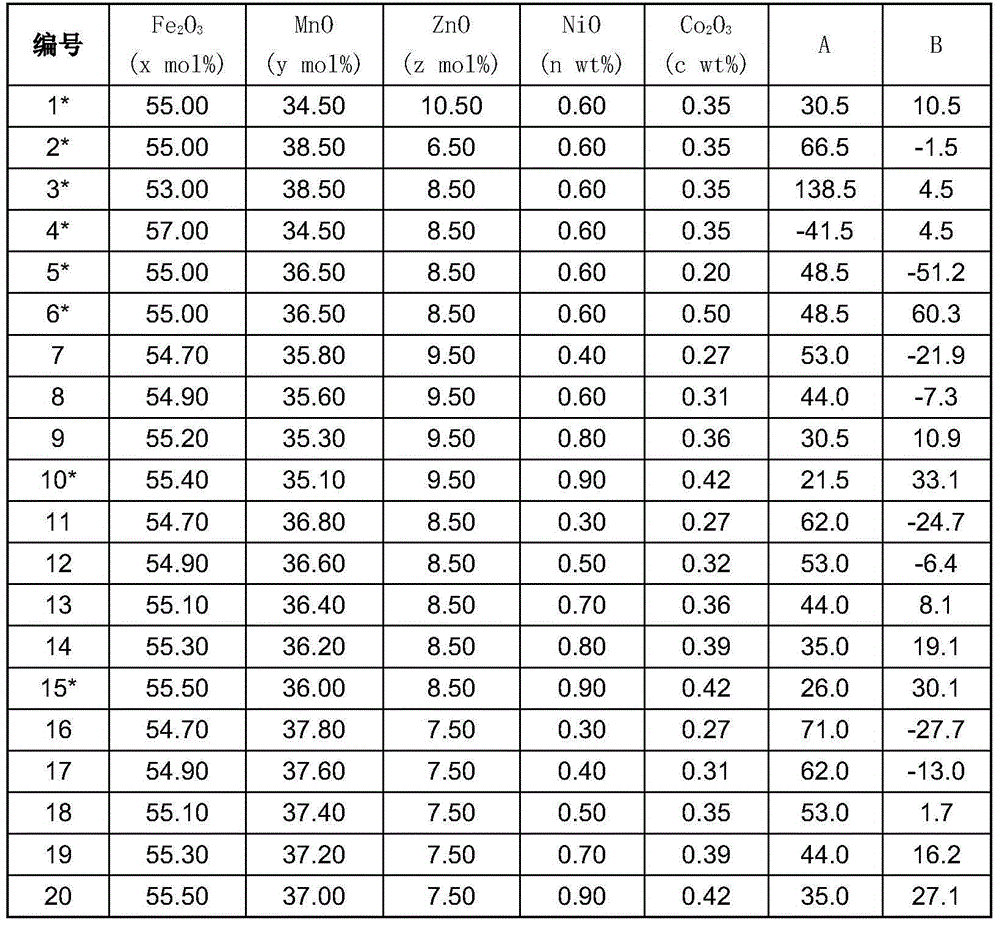

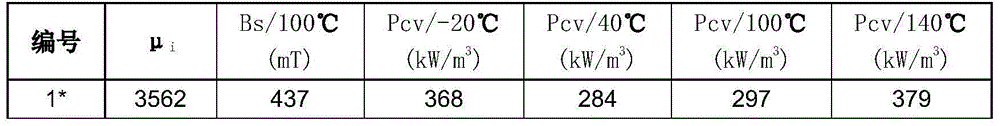

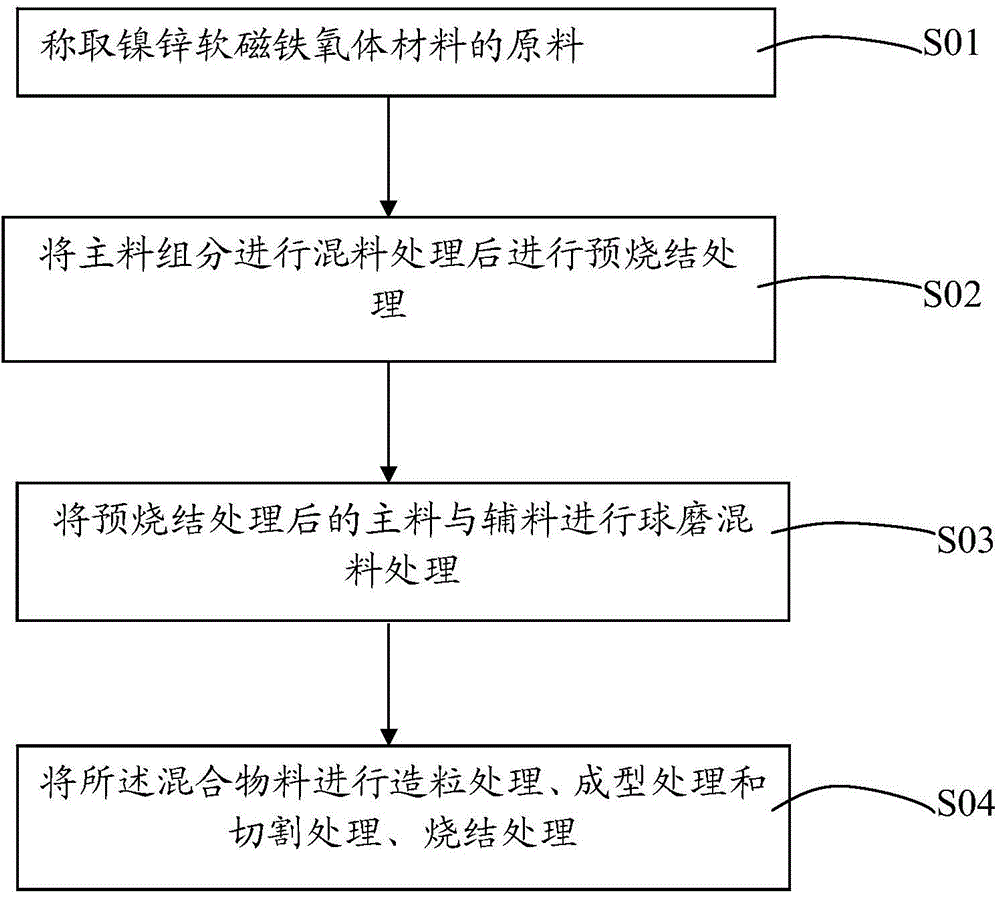

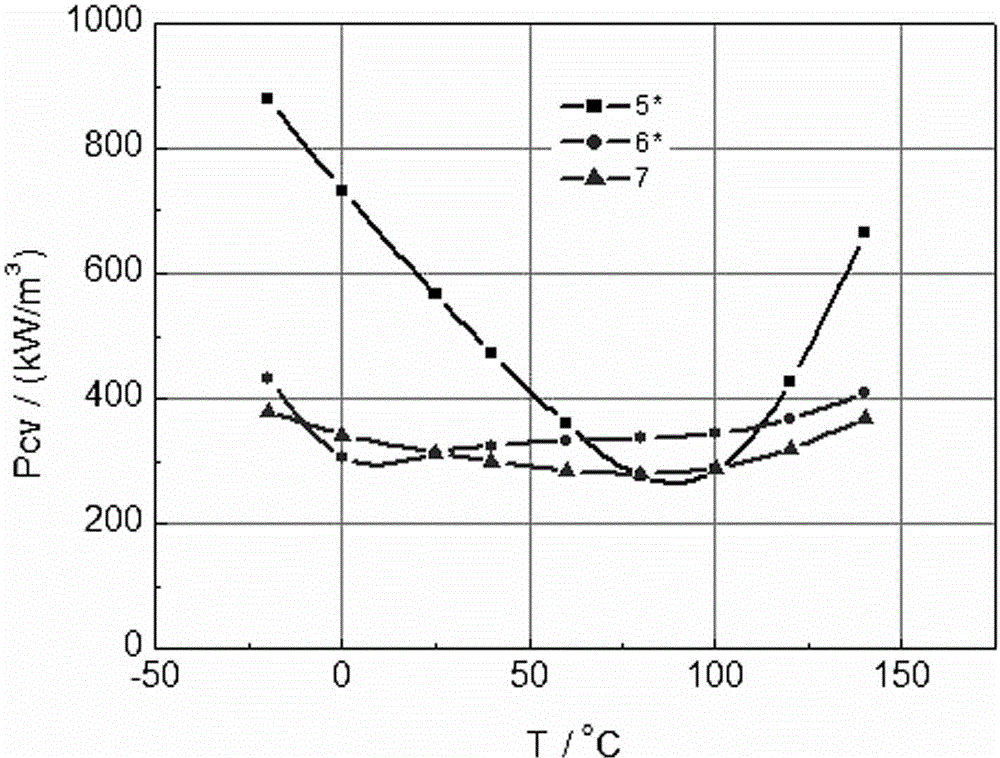

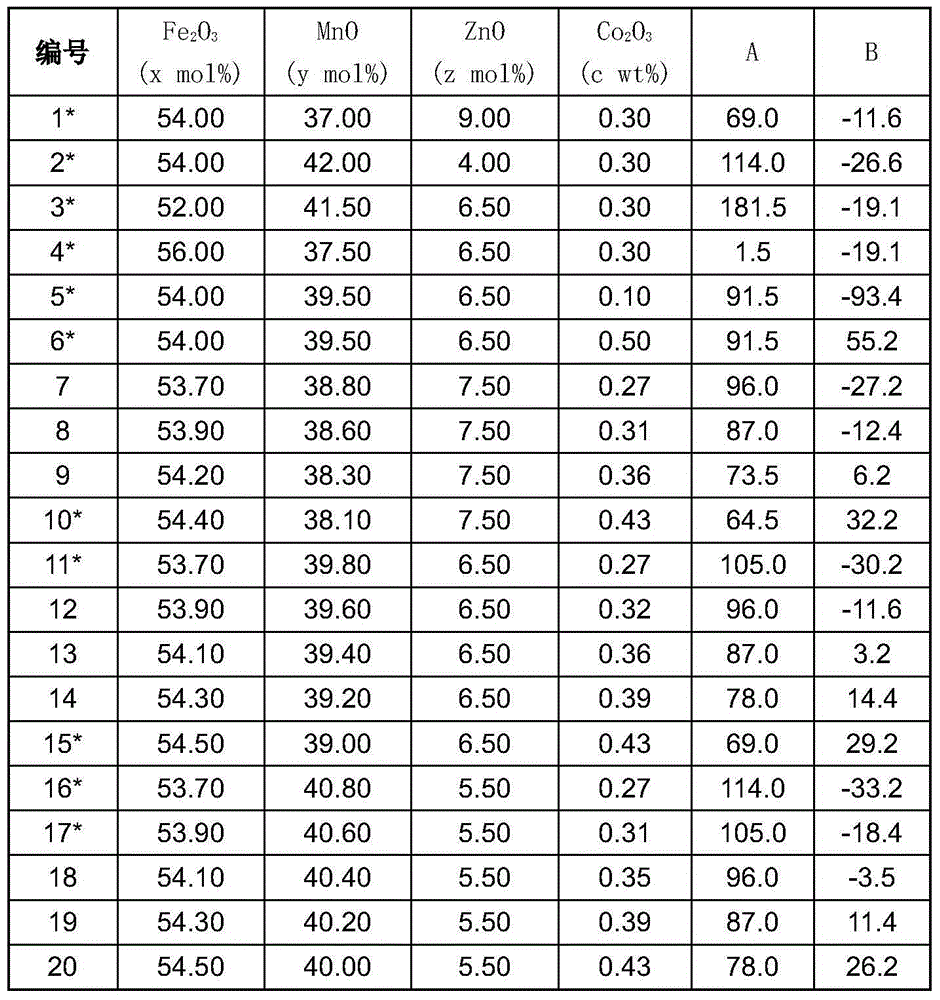

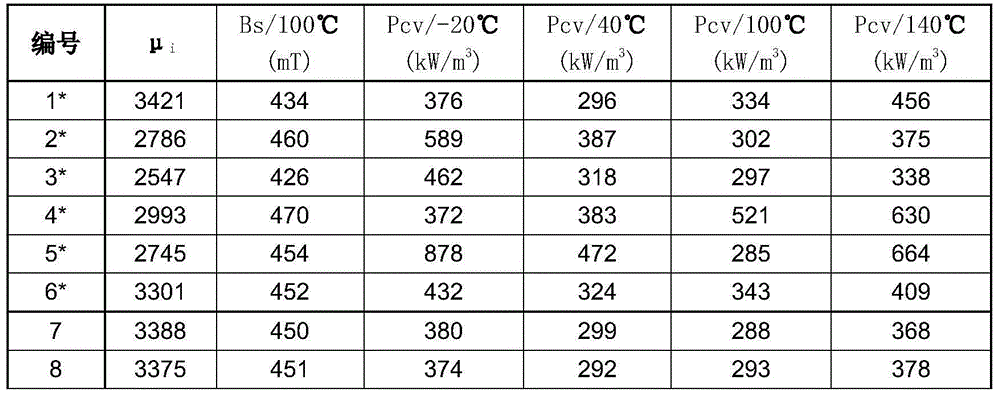

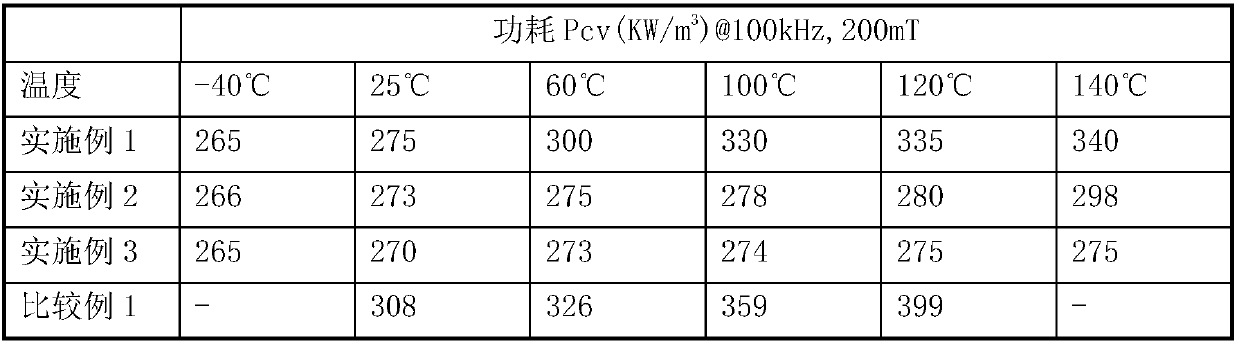

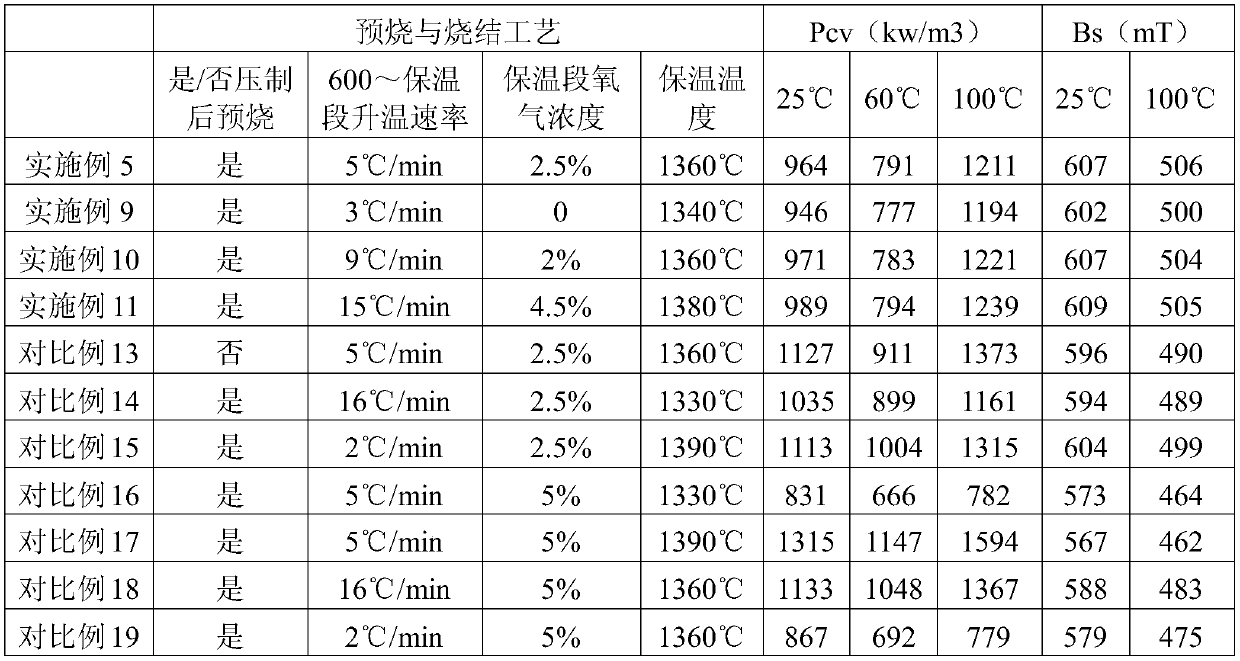

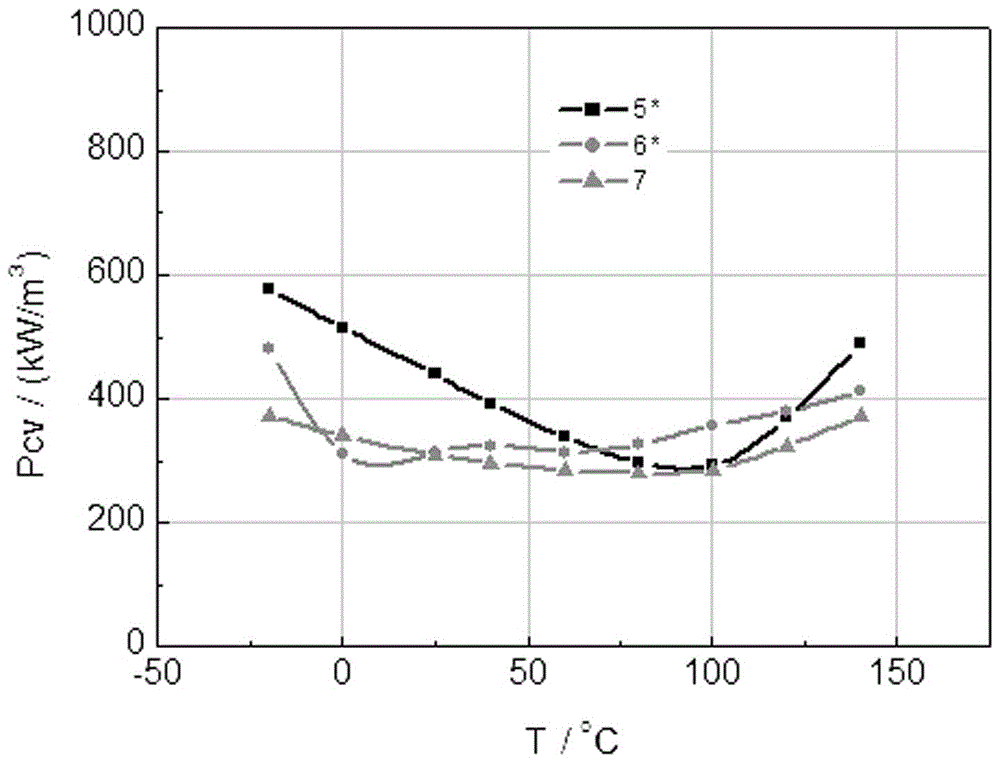

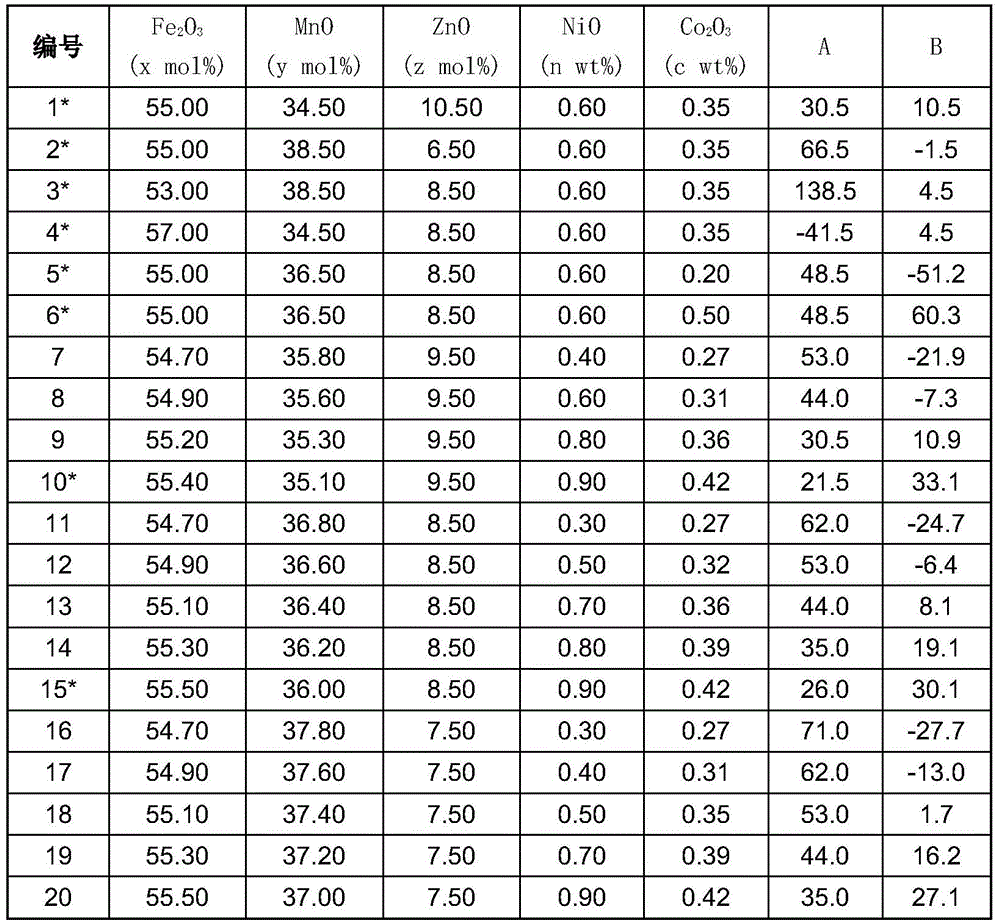

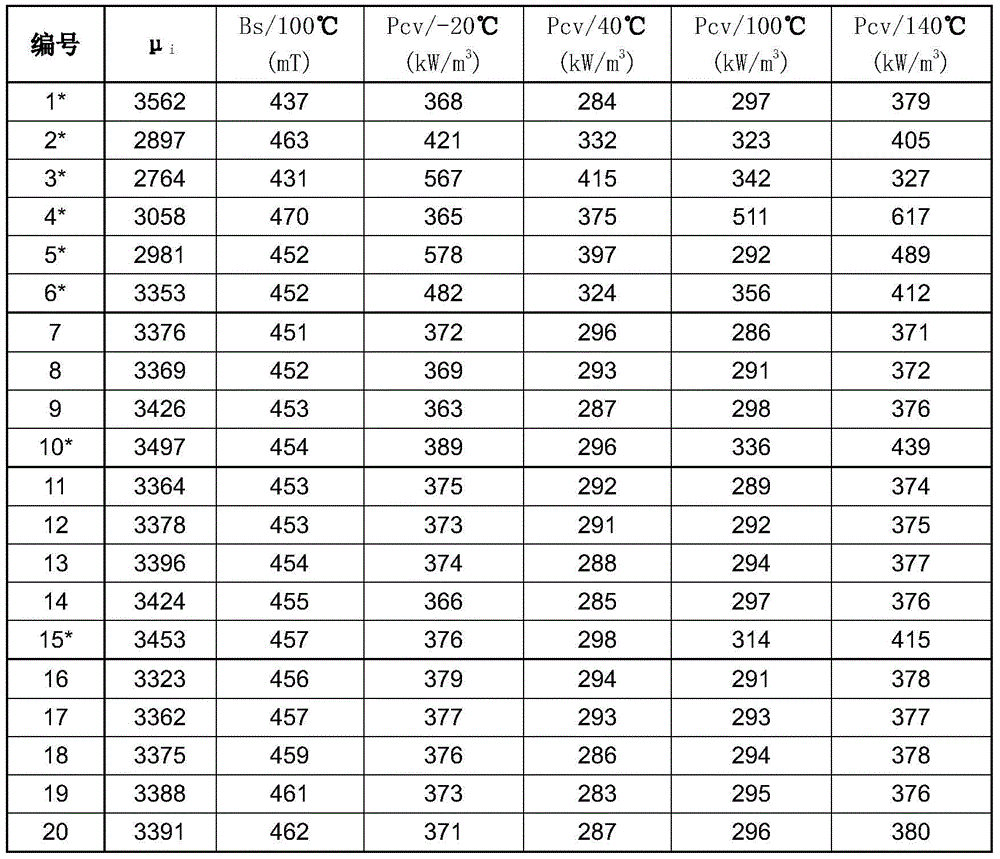

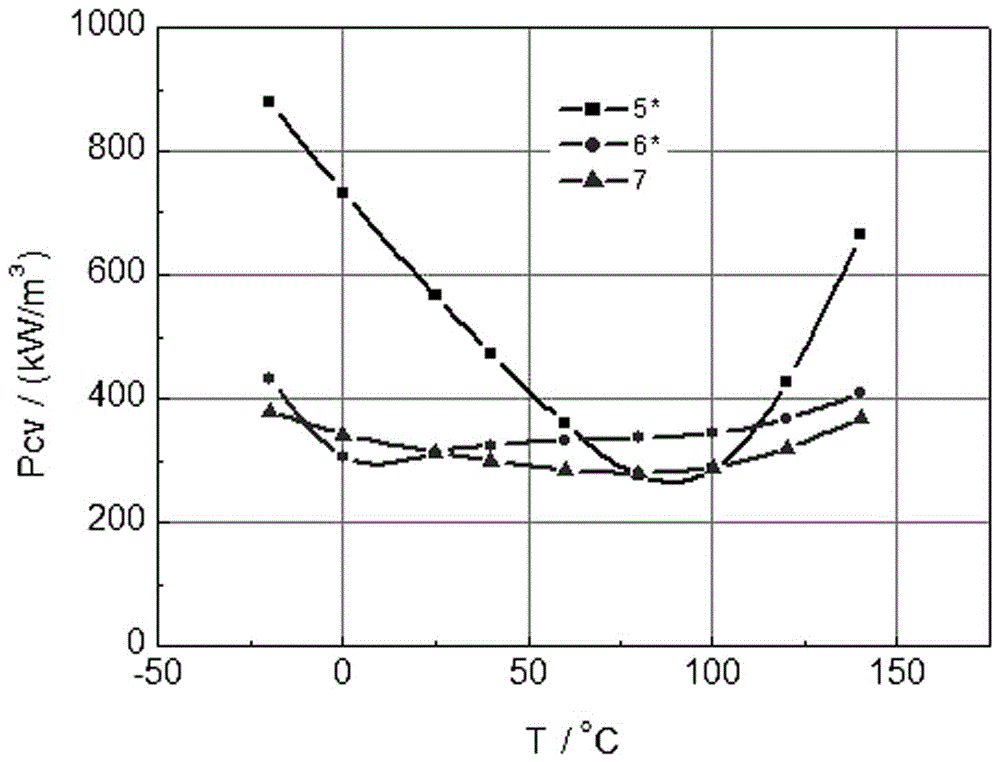

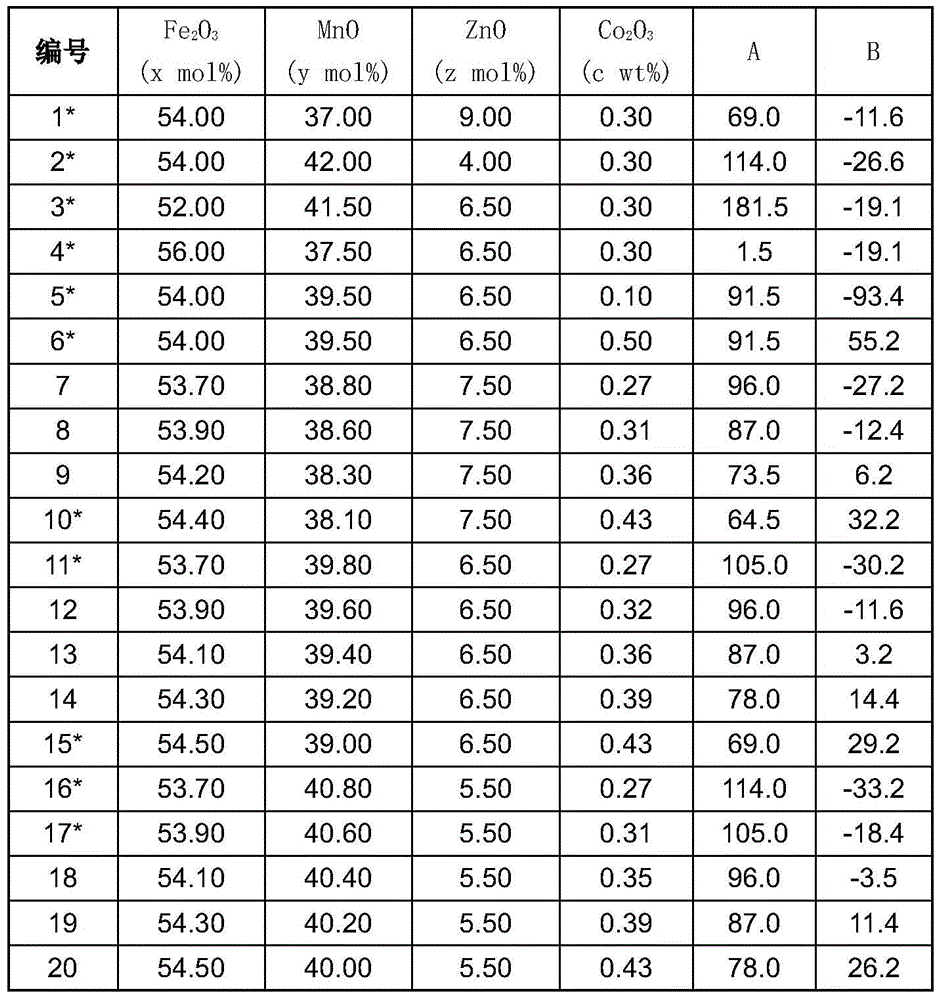

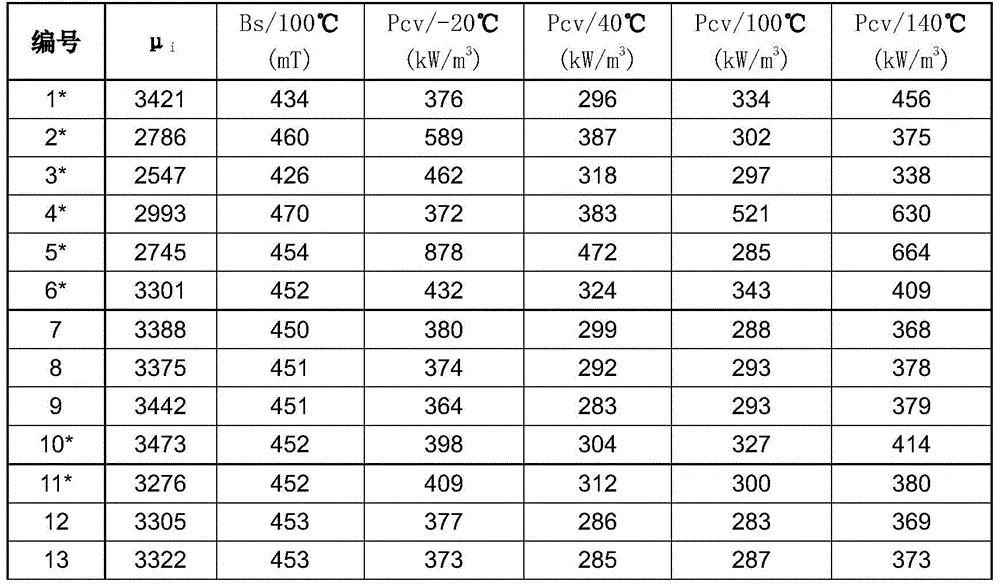

Low-loss manganese zinc ferrite material for temperature of 20 DEG C below zero to 140 DEG C and manufacturing method thereof

The invention provides a low-loss manganese zinc ferrite material for temperature of 20 DEG C below zero to 140 DEG C and a manufacturing method thereof. The ferrite material comprises main components and auxiliary components, wherein the main components refer to x mol% of Fe2O3, y mol% of MnO and z mol% of ZnO; the auxiliary components comprise c wt% of Co2O3 and n wt% of NiO based on the total weight of main components; the ratios of the components are that x is equal to 54.5-55.5, z is equal to 7.5-9.5, y is equal to 100-x-z, c is equal to 0.25-0.45 and n is equal to 0.3-0.9; A being 2600-45x-9z is more than or equal to 30 and less than or equal to 80; and B being 150-3x-3y+371c-1.6n is more than or equal to -30 and less than or equal to 30. The manganese zinc ferrite material is prepared by the process steps of batching, mixing, pre-sintering, performing secondary grinding, granulating, molding and sintering.

Owner:江门安磁电子有限公司

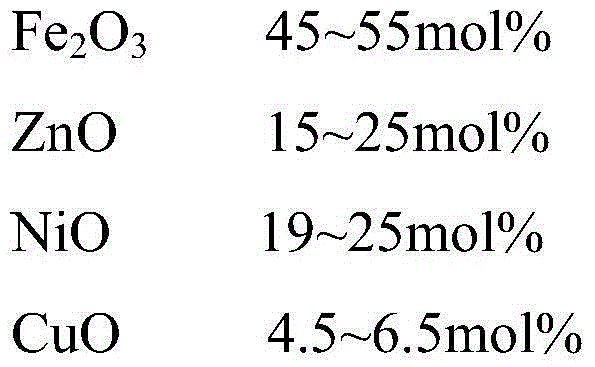

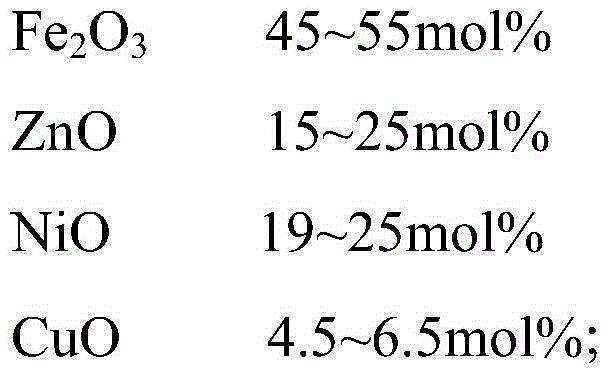

Ni-Zn soft-magnetic ferrite material, Ni-Zn ferrite, preparation method thereof and electrical inductance

