Ni-Zn soft-magnetic ferrite material, Ni-Zn ferrite, preparation method thereof and electrical inductance

A soft ferrite and ferrite technology, applied in the field of soft magnetic materials, can solve the problems of ferrite thermal shock and high DC bias, etc., and achieve excellent thermal shock performance, optimized adjustment, and excellent strength. and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

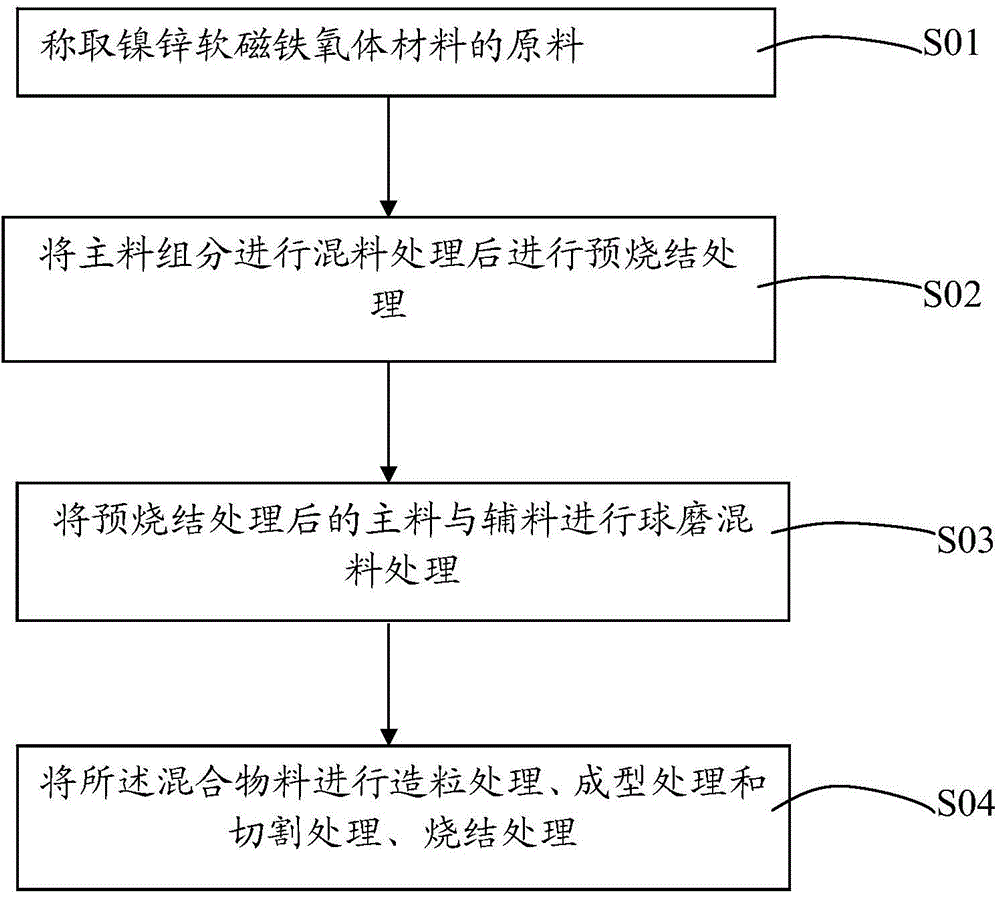

[0043] Correspondingly, on the basis of the nickel-zinc soft ferrite material of the embodiment of the present invention described above, the embodiment of the present invention also provides a method for preparing NiZn ferrite, the process flow is as follows figure 1 shown. The method comprises the steps of:

[0044] Step S01. Weighing the raw material of the nickel-zinc soft ferrite material: Weighing each component respectively according to the main material and the auxiliary material contained in the nickel-zinc soft ferrite material in the above-mentioned invention embodiment;

[0045] Step S02. Perform pre-sintering treatment after mixing the main material components: perform pre-sintering treatment after mixing the main material according to the proportion of the components contained therein;

[0046] Step S03. Performing ball milling treatment on the pre-sintered main material and auxiliary materials: performing wet ball milling after mixing the pre-sintered main mate...

Embodiment 1

[0067] A nickel-zinc soft ferrite material, the nickel-zinc soft ferrite material includes main materials and auxiliary materials, wherein,

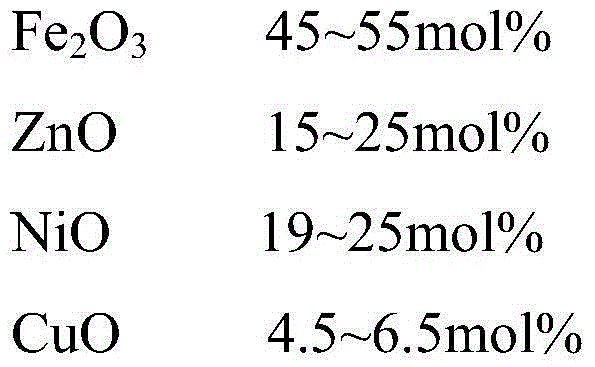

[0068] Based on the total mole of the nickel-zinc soft ferrite material as 100%, the main material includes the following mole percentage components:

[0069] Fe 2 o 3 49.42mol%, ZnO 24.12mol%, NiO 20.90mol%, CuO 5.52mol%;

[0070] Based on the total weight of the nickel-zinc soft ferrite material as 100%, the auxiliary material includes the following components in weight percentage:

[0071] 0.16 wt% Bi 2 o 3 , 0.1wt% Co 2 o 3 , 0.01wt% V 2 o 5 .

Embodiment 2

[0073] A nickel-zinc soft ferrite material, the nickel-zinc soft ferrite material includes main materials and auxiliary materials, wherein,

[0074] Based on the total mole of the nickel-zinc soft ferrite material as 100%, the main material includes the following mole percentage components:

[0075] Fe 2 o 3 49.58mol%, ZnO 24.05mol%, NiO 20.83mol%, CuO 5.50mol%;

[0076] Based on the total weight of the nickel-zinc soft ferrite material as 100%, the auxiliary material includes the following components in weight percentage:

[0077] 0.16 wt% Bi 2 o 3 , 0.2wt% Co 2 o 3 , 0.01wt% V 2 o 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Saturation magnetic induction | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com