A kind of austeric ductile iron grinding ball

A technology of nodular cast iron and austeric body, which is applied in the field of cast iron alloys, can solve the problems of easy white and bright areas in the grinding ball structure, difficult control of process parameters, and low production efficiency of ball mills, so as to improve mechanical properties, improve nodularization rate, and distribute refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

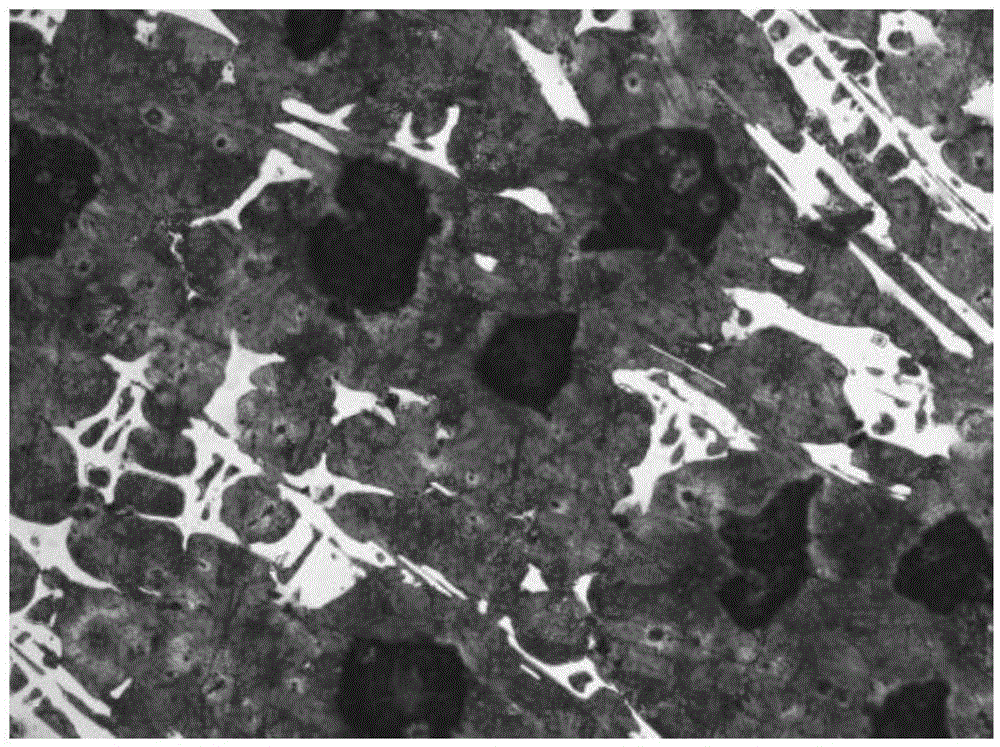

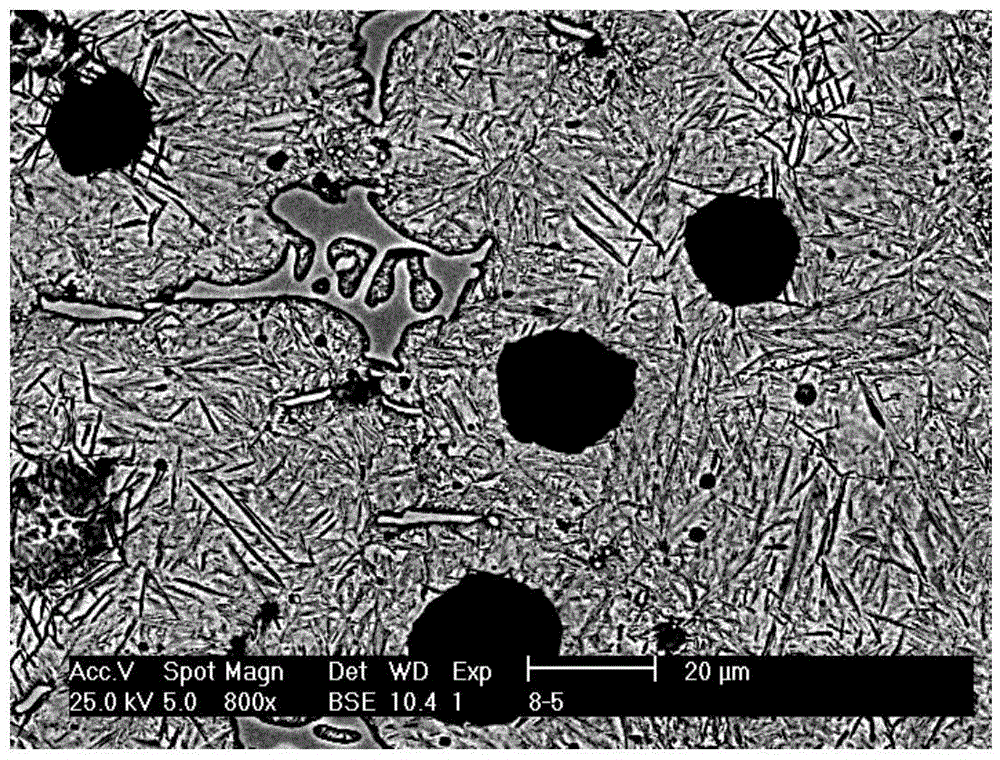

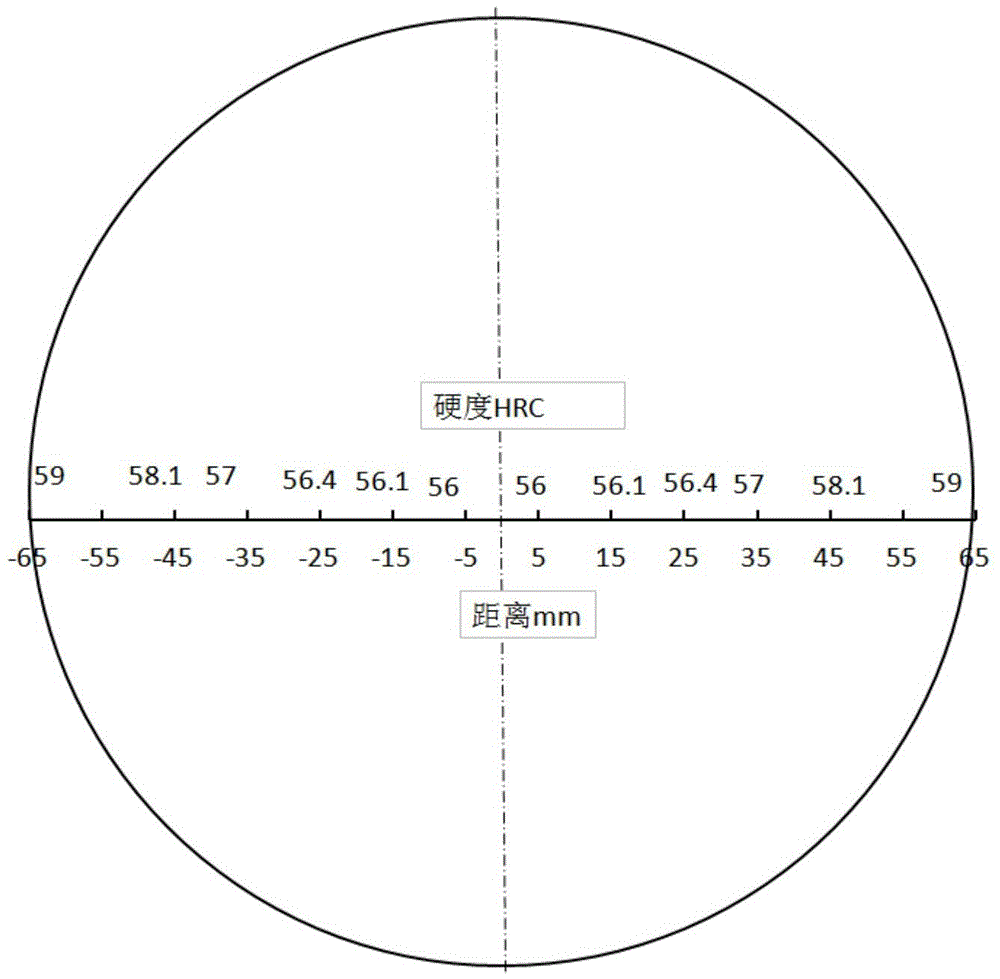

[0029] The mass percent of the chemical element composition of a kind of ausfertic ductile iron grinding ball of the present embodiment is: 3.5%C, 3.0%Si, 1.7%Mn, 0.7%Cr, 1.0%Mo, 1.0%Cu, 0.04%P, 0.01% S, 0.03% Mg, 0.02% Ce, 0.03% B, 0.06% Ti, 0.2% V and the rest is Fe, and is prepared by the following steps:

[0030] The first step, raw material preparation and smelting

[0031] According to the mass percentage of elements, it is 3.5%C, 3.0%Si, 1.7%Mn, 0.7%Cr, 1.0%Mo, 1.0%Cu, 0.04%P, 0.01%S and the rest is Fe. The raw materials for preparation: pig iron, scrap steel, silicon For iron, ferromanganese, ferrochrome, ferromolybdenum