InactiveCN105985103AExcellent strength and thermal shock resistanceGood thermal shock resistanceInorganic material magnetismNickelMagnet

The invention discloses a nickel-zinc soft ferrite material, a NiZn ferrite, a preparation method thereof and an inductor. The nickel-zinc soft magnetic ferrite material includes the main material of the following mole percentage components: Fe 2 o 3 45~55mol%, ZnO 15~25mol%, NiO 19~25mol%, CuO 4.5~6.5mol%; including the following components and auxiliary materials in weight percentage: Bi 2 o 3 0~0.8wt%, Co 2 o 3 0~0.5wt%, V 2 o 5 0-0.05wt%. The NiZn ferrite of the present invention is prepared by using the nickel-zinc soft magnetic ferrite material of the present invention, and the inductor of the present invention contains the NiZn ferrite of the present invention. The nickel-zinc soft magnetic ferrite material, NiZn ferrite and inductor of the invention have excellent strength, thermal shock resistance and high Bs characteristics.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

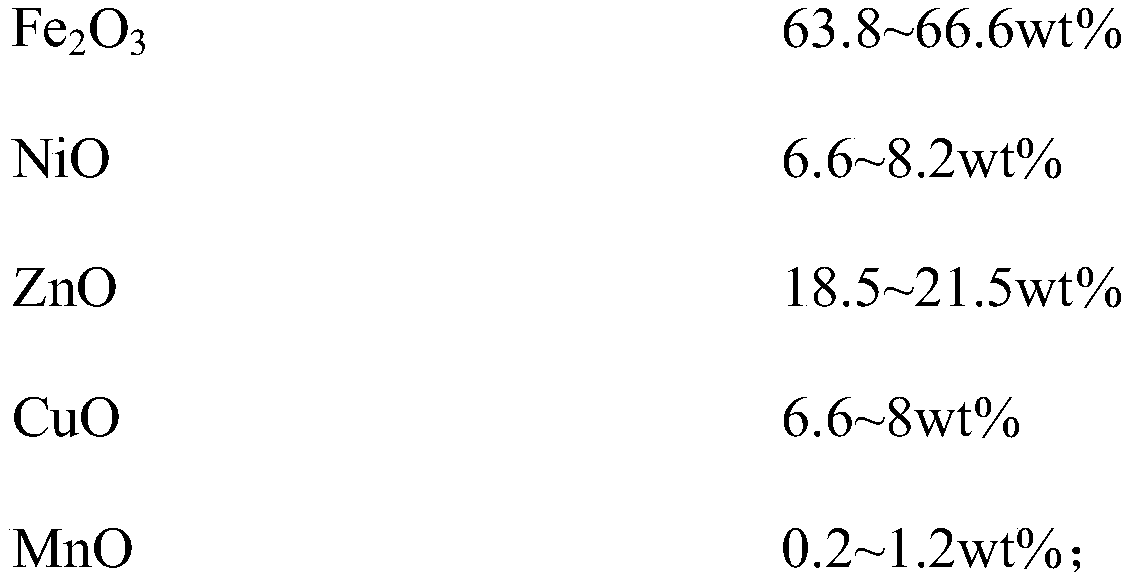

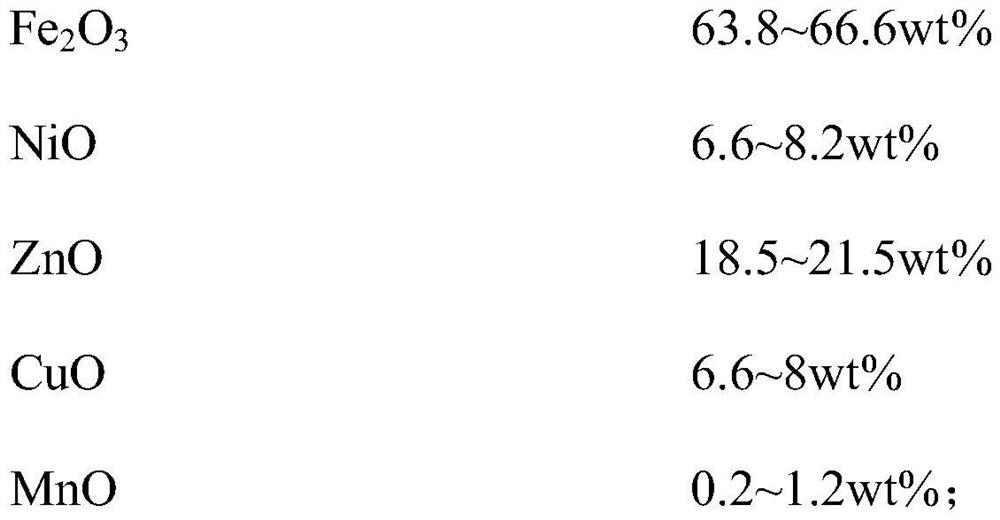

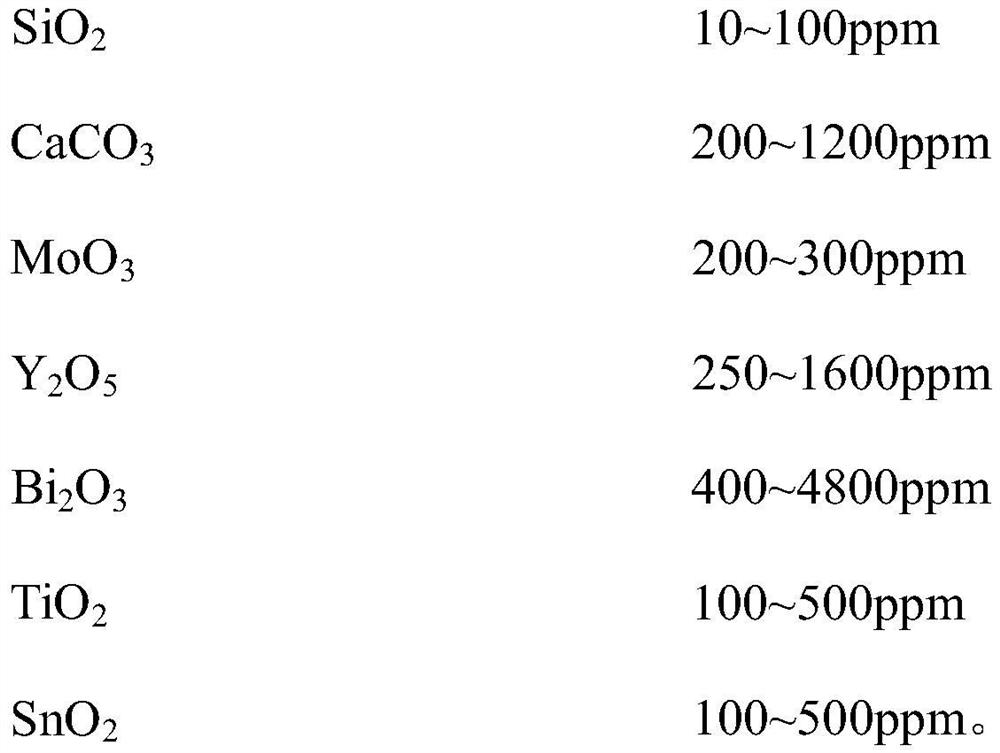

Nickel-zinc ferrite material, and preparation method and use thereof

ActiveCN110357610AHigh strengthReduce high temperature impact resistanceTrace elementNickel-zinc ferrite

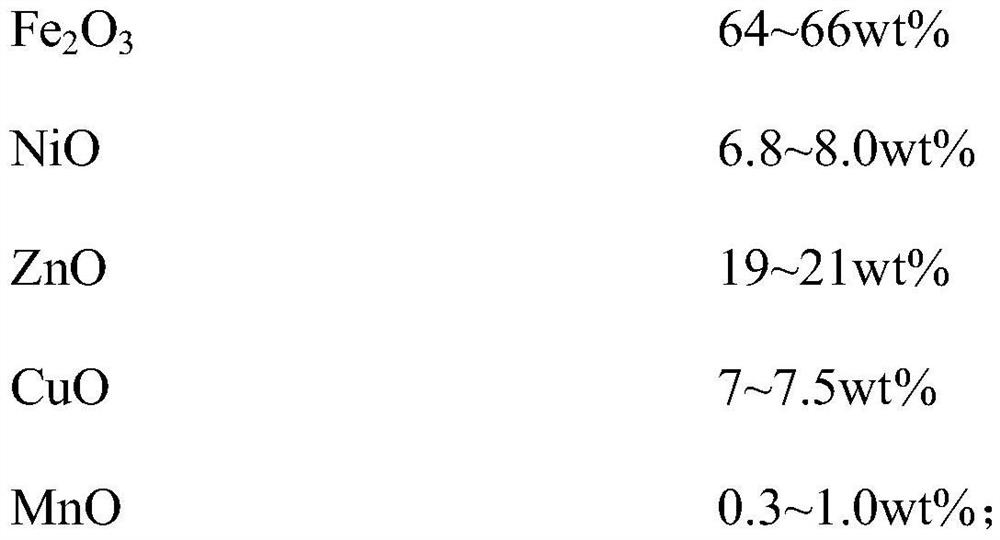

The invention discloses a nickel-zinc ferrite material, and a preparation method and a use thereof. The nickel-zinc ferrite material comprises a main component and an additive, and the main componentcomprises Fe2O3, ZnO, NiO, CuO and MnO; and the additive comprises a group IVA oxide, a group IIA oxide, a group VIB oxide, a group IIIB oxide, a group VA oxide and a group IVB oxide. Formula development and trace element modification