A kind of nickel-zinc ferrite material, its preparation method and application

A nickel-zinc ferrite and oxide technology, applied in the field of nickel-zinc ferrite materials, can solve the problems of large change in magnetic permeability and low Curie temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] A kind of preparation method of nickel-zinc ferrite material comprises the following steps

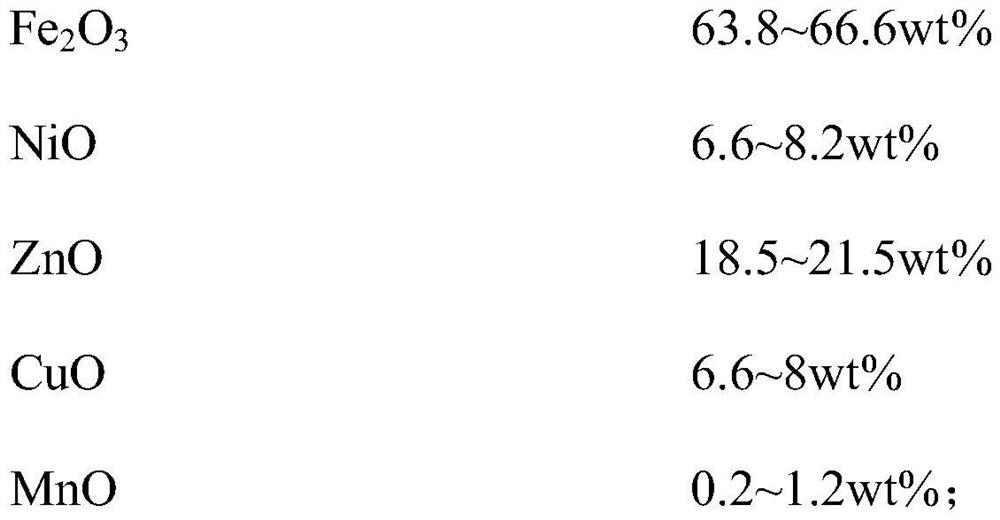

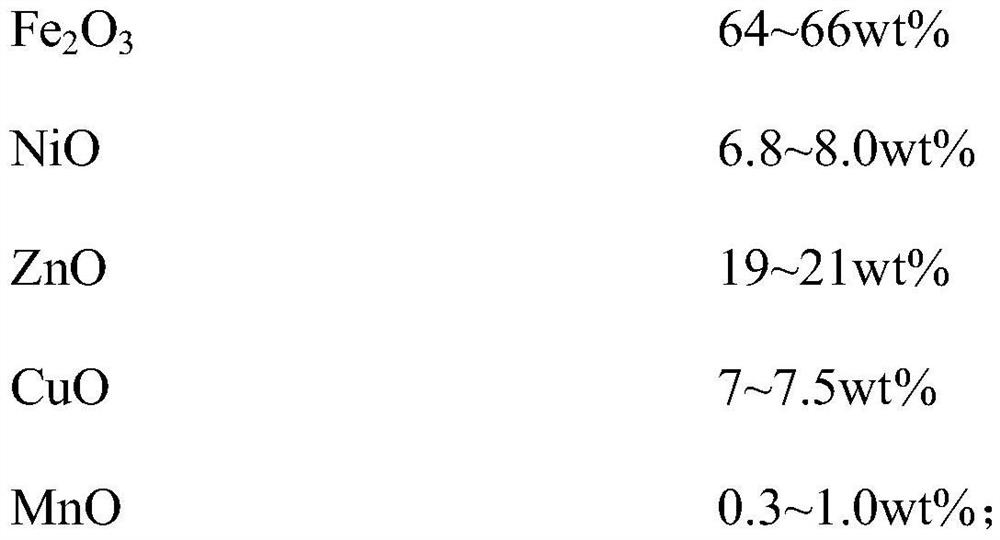

[0102] (1) 65.2wt% Fe 2 o 3 , 20.5wt% ZnO, 6.8wt% NiO, 7.2wt% CuO, 0.3wt% MnO and water were added to the sand mill for a sand mill for 40min, spray granulation;

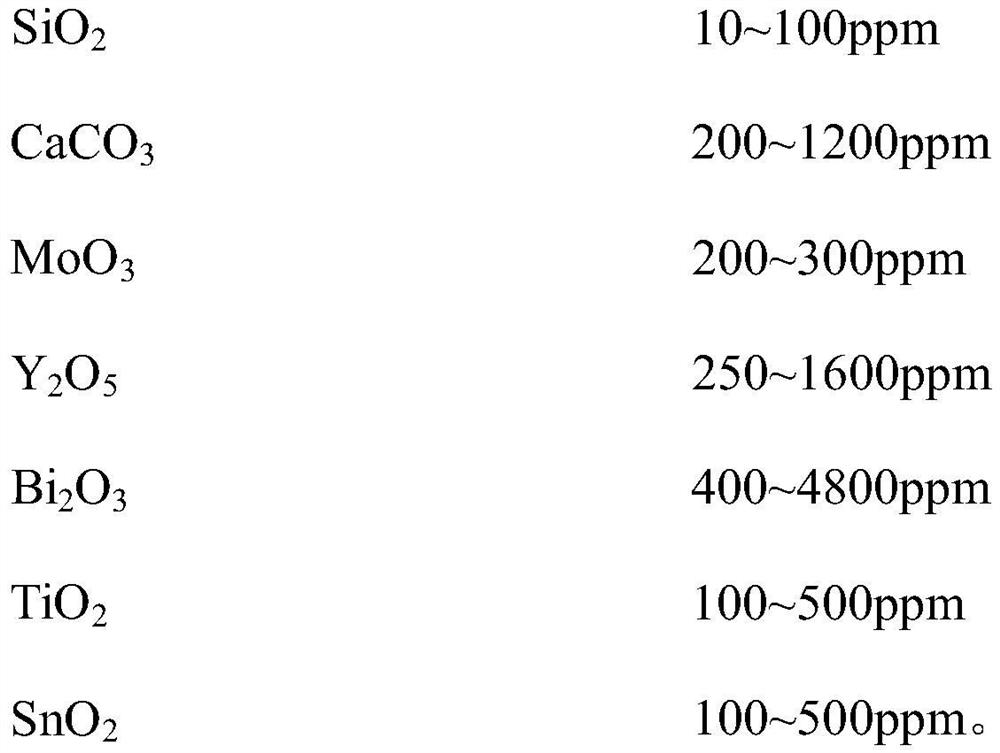

[0103] (2) Pre-burn the product obtained by granulation in a rotary kiln pre-calcination furnace at 900°C for 4h, the feed rate of the pre-calcination is 250kg / h, and add the pre-calcined product, additives and water into the sand mill Carry out secondary sand grinding, the time is 120min, the feed rate of described secondary sand grinding is 233kg / h, the particle diameter X50 that described secondary sand grinding obtains product is 1.2 μ m, and X99 is 3 μ m, then add n-octanol , defoamer and PVA are sprayed and granulated to obtain granules, the particle size of the product after granulation is 100 μm, and the content of each component in the additive is added according to the total mass ratio of the main componen...

Embodiment 2

[0106] The difference with Example 1 is that the content of each main component described in step (1) is: 65.4wt% Fe 2 o 3 , 20.1wt% ZnO, 7wt% NiO, 7.3wt% CuO, 0.2wt% MnO.

Embodiment 3

[0108] The difference with Example 1 is that the content of each main component described in step (1) is: 65wt% Fe 2 o 3 , 20wt% ZnO, 7wt% NiO, 7.5wt% CuO, 0.5wt% MnO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com