Method for reinforcing aluminum alloy profile through nano composite material

A technology of nanocomposite materials and aluminum alloy profiles, which is applied in the field of nanocomposite reinforced aluminum alloy profiles, can solve problems such as insufficient comprehensive performance to satisfy consumers, coarsening of aluminum alloy grains, and no specific solutions proposed, and achieve Synergistic enhancement of comprehensive performance, improvement of grain boundary stability, and reduction of internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

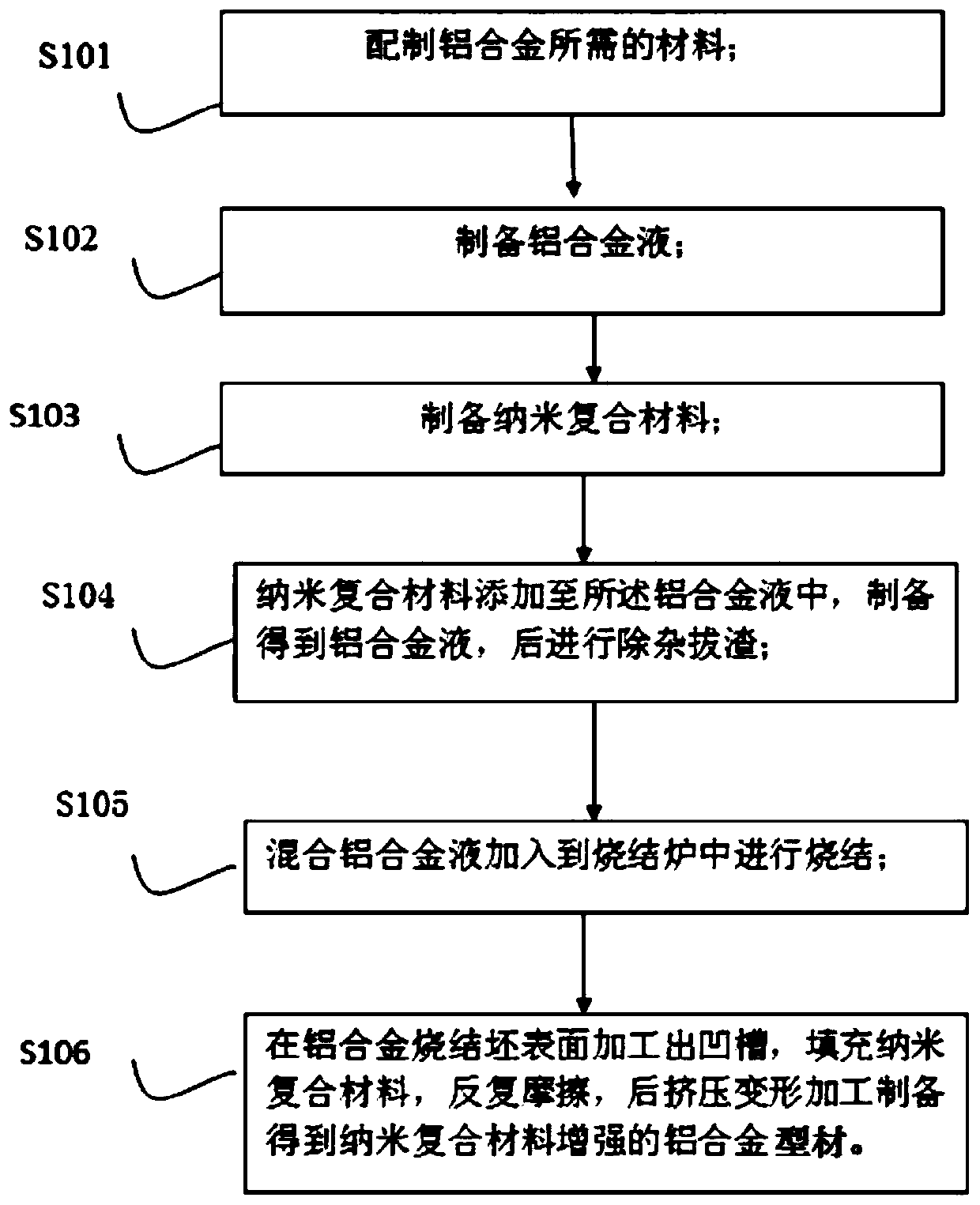

[0036] A method for reinforcing an aluminum alloy profile with a nanocomposite material, comprising the steps of:

[0037] (1) Materials required for preparing aluminum alloy: according to the atomic percentage of the composition of aluminum alloy: Si10.5%, Fe0.55%, Cu0.3%, Mn0.5%, Mg0.49%, Ti0.15%, Zr0 .34%, and the balance is Al, and the instant silicon, aluminum-iron alloy, pure copper, aluminum-manganese alloy, aluminum-titanium-boron alloy, magnesium ingot and aluminum ingot are weighed successively to complete the preparation of materials for preparing aluminum alloy;

[0038] (2) Heat and melt the aluminum ingot at 730°C, then add aluminum-iron alloy, pure copper, aluminum-manganese alloy, aluminum-titanium-boron alloy, magnesium ingot and instant silicon in sequence, under the condition of vacuum degree ≤5×10-2Pa Carrying out vacuum suspension smelting, the smelting temperature of the vacuum suspension smelting is 1500°C, and the smelting time is 10min, to obtain alumi...

Embodiment 2

[0048] A method for reinforcing an aluminum alloy profile with a nanocomposite material, comprising the steps of:

[0049] (1) Materials required for preparing aluminum alloy: according to the atomic percentage of the composition of aluminum alloy: Si13.0%, Fe0.55%, Cu0.68%, Mn0.5%, Mg0.49%, Ti0.15%, Zr0 .34%, and the balance is Al, and the instant silicon, aluminum-iron alloy, pure copper, aluminum-manganese alloy, aluminum-titanium-boron alloy, magnesium ingot and aluminum ingot are weighed successively to complete the preparation of materials for preparing aluminum alloy;

[0050] (2) Heat and melt the aluminum ingot at 750°C, then add aluminum-iron alloy, pure copper, aluminum-manganese alloy, aluminum-titanium-boron alloy, magnesium ingot and instant silicon in sequence, under the condition of vacuum degree ≤5×10-2Pa Carrying out vacuum suspension smelting, the smelting temperature of the vacuum suspension smelting is 1700°C, and the smelting time is 10min, to obtain alum...

Embodiment 3

[0060] A method for reinforcing an aluminum alloy profile with a nanocomposite material, comprising the steps of:

[0061] (1) Materials required for preparing aluminum alloy: according to the atomic percentage of the composition of aluminum alloy: Si12.5%, Fe0.30%, Cu0.45%, Mn0.30%, Mg0.45%, Ti0.10%, Zr0 .15%, and the balance is Al, and the instant silicon, aluminum-iron alloy, pure copper, aluminum-manganese alloy, aluminum-titanium-boron alloy, magnesium ingot and aluminum ingot are weighed successively to complete the preparation of materials for preparing aluminum alloy;

[0062] (2) Heat and melt the aluminum ingot at 740°C, then add aluminum-iron alloy, pure copper, aluminum-manganese alloy, aluminum-titanium-boron alloy, magnesium ingot and instant silicon in sequence, under the condition of vacuum degree ≤5×10-2Pa Carrying out vacuum suspension smelting, the smelting temperature of the vacuum suspension smelting is 1600°C, and the smelting time is 20min, to obtain alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com