in the invention overcome the contradiction that improvement of the strength of a magnetic core reduces the high temperature shock resistance or improvement of the thermal shock resistance lowers the strength of the magnetic core, and the high-performance soft ferrite material with a high magnetic permeability, a high Bs value, a high strength and a high thermalshock resistance and for SMD power inductors is developed.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

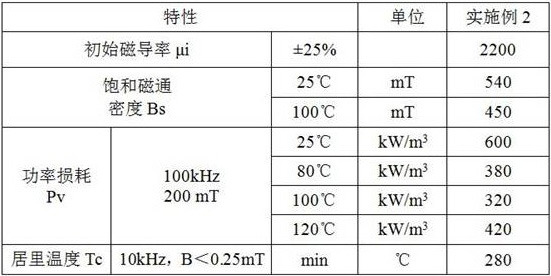

Soft magnetic ferrite material with high Bs value and low power loss and preparation method of magnetic core of soft magnetic ferrite material

ActiveCN108640670AReduce power lossHigh Bs valueInorganic material magnetismPorosityInitial permeability

The invention provides a soft magnetic ferrite material with a high Bs value and low power loss and a preparation method of a magnetic core of the soft magnetic ferrite material. A main formula and effective doping are preferably selected, the soft magnetic ferrite material with the high Bs value and the low power loss is developed, the final product has a crystal grain size of 3-4 [mu]m, the initial permeability ui reaches 2200 or more, the power loss at temperature of 80-120 DEG C, 100 kHz and a Bs value of 200 mT is 380-420 kW / m<3>, and the Bs value at temperature of 100 DEG C is 450 mT ormore; a multi-stage balanced atmosphere sintering method is adopted, the density, crystal grain size, porosity and distribution in and among crystal grains of the ferrite material are controlled, so that a microstructure of soft magnetic ferrite is more effectively controlled to ensure main characteristic parameters of the material to reach harmonious unification; and the final product has high quality, and the production costs are reduced by 20% or more.

