A carbon silica gel self-sealing core for drilling

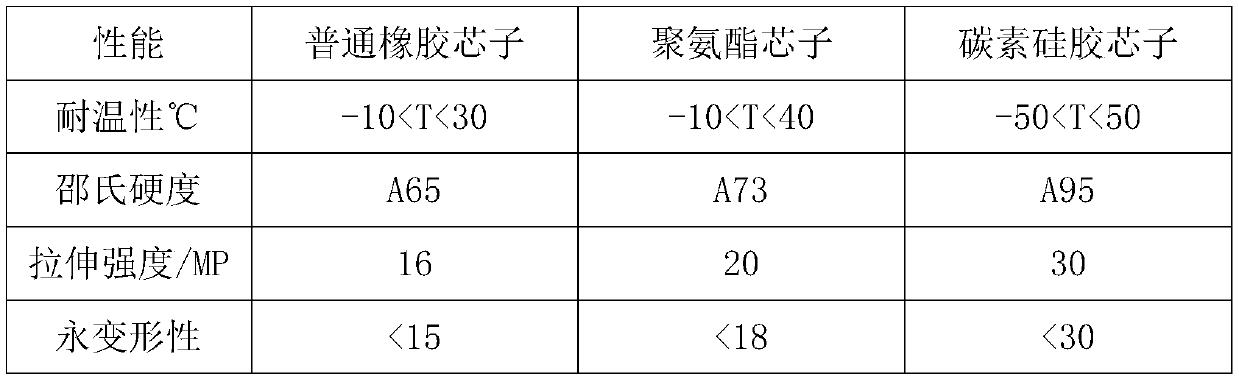

A core and carbon technology, used in the field of oil drilling, can solve the problems of small storage space for sealing oil, low strength of rubber core, poor lubrication performance, etc., and achieve good overall strength, improve compactness and strength, and improve anti-aging properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

