High bs value, low power loss soft ferrite material and preparation method of magnetic core

A soft ferrite, low-power technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of the Bs value not reaching the ideal state, high loss, high sintering process dependence, and reducing production costs. , low power loss, high product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The soft ferrite material of this embodiment includes main components and additive components, wherein,

[0041] The ratio of each main component is respectively:

[0042] Fe 2 o 3 68mol

[0043] MnO 17mol

[0044] ZnO 15mol

[0045] Relative to the total amount of main components, the weight ratios of each additive component are respectively:

[0046] CaCO 3 100PPM

[0047] SnO 2 100PPM

[0048] MoO 3 50PPM

[0049] ZrO 2 100PPM

[0050] Bi 2 o 3 50PPM

[0051] Nano-SiO with a particle size range of 50-100nm 2 50PPM.

[0052] The preparation steps of the soft ferrite core with high Bs value and low power loss are as follows:

[0053] First, each main component and each additive component are weighed and mixed uniformly.

[0054] Next, add pure water, dispersant, binder and defoamer to the mixed material, and perform ball milling to control the particle size distribution to 100-300 μm, and the weight percentage of water is 0.15%.

[0055] Then...

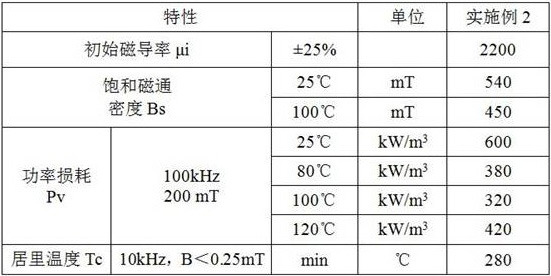

Embodiment 2

[0063] The soft ferrite material of this embodiment includes main components and additive components, wherein,

[0064] The ratio of each main component is respectively:

[0065] Fe 2 o 3 70mol

[0066] MnO 15mol

[0067] ZnO 15mol

[0068] Relative to the total amount of main components, the weight ratios of each additive component are respectively:

[0069] CaCO 3 500PPM

[0070] SnO 2 200PPM

[0071] MoO 3 70PPM

[0072] ZrO 2 300PPM

[0073] Bi 2 o 3 70PPM

[0074] Nano-SiO with a particle size range of 100-200nm 2 70PPM.

[0075] The preparation steps of the soft ferrite core with high Bs value and low power loss are as follows:

[0076] First, each main component and each additive component are weighed and mixed uniformly.

[0077] Next, add pure water, dispersant, binder and defoamer to the mixed material, and perform ball milling to control the particle size distribution to 100-300 μm, and the weight percentage of water content is 0.2%.

[00...

Embodiment 3

[0086] The soft ferrite material of this embodiment includes main components and additive components, wherein,

[0087] The ratio of each main component is respectively:

[0088] Fe 2 o 3 72 mol

[0089] MnO 17mol

[0090] ZnO 11mol

[0091] Relative to the total amount of main components, the weight ratios of each additive component are respectively:

[0092] CaCO 3 1000PPM

[0093] SnO 2 500PPM

[0094] MoO 3 100PPM

[0095] ZrO 2 500PPM

[0096] Bi 2 o 3 100PPM

[0097] Nano-SiO with a particle size range of 50-200nm 2 100PPM.

[0098] The preparation steps of the soft ferrite core with high Bs value and low power loss are as follows:

[0099] First, each main component and each additive component are weighed and mixed uniformly.

[0100] Next, add pure water, dispersant, binder and defoamer to the mixed material, and perform ball milling to control the particle size distribution to 100-300 μm, and the weight percentage of water is 0.25%.

[0101]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com