Owner:湖北华磁电子科技有限公司

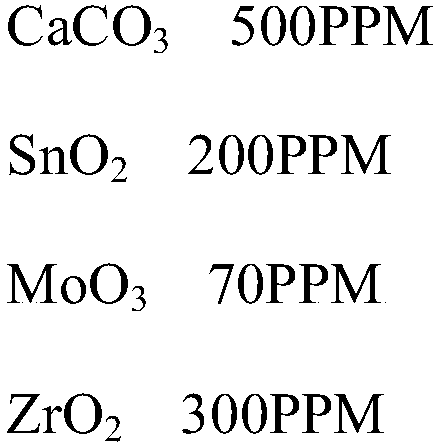

Ni-free manganese zinc ferrite material applied to (-20)-140 DEG C and manufacturing method thereof

The invention provides a Ni-free manganese zinc ferrite material applied to (-20)-140 DEG C and a manufacturing method thereof. The ferrite material comprises principal components and auxiliary component, wherein the principal components include Fe2O3 (x mol %), MnO (y mol %) and ZnO (z mol %), the auxiliary component is Co2O3 with a weight accounting for c wt % of the total weight of the principal components, the proportion of each component is as follows: x = 53.5-54.5, z = 5.5-7.5, y = 100-x-z, c = 0.25-0.45, and the components have the following relations: 70<=A=2580-45x-9z<=100, and -30<=B=150-3x-3y+371c<=30. The manganese zinc ferrite material is prepared through the process steps of preparing, mixing, presintering, secondary grinding, granulating, molding, sintering, and the like.

