Preparation method of ultrasonic Mg-Al-Zn-Mn-Nd corrosion resistant rare earth magnesium alloy

A rare-earth magnesium and alloy technology, which is applied in the field of alloy or non-ferrous metal processing, can solve the problem of anode corrosion rate reduction and achieve the effects of uniform tissue distribution, fine tissue distribution, and improved corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

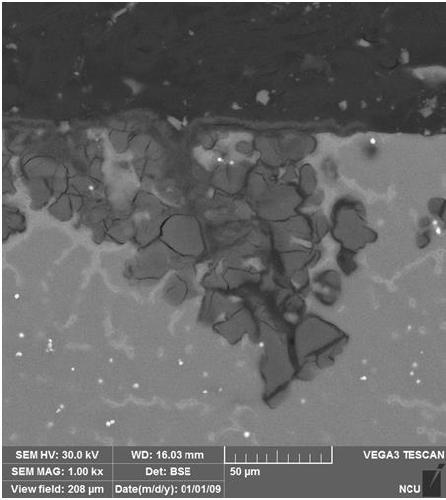

[0012] Embodiment 1: The composition of the Mg-Al-Zn-Mn magnesium alloy of this embodiment and the weight percentage of each component are: Al: 7.21%; Zn: 1.23%; Mn: 0.72%; the balance is Mg element.

[0013] Melting and casting process: Put the Mg-Al-Zn-Mn alloy into a crucible at a furnace temperature of 730°C and heat it until it melts, then keep it warm for 8 minutes; then insert the ultrasonic horn into the above alloy melt for intermittent ultrasonic treatment, ultrasonic The intensity is 1000w, each ultrasonic time is 12 seconds, the intermittent time is 13 seconds, and the total ultrasonic time is 700 seconds; finally, the alloy melt is quickly poured into the preheated metal mold.

[0014] Results: The alloy in this example was corroded in 3.5% NaCl solution at room temperature for 24 hours, and the weight loss corrosion rate was 0.324mg cm -2 ·day -1 .

Embodiment 2

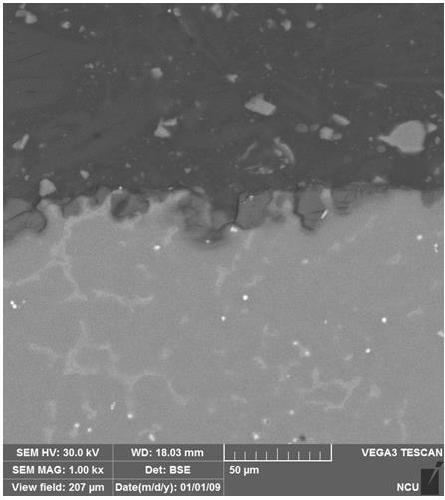

[0015] Embodiment 2: The Mg-Al-Zn-Mn-Nd corrosion-resistant rare earth magnesium alloy of this embodiment, its composition and the weight percentage of each component are: Al: 7.86%; Zn: 1.31%; Mn: 0.75%; Nd : 0.50%; the balance is Mg element.

[0016] Melting and casting process: Put the Mg-Al-Zn-Mn alloy into a crucible at a furnace temperature of 750°C and heat it to melt, then add a small piece of Mg-20%Nd master alloy wrapped in aluminum foil, and keep it warm for 9 minutes until the alloy is completely melted. Melting; then extend the ultrasonic horn into the alloy melt for intermittent ultrasonic treatment, the ultrasonic intensity is 1200w, each ultrasonic time is 10 seconds, the intermittent time is 15 seconds, and the total ultrasonic time is 800 seconds; finally, the alloy melt is quickly Pouring in preheated metal molds.

[0017] Results: The alloy of this example was corroded in 3.5% NaCl solution at room temperature for 24 hours, and the weight loss corrosion ra...

Embodiment 3

[0018] Embodiment 3: The Mg-Al-Zn-Mn-Nd corrosion-resistant rare earth magnesium alloy of this embodiment, its composition and the weight percentage of each component are: Al: 8.65%; Zn: 1.48%; Mn: 0.87%; Nd : 1.00%; the balance is Mg element.

[0019] Melting and casting process: Put the Mg-Al-Zn-Mn alloy into a crucible at a furnace temperature of 740°C and heat it until it melts, then add a small piece of Mg-20%Nd master alloy wrapped in aluminum foil, and keep it warm for 10 minutes until the alloy is completely melted. Melting; then extend the ultrasonic horn into the alloy melt for intermittent ultrasonic treatment, the ultrasonic intensity is 1800w, each ultrasonic time is 15 seconds, the intermittent time is 5 seconds, and the total ultrasonic time is 900 seconds; finally, the alloy melt is quickly Pouring in preheated metal molds.

[0020] Results: The alloy of this example was corroded in 3.5% NaCl solution at room temperature for 24 hours, and the weight loss corro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com