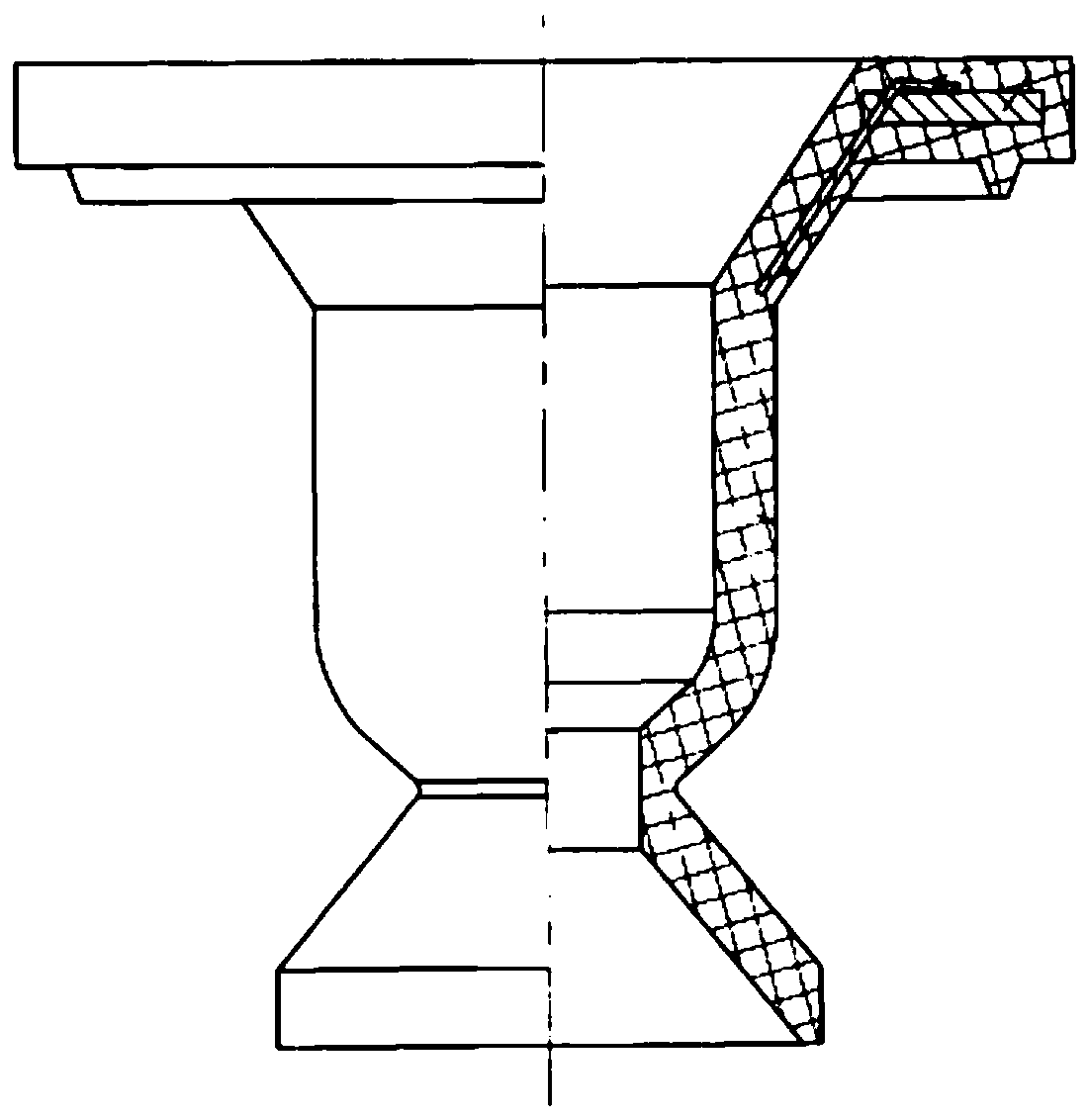

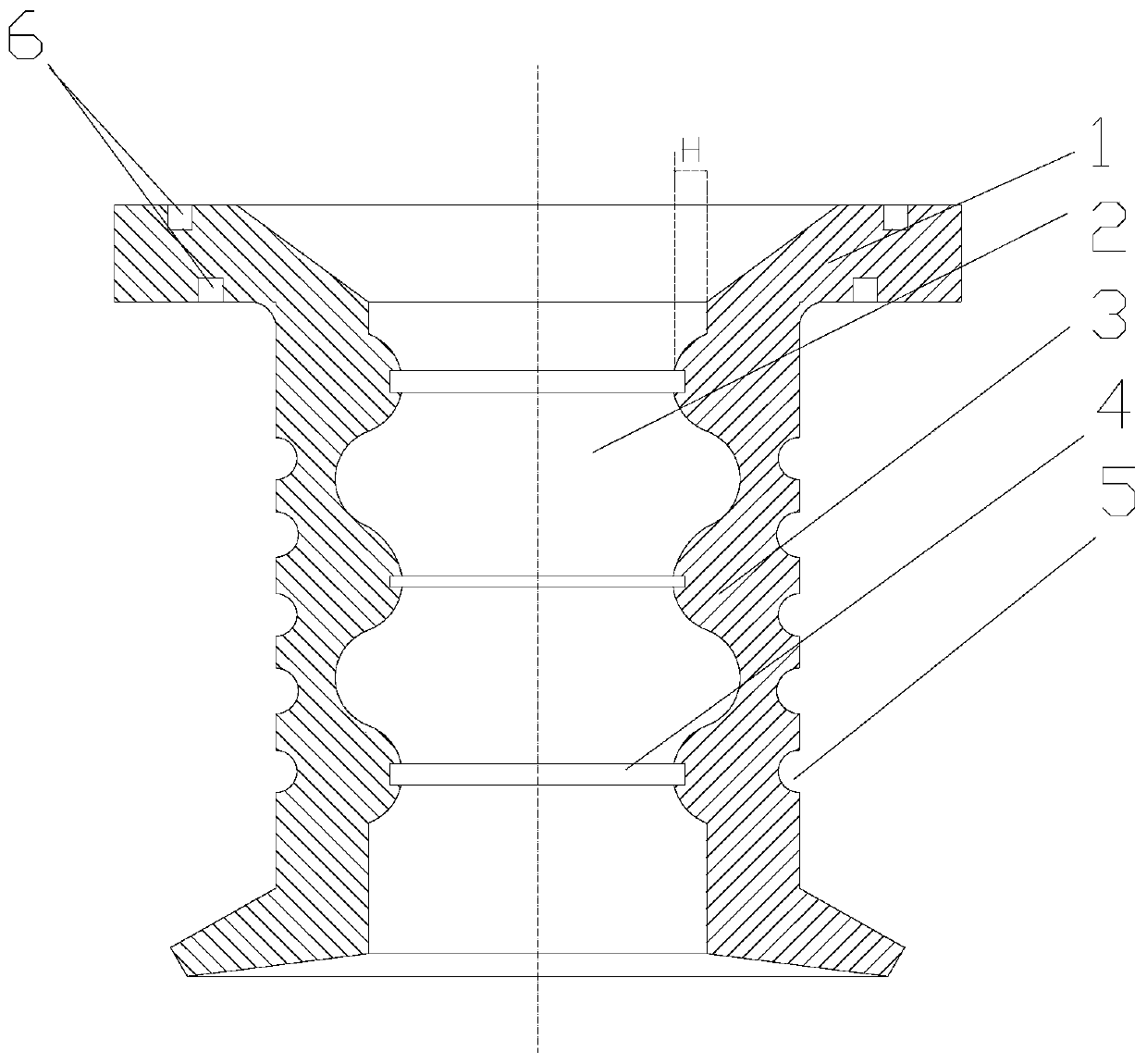

[0033] Examples, see attached figure 2 , a carbon silica gel self-sealing core, which includes a core body, the core body includes a cap portion 1 and a sealing portion 3 at the upper end, the middle part of the core body is a via hole 2, and the core body is mainly composed of It is composed of 12-18% carbon, 40-50% silica gel, 14-20% graphite nanometer and 20-25% nitrile rubber; Small stress concentration, on the other hand, can make lubricating oil flow better and enhance the lubricating effect. Sealing grooves 4 are provided on the convex part of the inner wall of the sealing part. Among them, the width of the lowest and highest sealing grooves is larger than that of the middle sealing groove. Width, preferably, the difference between adjacent two is 1 / 3 to 1 / 2, and a sealing ring is arranged inside the sealing groove, and adjacent sealing rings are arranged at intervals, and the interval distance is between the width of adjacent sealing grooves. and more than 4 times; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com