Owner:江门安磁电子有限公司

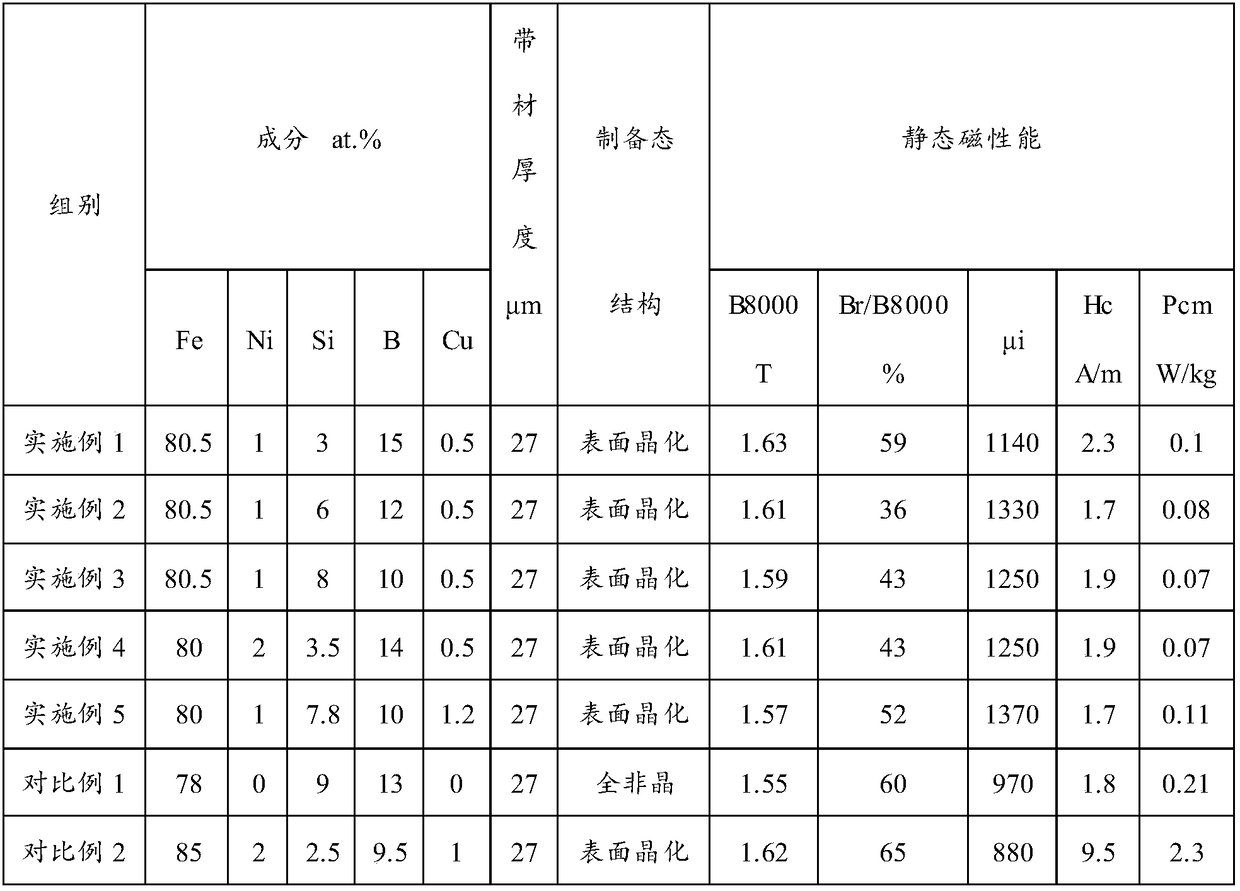

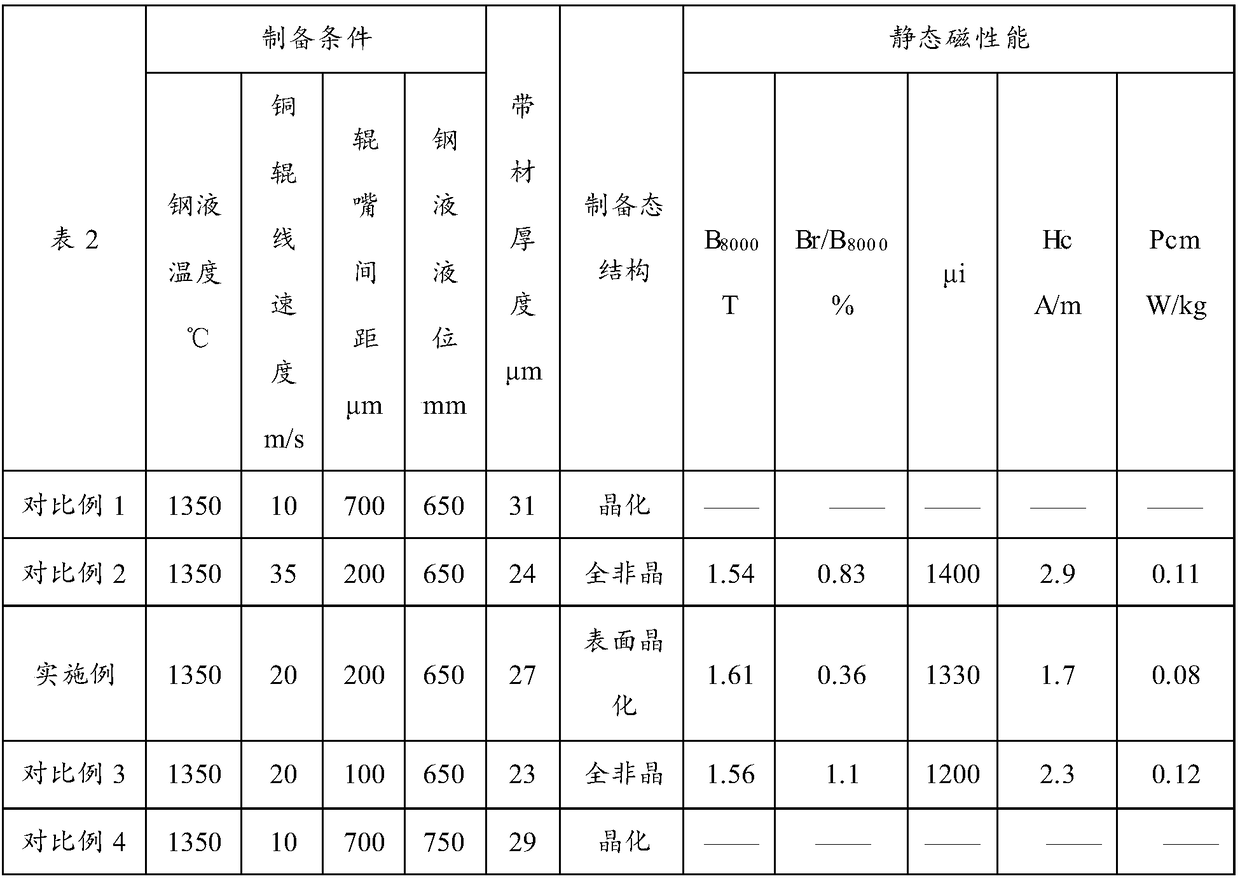

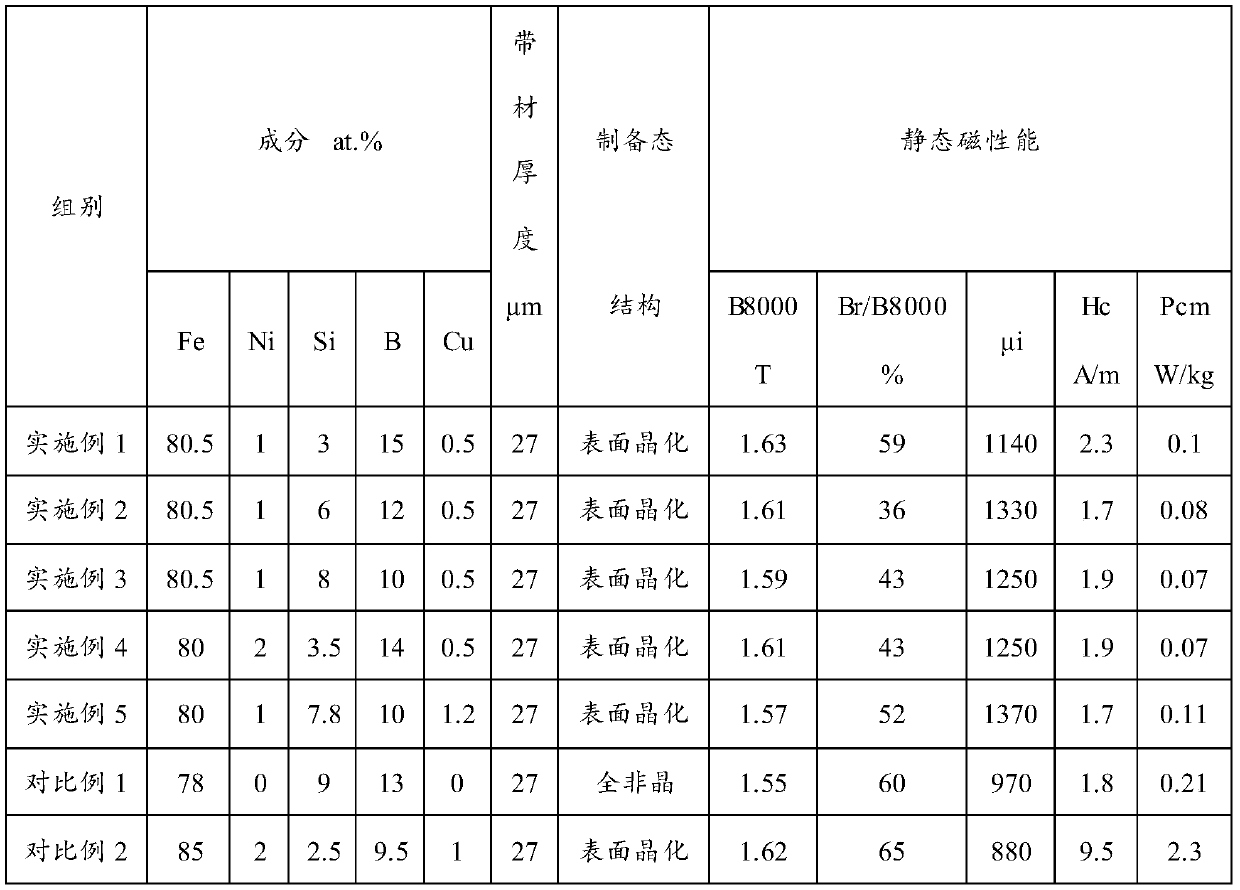

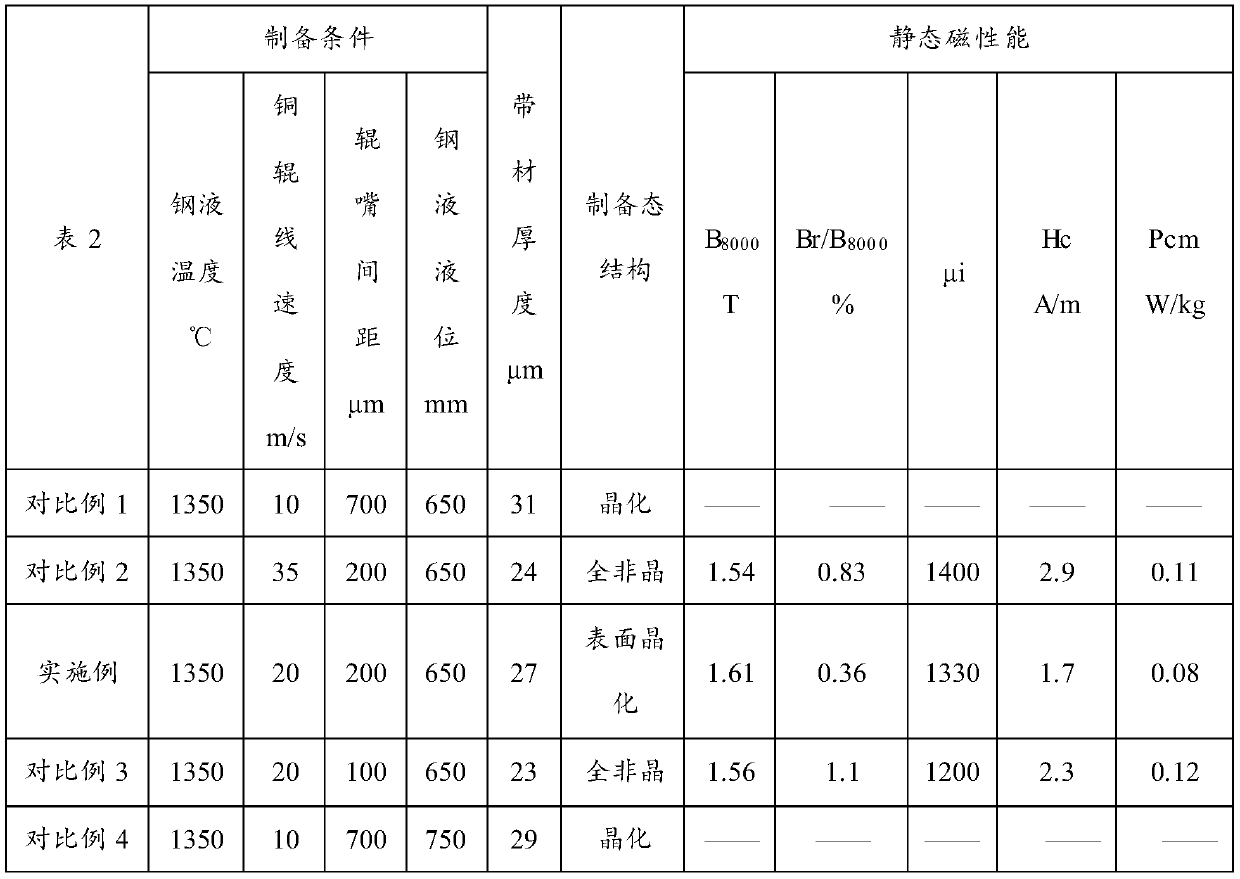

Preparation method of Fe-based amorphous alloy magnetic core and Fe-based amorphous alloy

The invention provides a preparation method of a Fe-based amorphous alloy magnetic core. The preparation method of the Fe-based amorphous alloy magnetic core comprises the following steps of A) preparing materials according to components of a Fe-based amorphous alloy shown in a formula (I), and smelting the prepared raw materials into molten steel; B) cooling the molten steel by using a single-roller rapid quenching method to obtain a Fe-based amorphous alloy thin strip; C) winding the Fe-based amorphous alloy thin strip into a ring so as to obtain a Fe-based amorphous alloy thin strip closedmagnetic core; and D) carrying out heat treatment on the Fe-based amorphous alloy thin strip closed magnetic core so as to obtain the Fe-based amorphous alloy thin strip magnetic core. According to the preparation method of the Fe-based amorphous alloy magnetic core, on the basis of using a surface crystallization method to prepare a permanent permeability Fe-based amorphous alloy, the Bs of the Fe-based amorphous alloy is increased by adjusting alloy components and preparation process parameters so that the Bs of the Fe-based amorphous alloy is increased, and the permanent permeability performance within a wider magnetic field range is realized.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

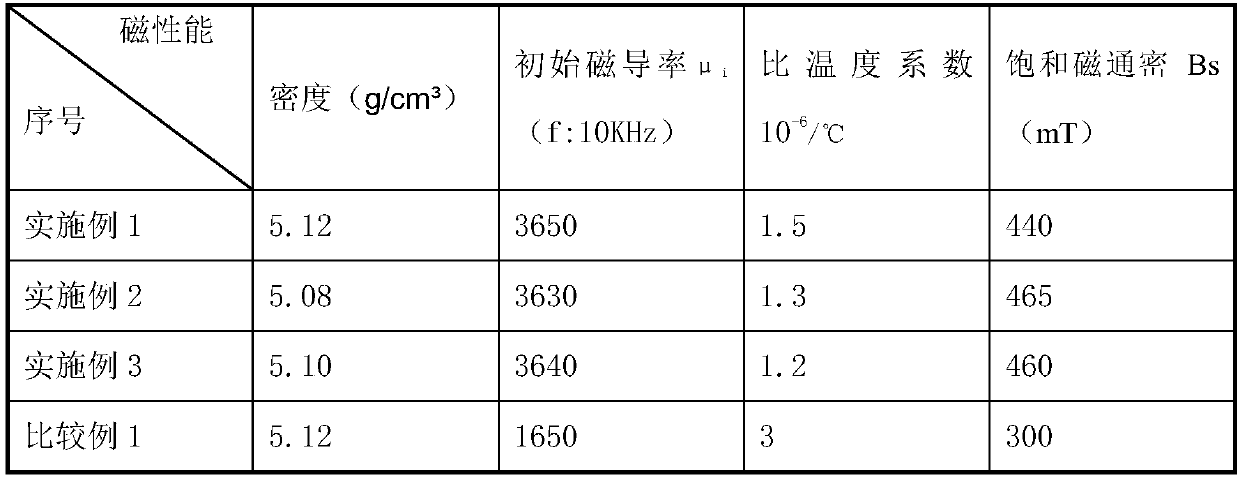

Preparation method of MnZn ferrite material with wide temperature range, low temperature coefficient and low power consumption

InactiveCN109678483AHigh saturation magnetizationReduce internal stressInorganic material magnetismTemperature coefficientPower consumption

The invention aims at providing a preparation method of a MnZn ferrite material with wide temperature range, low temperature coefficient and low power consumption. The preparation method comprises thefollowing steps: preparing main ingredients, performing first sanding on the main ingredients, pre-sintering the main ingredients, performing second sanding on the pre-sintered main ingredients and performing granulation, wherein GeO2, Cu2O3 and / or Sm2O3 are doped in the first sanding; K2O and / or TiO2 are / is doped in second sanding. According to the preparation method, the MnZn ferrite material is prepared by adjusting the composition of the main formula and the impurity adding mode; for the MnZn ferrite material, the saturation flux density is greater than 440mT, the specific temperature coefficient within the range of -40 DEG C-140 DEG C is less than or equal to 1.5*10<-6> / DEG C, and the power consumption coefficient Pcv under 100kHz is below 340kW / m<3>.

Owner:NANTONG HUAXING MAGNETIC MATERIAL

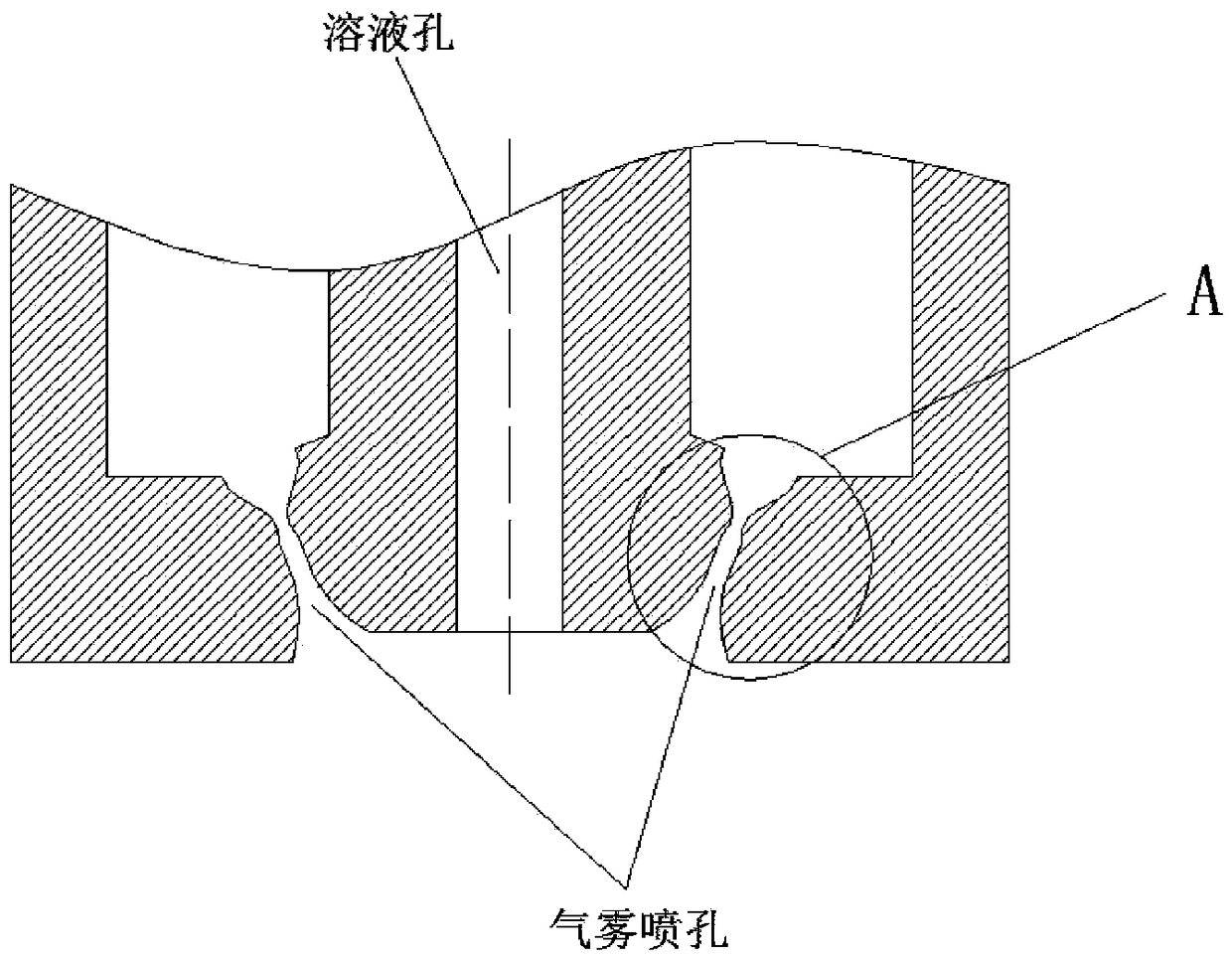

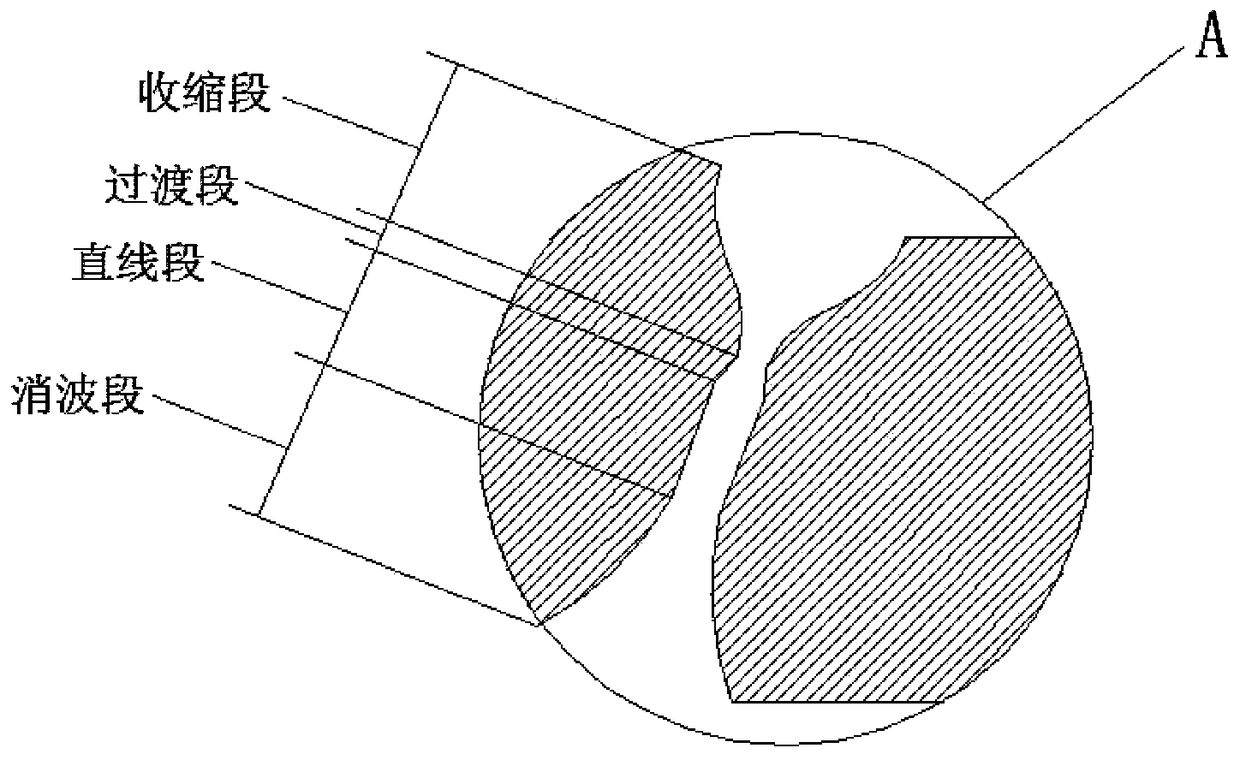

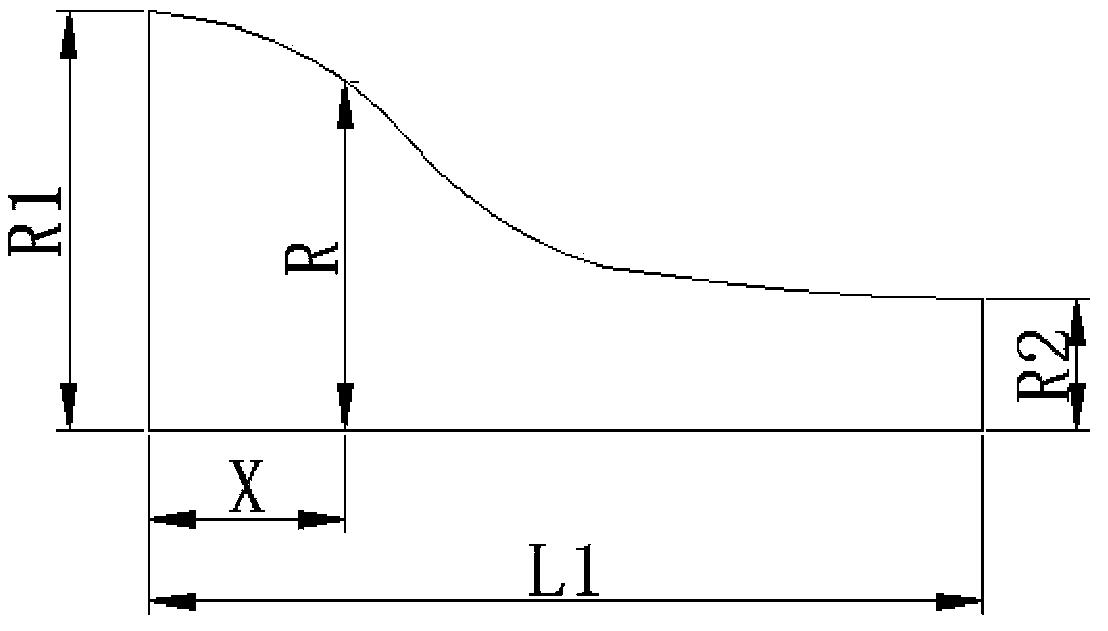

Preparing method for ultrathin metal powder for 3D printing and soft magnetic paster integrated component

