MnZn ferrite with function of high-frequency high-energy efficiency conversion and preparation method of MnZn ferrite

A high-energy-efficiency, ferrite technology, applied in the field of MnZn ferrite material preparation, achieves the effects of low power consumption, good economic benefits, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

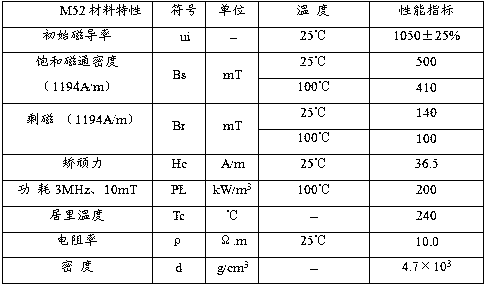

Image

Examples

Embodiment 1

[0037] The invention discloses a high-frequency high-energy-efficiency conversion MnZn ferrite, which includes a main component and an added component whose molar percentage sum is 100%; wherein, the main component includes the following molar percentage components Points: Fe 2 o 3 53-55 mol%, MnO 37.2-38.5 mol%, and the rest 6.5-9.5 mol% ZnO, the sum of the molar percentages of the main components is 100%.

[0038] The added components include the following components in weight percentage: CaCO 3 0.05~0.2wt%, SiO 2 0.005~0.2wt%, Nb 2 o 5 0~0.05wt%, Ta 2 o 5 0.05~0.15wt%.

[0039] Because the purity of the raw material affects the microstructure and performance of the product, the purity of the main components used in the present invention is higher, wherein the Fe 2 o 3 Purity ≥ 99.5%, SiO in it 2 The content of ≤100ppm, P 2 o 5 content≤30ppm, Al 2 o 3 The content of ≤30ppm, its specific surface area is greater than or equal to 4.05 m 2 / g; the purity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com