and copper, put the prepared raw materials into an intermediate frequency induction furnace, heat up until all raw materials are melted, and smelt into ausferitic nodular cast iron raw iron, and the furnace temperature is 1500 ℃;

[0032] The second step, spheroidization treatment, inoculation treatment and microalloying treatment

[0033] Spheroidiz...

Embodiment 2

[0038] The mass percent of the chemical element composition of a kind of ausfertic ductile iron grinding ball of the present embodiment is: 3.3%C, 2.5%Si, 2.5%Mn, 1.5%Cr, 0.3%Mo, 0.1%Cu, 0.06%P, 0.015% S, 0.04% Mg, 0.03% Ce, 0.05% B, 0.09% Ti, 0.12% V and the rest is Fe, and is prepared by the following steps:

[0039] The first step, raw material preparation and smelting

[0040] According to the mass percentage of elements, it is 3.3%C, 2.5%Si, 2.5%Mn, 1.5%Cr, 0.3%Mo, 0.1%Cu, 0.06%P, 0.015%S and the rest is Fe. The raw materials for preparation: pig iron, scrap steel, silicon For iron, ferromanganese, ferrochrome, ferromolybdenum and copper, put the prepared raw materials into an intermediate frequency induction furnace, heat up until all raw materials are melted, and smelt into ausferitic nodular cast iron raw iron, and the furnace temperature is 1550 ℃;

[0041] The second step, spheroidization treatment, inoculation treatment and microalloying treatment

[0042] Spheroi...

Embodiment 3

[0047] The mass percent of the chemical element composition of a kind of ausferic ductile iron grinding ball of the present embodiment is 3.7%C, 2.0%Si, 1.0%Mn, 3.0%Cr, 0.1%Mo, 0.8%Cu, 0.08%P, 0.020 %S, 0.05% Mg, 0.04% Ce, 0.07% B, 0.12% Ti, 0.03% V and the rest is Fe, and is prepared by the following steps:

[0048] The first step, raw material preparation and smelting

[0049] According to the mass percentage of elements, it is 3.7%C, 2.0%Si, 1.0%Mn, 3.0%Cr, 0.1%Mo, 0.8%Cu, 0.08%P, 0.02%S and the rest is Fe. Raw materials: pig iron, scrap steel, silicon For iron, ferromanganese, ferrochrome, ferromolybdenum and copper, put the prepared raw materials into an intermediate frequency induction furnace, heat up until all the raw materials are melted, and smelt into ausferitic nodular cast iron raw iron, and the furnace temperature is 1520 ℃;

[0050] The second step, spheroidization treatment, inoculation treatment and microalloying treatment

[0051]Spheroidizing treatment, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com