InactiveCN108941585AControl permeabilityControl oxygen contentAdditive manufacturing apparatusTransportation and packagingManufacturing technologyThermal insulation

The invention discloses a preparing method for ultrathin metal powder for a 3D printing and soft magnetic paster integrated component and relates to the technical field of manufacturing of metal powder. The preparing method comprises the following steps: (1) dosing: dosing the raw materials including metal pure iron, metal chromium, metal nickel, metal cobalt and metal silicon according to a proportion; (2) smelting: placing the well-dosed raw materials in a smelting crucible to obtain solution ingredients; (3) high pressure gas atomizing: pouring the solution ingredients into a thermal insulation crucible, wherein the molten solution flows into a high pressure vacuum gas atomizing furnace by a small hole in the bottom of the thermal insulation crucible and is subjected to impact atomizingof high pressure nitrogen gas, so as to prepare the metal powder with a particle size of 10-100 micrometers; and (4) screening and annealing: grading the metal powder according to the particle size by a spin vibration sieve, and then annealing the graded metal powder to obtain a powder material. The preparing method has the advantages of improving the performances of the metal powder and controlling the parameters of the metal powder according to needs.

Owner:绵阳西磁科技有限公司

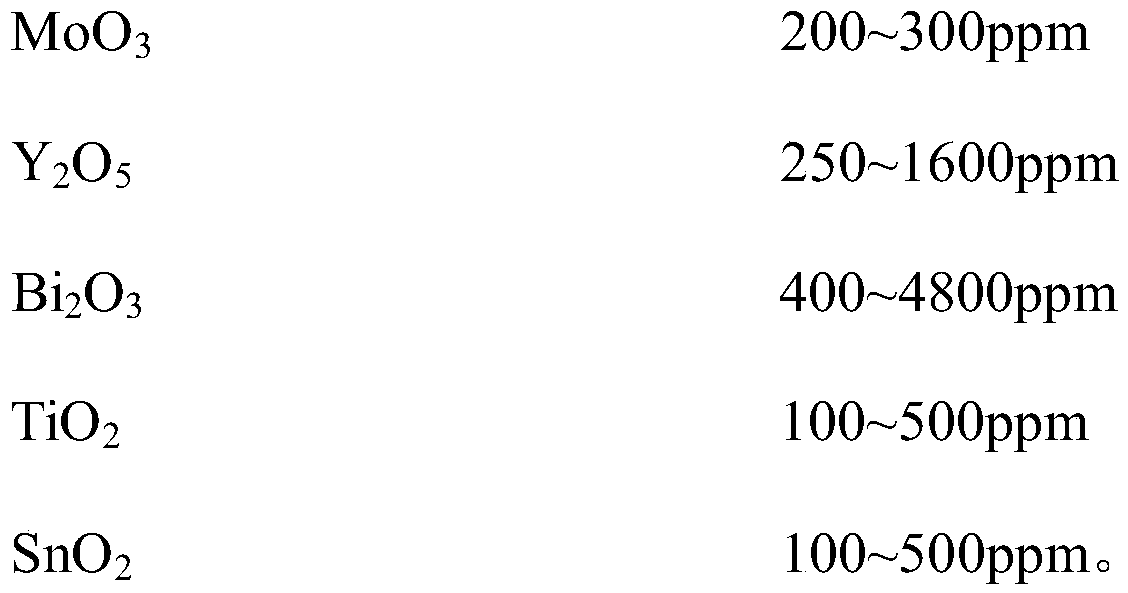

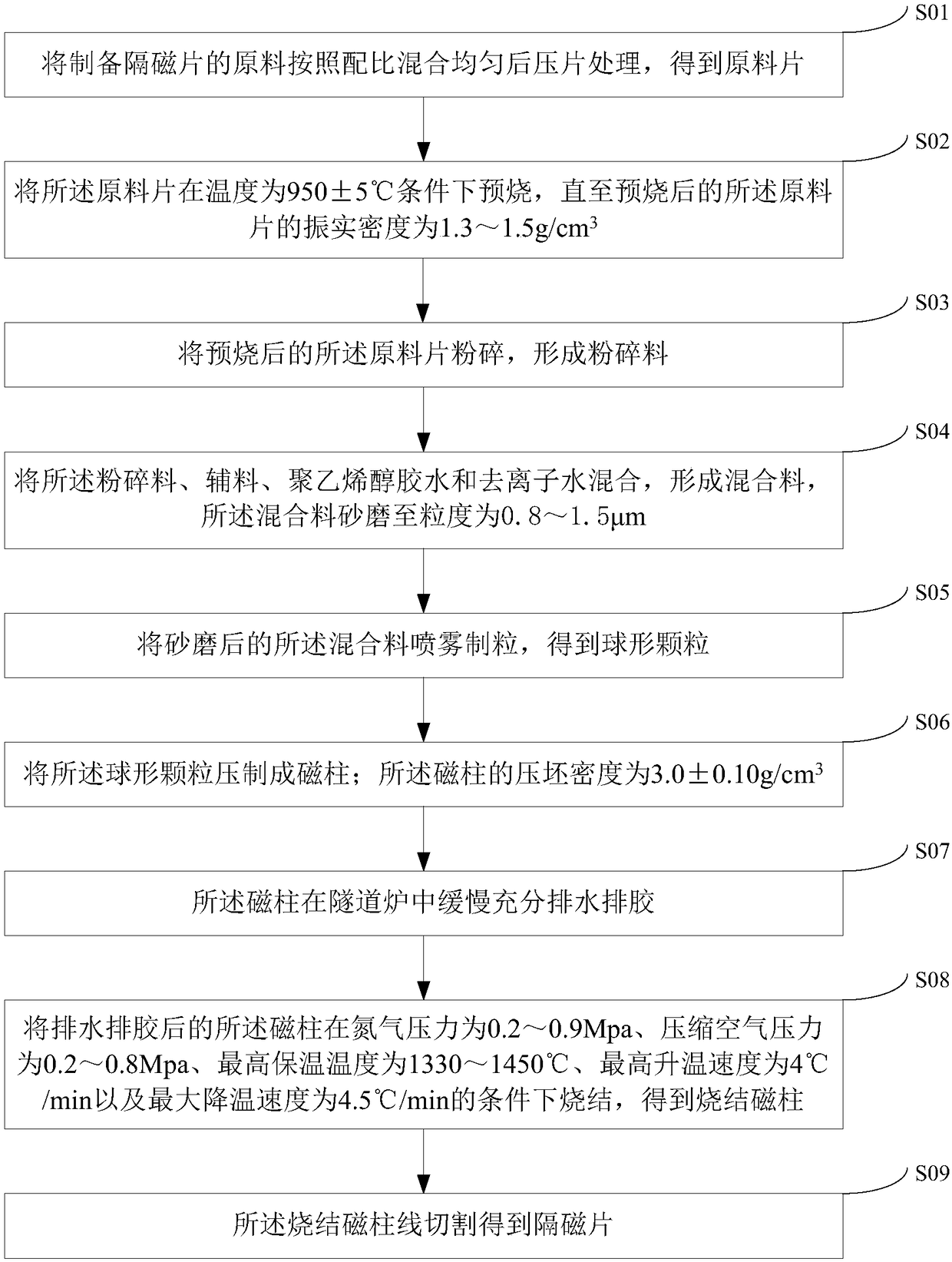

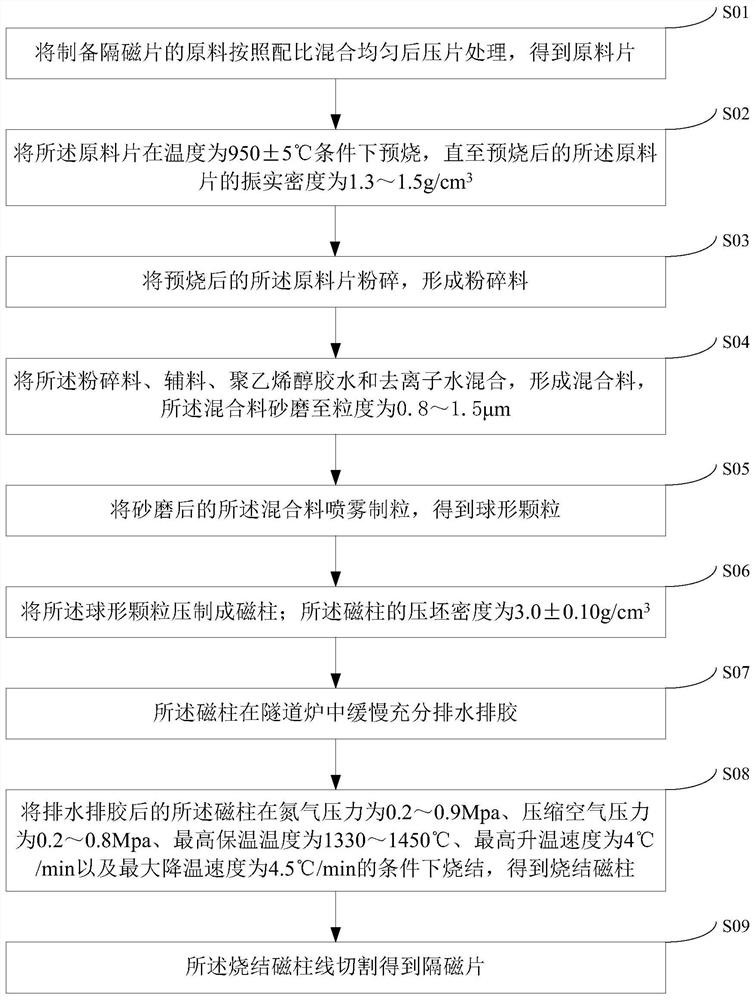

Magnetism insulation piece for wireless charging and preparing method

The invention provides a magnetism insulation piece for wireless charging and a preparing method. The high-Bs and low-loss magnetism insulation piece is prepared through the glue discharging by a tunnel kiln, the sintering by a bell type furnace and the slicing after the preparing of raw materials, the tabletting, the low-temperature pre-sintering, the doping of a trace amount of auxiliary materials and other substances, the spray granulating, and the press-forming. Meanwhile, by means of the preparing method, magnetism insulation pieces can be prepared in batches, and the production requirement is met.

Owner:娄底市玖鑫电子科技有限公司

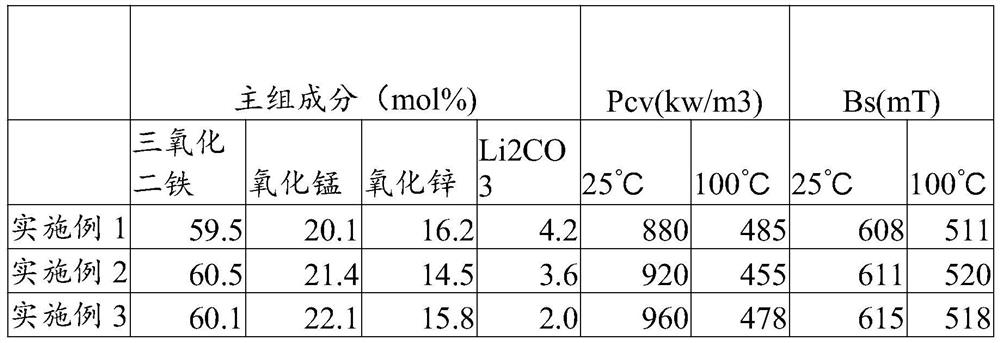

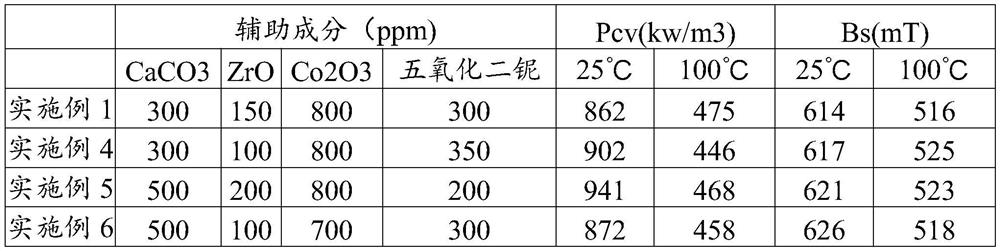

High-Bs low-power-consumption manganese-zinc soft magnetic ferrite material and preparation method thereof

InactiveCN112028619ALow costBs highInorganic material magnetismInductances/transformers/magnets manufactureTransformerSoft magnet

The invention is applicable to the technical field of soft magnetic ferrite materials, and provides a high-Bs low-power-consumption manganese-zinc soft magnetic ferrite material and a preparation method thereof. The high-Bs low-power-consumption manganese-zinc soft magnetic ferrite material comprises 55.4-60.5 mol% of ferric oxide, 15.3-22.5 mol% of manganese oxide, 10.5-17.6 mol% of zinc oxide and 2.0-5 mol% of lithium carbonate. The soft magnetic ferrite material has the characteristics of high Bs and low power consumption, the high Bs characteristic can be fully utilized, and the temperature rise can also be met. Meanwhile, the material cost is far lower than that of a magnetic powder core material, and the performance and cost requirements of the high-power high-power-density power transformer design can be better met.

Owner:WUXI SPINEL MAGNETICS

MnZn ferrite with function of high-frequency high-energy efficiency conversion and preparation method of MnZn ferrite

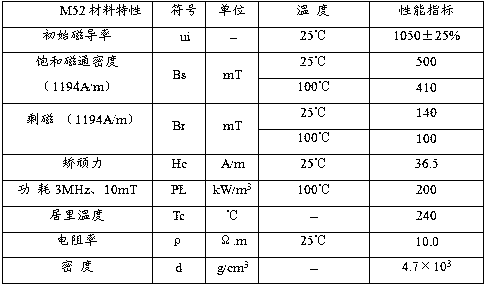

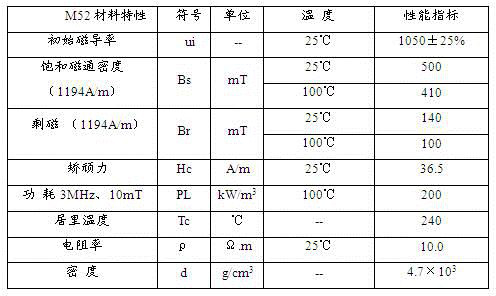

The invention discloses MnZn ferrite with a function of high-frequency high-energy efficiency conversion. The MnZn ferrite is prepared from a main body component and an additive component which have total mole percent content of 100%. A preparation method comprises steps of treatment of the main body component, addition of the additive component and sanding, spray granulation, green body preparation and sinter molding. According to the preparation method of the MnZn ferrite with the function of high-frequency high-energy efficiency conversion, the MnZn ferrite material with excellent intrinsicproperties is obtained by designing a proportion with lower Zn content and a low-temperature sintering process, has high Bs, small grain size and a high-resistivity grain boundary structure and is endowed with the characteristic of high-frequency high-energy efficiency conversion, power consumption of the MnZn ferrite at the high frequency of 3 MHz / 10mT is lower than 200 kW / m<3>, the blank in thehigh-frequency high-energy efficiency conversion material with permeability in the range of 900-1200 is filled up, the market demand for specific materials is met, and good economic benefits are created.

Owner:CHANGSHU HAOBO ELECTRONICS TECH CO LTD

Method for improving Bs of MnZn power ferrite material by moving valley point

ActiveCN111362684ABs highReduce lossInductances/transformers/magnets manufactureMagnetic materialsSpray GranulationMaterials preparation

The invention discloses a method for improving the Bs of a MnZn power ferrite material by moving a valley point, and relates to the field of MnZn power ferrite material preparation. The method comprises the following steps: 1) mixing Fe2O3, MnO and ZnO, and carrying out primary sanding; 2) adding glue, carrying out spray granulation, and then pre-sintering to obtain a pre-sintered material; 3) adding an additive into the pre-sintered material, and carrying out secondary sanding; 4) adding glue into the secondary sanded material, carrying out spray granulation, pressing into a standard ring, and sintering. The valley point is controlled and moved by controlling the Fe2O3 content and the Co2O3 content, so the loss is reduced, the Bs of the material is improved, and the problem that the valley point moving, the loss reducing and the Bs of the material cannot be considered at the same time in the prior art is solved; and the method is simple and convenient and is suitable for industrialization.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

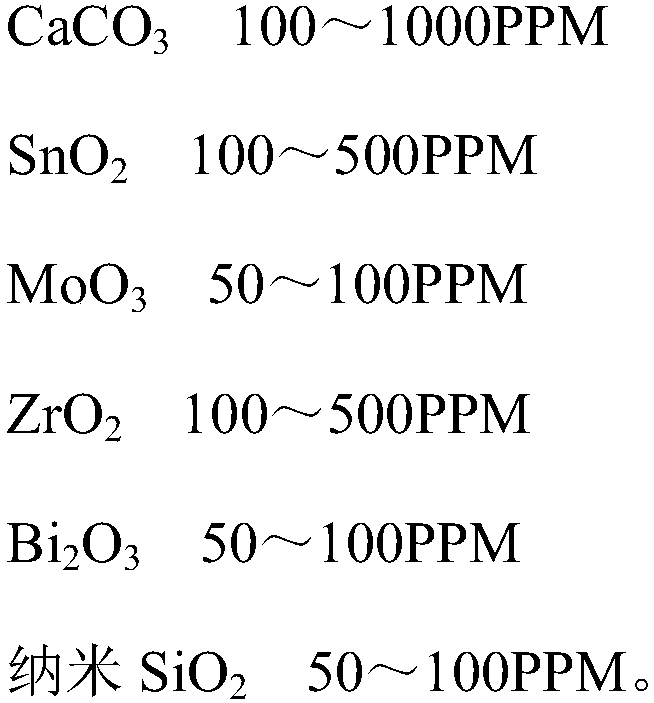

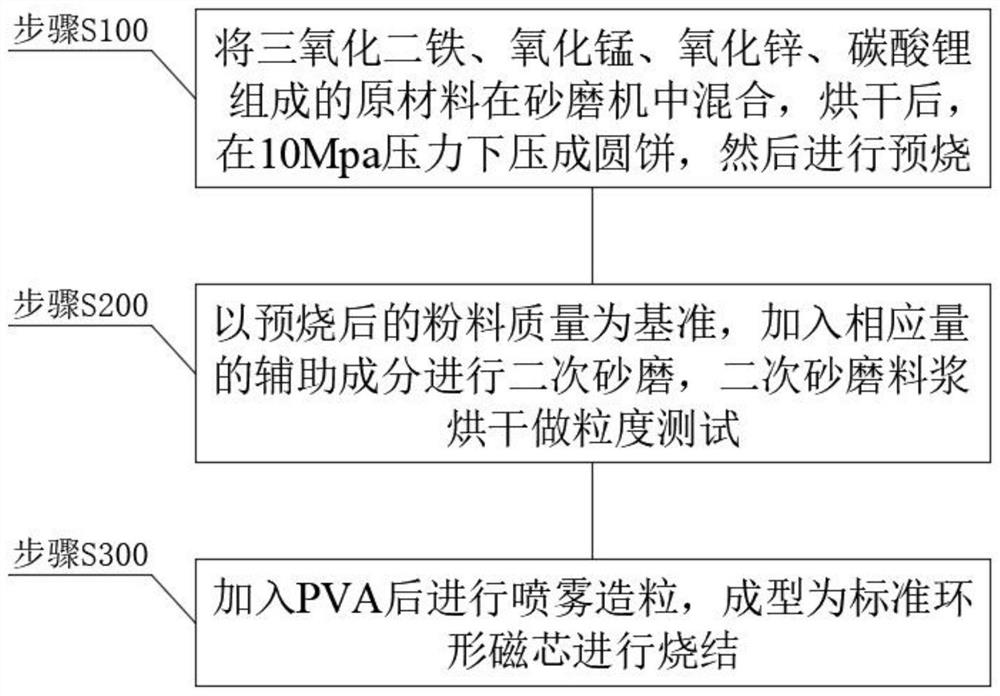

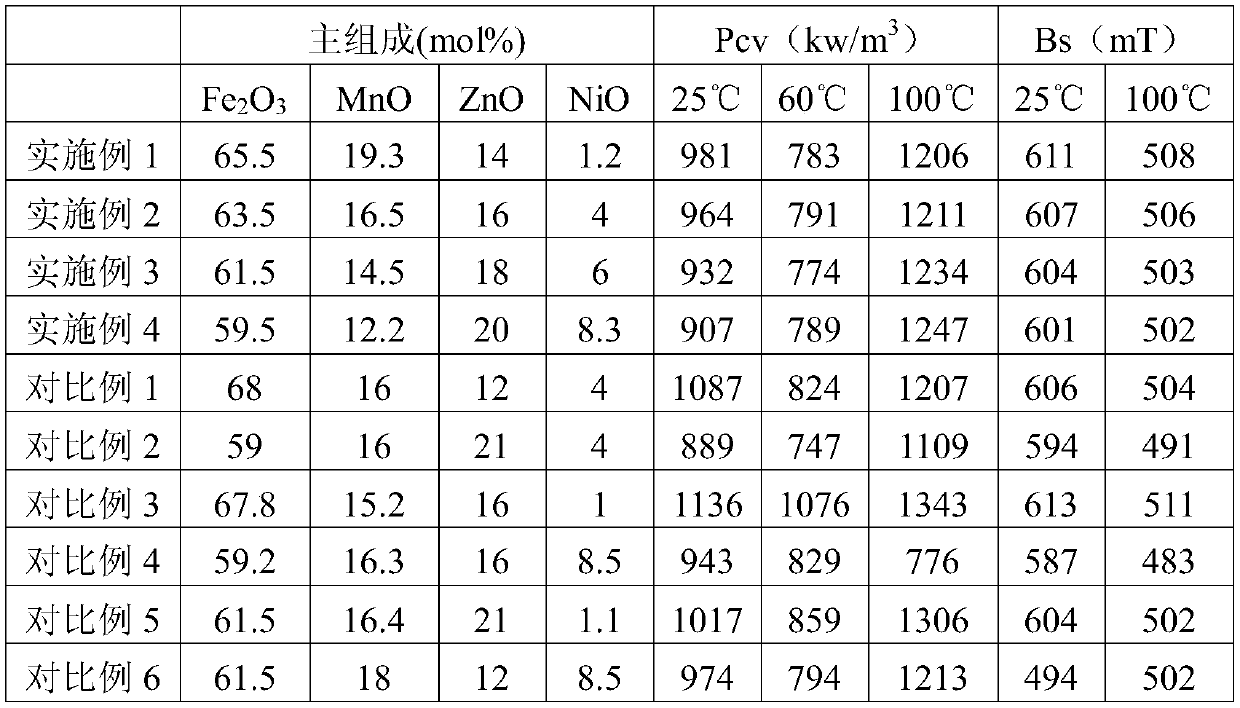

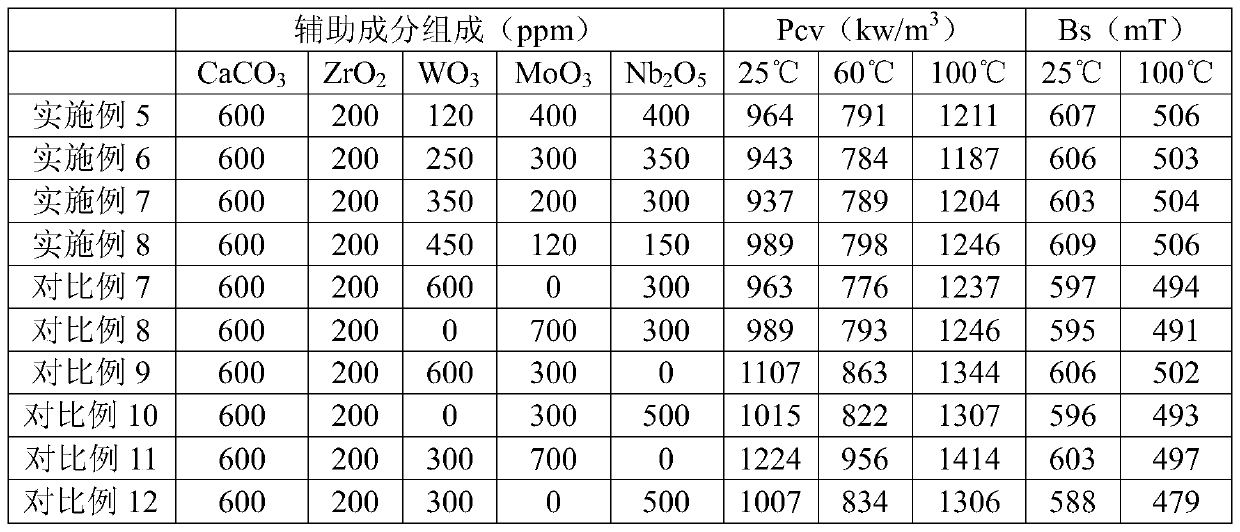

A 4-element formula ultra-high bs manganese zinc ferrite material and preparation method

The invention discloses a 4-element formula ultra-high Bs manganese zinc ferrite material and a preparation method. It includes the main components of ferric oxide, manganese oxide, zinc oxide and nickel oxide, and the auxiliary components are mainly calcium carbonate and zirconium dioxide, and the auxiliary components include tungsten trioxide, molybdenum trioxide and niobium pentoxide. One or more, the raw materials composed of Fe2O3, MnO, ZnO, NiO are mixed in a sand mill, after drying, they are pressed into a round cake under a pressure of 10Mpa, and then pre-fired; the quality of the powder after pre-burning As a benchmark, add the corresponding amount of auxiliary components for secondary sanding, and dry the secondary sanding slurry for particle size testing; add PVA and spray granulation, and shape it into a standard ring magnetic core for sintering. The beneficial effect of the present invention is that its high Bs characteristic can be fully utilized, and the temperature rise can also be satisfied; at the same time, the material cost is far lower than that of the magnetic powder core material, which can better meet the performance of high-power high-power-density power transformer design and cost requirements.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Low-loss manganese-zinc ferrite material for -20-140°C and manufacturing method thereof

The invention provides a low-loss manganese-zinc ferrite material for -20-140°C and a manufacturing method thereof. The ferrite material includes main components and auxiliary components, and the main components are Fe2O3: x mol%, MnO: y mol%, ZnO: z mol%, the auxiliary components are Co2O3: c wt% and NiO: n wt% based on the total weight of the main components, and the ratio of each component is x=54.5-55.5, z=7.5-9.5, y =100-x-z, c=0.25-0.45, n=0.3-0.9, and have 30≤A=2600-45x-9z≤80,-30≤B=150-3x-3y+371c-1.6n≤30 Relationship. Manganese-zinc ferrite materials are made through batching, mixing, pre-calcination, secondary grinding, granulation, molding, sintering and other process steps.

Owner:江门安磁电子有限公司

Ni-free manganese-zinc ferrite material for -20-140°C and manufacturing method thereof

The invention provides a Ni-free manganese-zinc ferrite material used at -20-140°C and a manufacturing method thereof. The ferrite material includes a main component and an auxiliary component, and the main component is Fe2O3: x mol%, MnO: y mol%, ZnO: z mol%, the auxiliary component is Co2O3: c wt% based on the total weight of the main component, wherein the ratio of each component is x=53.5-54.5, z=5.5-7.5, y=100‑x -z, c=0.25-0.45, and have the relationship of 70≤A=2580-45x-9z≤100, -30≤B=150-3x-3y+371c≤30. Manganese-zinc ferrite materials are made through batching, mixing, pre-calcination, secondary grinding, granulation, molding, sintering and other process steps.

Owner:江门安磁电子有限公司

A method of moving the valley point to improve the bs of mnzn power ferrite material

ActiveCN111362684BBs highReduce lossInductances/transformers/magnets manufactureMagnetic materialsSpray GranulationMaterials preparation

The invention discloses a method for moving a valley point to increase Bs of a MnZn power ferrite material, and relates to the field of MnZn power ferrite material preparation, comprising the following steps: 1) mixing Fe2O3, MnO and ZnO, and performing a sand mill; 2. ) Add glue, spray granulation, and then pre-fire to obtain pre-fired material; 3) Add additives to pre-fired material, and perform secondary sand grinding; 4) Add glue to secondary sand abrasive, spray granulate , pressed into a standard ring and then sintered, the present invention controls the Fe 2 o 3 Content and Co 2 o 3 content to control and move the valley point, while reducing the loss, improve the Bs of the material, which solves the problem that the prior art cannot simultaneously move the valley point, reduce the loss and improve the Bs of the material, and the method of the present invention is relatively simple and suitable for industrialization .

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

A kind of preparation method of iron-based amorphous alloy magnetic core and iron-based amorphous alloy

The invention provides a preparation method of a Fe-based amorphous alloy magnetic core. The preparation method of the Fe-based amorphous alloy magnetic core comprises the following steps of A) preparing materials according to components of a Fe-based amorphous alloy shown in a formula (I), and smelting the prepared raw materials into molten steel; B) cooling the molten steel by using a single-roller rapid quenching method to obtain a Fe-based amorphous alloy thin strip; C) winding the Fe-based amorphous alloy thin strip into a ring so as to obtain a Fe-based amorphous alloy thin strip closedmagnetic core; and D) carrying out heat treatment on the Fe-based amorphous alloy thin strip closed magnetic core so as to obtain the Fe-based amorphous alloy thin strip magnetic core. According to the preparation method of the Fe-based amorphous alloy magnetic core, on the basis of using a surface crystallization method to prepare a permanent permeability Fe-based amorphous alloy, the Bs of the Fe-based amorphous alloy is increased by adjusting alloy components and preparation process parameters so that the Bs of the Fe-based amorphous alloy is increased, and the permanent permeability performance within a wider magnetic field range is realized.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

A kind of preparation method of iron-silicon-aluminum soft magnetic alloy powder capable of self-passivation and insulation

ActiveCN106920621BHigh densityBs highTransportation and packagingMetal-working apparatusDecompositionMaterials science

The present invention provides a method for preparing Fe-Si-Al soft magnetic alloy powder capable of self-passivation and insulation, that is, during the alloy smelting process, the element P is rapidly cooled and cast to obtain crystal materials; The element P migrates to the crystal interface and is enriched on the crystal surface; followed by ammonia decomposition and annealing, the trace amount of H in the atmosphere 2 O combines with element P on the surface of the powder to make the powder self-passivated to form a phosphating layer. The passivated sendust powder has good insulating properties. The self-insulation of the powder prepared by the method of the present invention does not require a phosphating process, and can be pressed directly by adding resin and lubricant, thereby avoiding environmental protection and safety problems caused by the phosphating process while reducing production costs. The sendust magnetic core produced by this powder has extremely low magnetic loss characteristics, high Bs value of the magnetic core, and excellent DC superposition characteristics; the molding pressure is reduced, and the life of the press and mold is extended.

Owner:广州蓝磁新材料科技有限公司

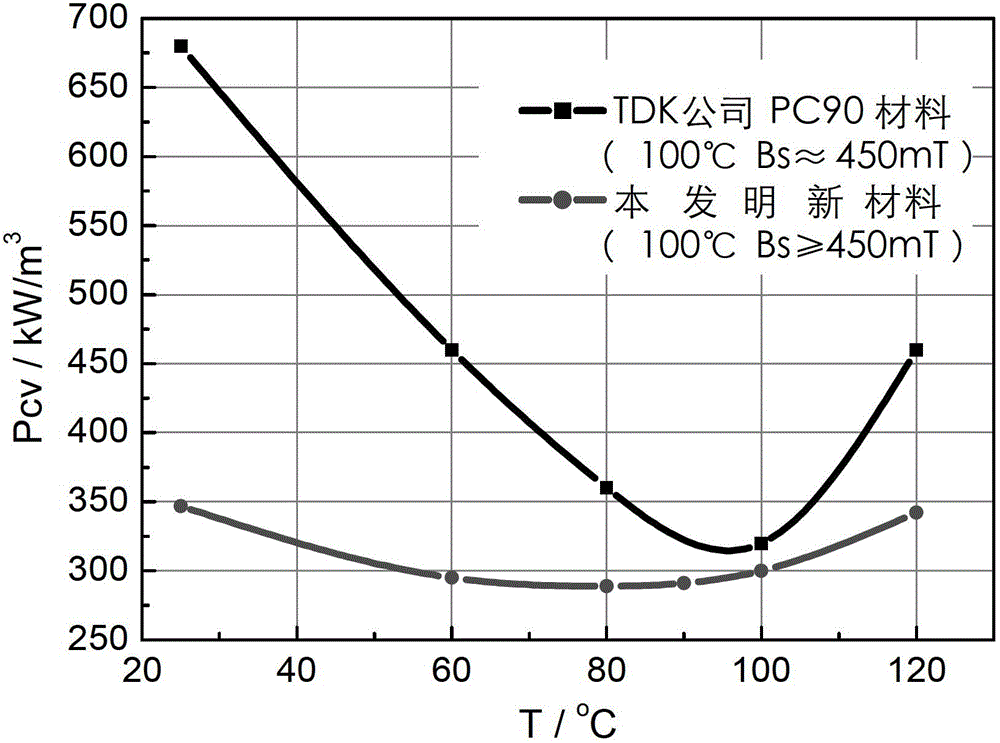

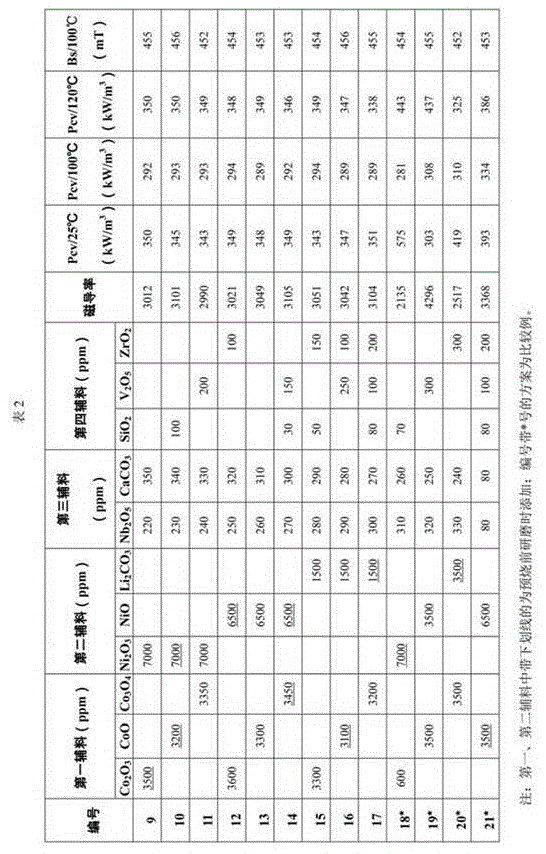

A kind of mnzn ferrite magnetic core with dual characteristics and its manufacturing method

ActiveCN102682946BOvercome the inability to take into account multiple featuresImprove performanceInorganic material magnetismInductances/transformers/magnets manufactureManganese oxideFerrite (magnet)

The invention discloses a MnZn ferrite magnetic core with double characteristics and a manufacture method. The magnetic core consists of main components and auxiliary components. The main components consist of Fe2O3 54-56 mol%, ZnO 5-10 mol% and the balance manganese oxide, wherein the sum of the Fe2O3, the ZnO and the manganese oxide is 100 mol%. The auxiliary components comprise a first auxiliary material, a second auxiliary material, a third auxiliary material and a selectable fourth auxiliary material, wherein the first auxiliary material is an oxide of Co, the second auxiliary material is one of Ni2O3, NiO or Li2CO3, the third auxiliary material is selected from CaCO3 and Nb2O5, and the fourth auxiliary material is selected from SiO2, V2O5 and ZrO2. The shortcoming that a common MnZn power ferrite material cannot integrate multiple characteristics is overcome, the MnZn ferrite magnetic core has the double characteristics of high temperature and Bs and wide temperature and low loss, the unit volume loss Pcv (100kHz, 200mT) of the magnetic core at the temperature of 25 DEG C to 120 DEG C is smaller than 350 kW / m<3>, the lowest loss at the temperature of about 90 DEG C is 300 kW / m<3>, and the saturation magnetic flux density can reach to 450 mT at the temperature of 100 DEG C.

Owner:江门安磁电子有限公司

A mnzn ferrite core without ni and having dual characteristics and its manufacturing method

ActiveCN103496963BOvercome the inability to take into account multiple featuresImprove performanceInorganic material magnetismManganese oxideMaterials science

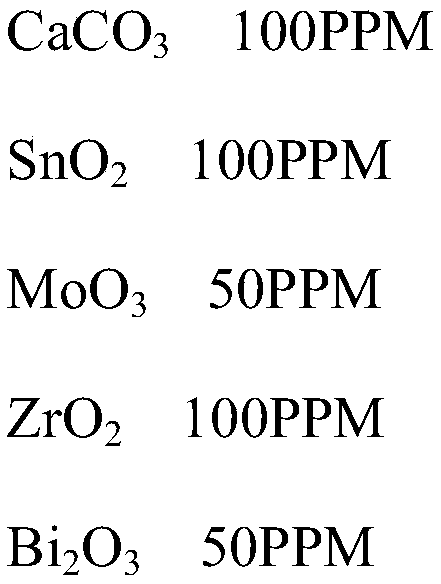

The invention provides a Ni-free MnZn power ferrite core with dual characteristics of high temperature, high Bs, wide temperature and low loss and its manufacturing method. The ferrite core includes a main component and an auxiliary component. The main component The material is 53mol%-54mol% of iron oxide based on Fe2O3, 39mol%-42mol% of manganese oxide based on MnO, and 4mol%-7mol% of zinc oxide based on ZnO; and the auxiliary components include Co2O3 or CoO or Co3O4 As the first auxiliary component, SiO2 and CaCO3 are used as the second auxiliary component, and any one or more selected from MoO3, TiO2, SnO2, Nb2O5, V2O5, Sm2O3, ZrO2 is used as the third auxiliary component. The MnZn power ferrite core with dual characteristics provided by the present invention has a unit volume loss Pcv (100kHz, 200mT) of less than 350kW / m3 from 25°C to 120°C, and a minimum loss of less than 300kW / m3 near 90°C, and It also has a saturation magnetic flux density as high as 450mT at 100°C.

Owner:江门安磁电子有限公司

High bs value, low power loss soft ferrite material and preparation method of magnetic core

The present invention proposes a preparation method of a high Bs value, low power loss soft ferrite material and magnetic core, optimizes the main formula and effective doping, develops a high Bs, low power consumption soft ferrite material, and the final product The grain size is 3-4μm, the initial magnetic permeability ui reaches more than 2200, and the power loss is 380-420kW / m at 80℃~120℃, 100kHz, 200mTBs value 3 , and the Bs value at 100°C is above 450mT; the multi-stage balanced atmosphere sintering method is adopted to control the density, grain size, porosity and their distribution inside and between the grains of the ferrite material, so that the soft magnetic ferrite The microstructure of the material is more effectively controlled, thereby ensuring that the main characteristic parameters of the material are harmoniously unified; the quality of the final product is high, and the production cost is reduced by more than 20%.

Owner:湖北华磁电子科技有限公司

A kind of nickel-zinc ferrite material, its preparation method and application

ActiveCN110357610BHigh strengthReduce high temperature impact resistanceSoft magnetNickel-zinc ferrite

The invention discloses a nickel-zinc ferrite material, and a preparation method and a use thereof. The nickel-zinc ferrite material comprises a main component and an additive, and the main componentcomprises Fe2O3, ZnO, NiO, CuO and MnO; and the additive comprises a group IVA oxide, a group IIA oxide, a group VIB oxide, a group IIIB oxide, a group VA oxide and a group IVB oxide. Formula development and trace element modification in the invention overcome the contradiction that improvement of the strength of a magnetic core reduces the high temperature shock resistance or improvement of the thermal shock resistance lowers the strength of the magnetic core, and the high-performance soft ferrite material with a high magnetic permeability, a high Bs value, a high strength and a high thermalshock resistance and for SMD power inductors is developed.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

High-frequency high-energy-efficiency conversion mnzn ferrite and preparation method thereof

The invention discloses MnZn ferrite with a function of high-frequency high-energy efficiency conversion. The MnZn ferrite is prepared from a main body component and an additive component which have total mole percent content of 100%. A preparation method comprises steps of treatment of the main body component, addition of the additive component and sanding, spray granulation, green body preparation and sinter molding. According to the preparation method of the MnZn ferrite with the function of high-frequency high-energy efficiency conversion, the MnZn ferrite material with excellent intrinsicproperties is obtained by designing a proportion with lower Zn content and a low-temperature sintering process, has high Bs, small grain size and a high-resistivity grain boundary structure and is endowed with the characteristic of high-frequency high-energy efficiency conversion, power consumption of the MnZn ferrite at the high frequency of 3 MHz / 10mT is lower than 200 kW / m<3>, the blank in thehigh-frequency high-energy efficiency conversion material with permeability in the range of 900-1200 is filled up, the market demand for specific materials is met, and good economic benefits are created.

Owner:CHANGSHU HAOBO ELECTRONICS TECH CO LTD

Nanocrystalline soft magnetic alloy magnetic core with low angle difference for smart meter and preparation method thereof

ActiveCN105861959BExcellent soft magnetic propertiesImprove thermal stabilityTransformers/inductances magnetic coresMagnetic materialsInductorSmart meter

The invention belongs to the field of magnetically soft alloy and particularly discloses a low-angle-difference nanocrystalline magnetically soft alloy magnetic core for an intelligent electric meter and a preparation method thereof. The molecular formula of the magnetic core is shown as follows: Fe100-a-b-c-d-eSiaBbMcCudNbeM'f, wherein a, b, c, d, e and f are atomic percents, 8<=a<=14, 2<=b<=10, 0.8<=c<=3, 1<=d<=4, 0.5<=e<=2, 0.02<=f<=0.5, the balance is Fe and unavoidable impurities, M is Al or Zn, and M' is one or more of Y, Gd, V, Mo, Mn, Ge, Er, Ga and Sn. The magnetic core which is prepared through a resultant magnetic field annealing treatment method and is excellent in soft magnetic property is further provided, and the requirement for high-precision measurement with a low-angle-difference mutual inductor for the intelligent electric meter is met.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD

Composite magnetic powder with high saturation magnetic induction, magnetic core and preparation method thereof

ActiveCN107240471BHigh Bs valueReduce loss valueTransportation and packagingMetal-working apparatusAlloyCobalt

The invention relates to a composite magnetic powder with high saturation magnetic induction intensity, which is made of powder A and powder B, and its proportion is: powder A 5-95wt%, powder B 5-95wt%; powder A is ferrosilicon powder, pure iron powder, sendust powder, iron-nickel powder, iron-nickel-molybdenum powder, iron-cobalt alloy powder; the powder B is iron-based amorphous alloy powder, iron-based nanocrystalline alloy powder, iron-nickel-based amorphous alloy powder At least one of alloy powder, iron-cobalt-based amorphous alloy powder, and iron-cobalt-based nanocrystalline alloy powder; the particle size of powder A and powder B is 8-200 μm. The magnetic core prepared with this composite magnetic powder has the characteristics of high Bs, low loss, low cost, and suitable for batch production. Works in the low to mid frequency (50Hz‑10kHz) range.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com