Mine safety helmet

A helmet and safety technology, applied in helmets, helmet covers, applications, etc., can solve problems such as property loss, casualties, and lag in safety equipment research and development, and achieve the effect of improving safety, enhancing fire resistance and compression resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

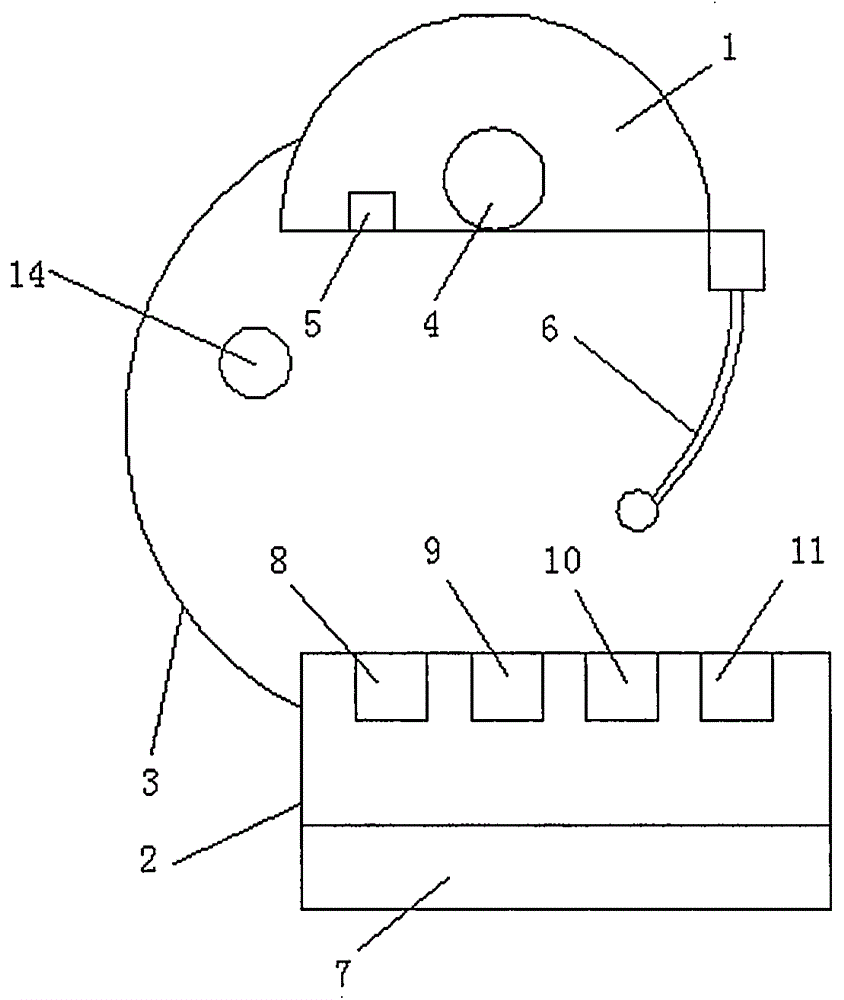

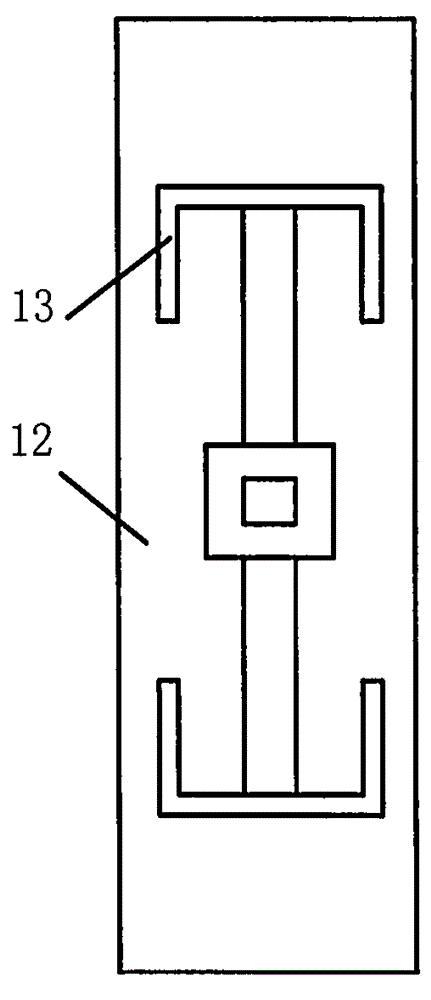

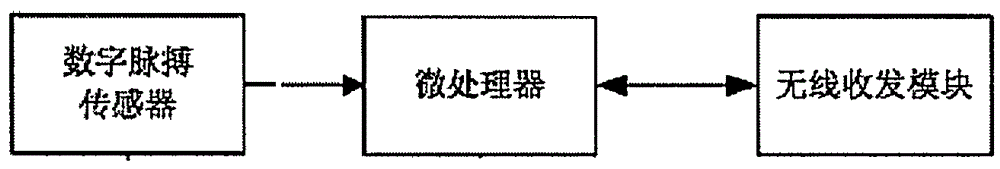

[0015] The present invention provides a kind of mining safety helmet for existing deficiency, as Figure 1-2 As shown, it includes a helmet body 1 and a belt box 2. The helmet body 1 and the belt box 2 are connected by a cable 3. It is characterized in that the helmet body 1 is coated with a silver layer, and the helmet body 1 includes an inner layer, a filling Layer, galvanized layer and coating, the inner layer is made of PC material, the filling layer is asbestos layer, the galvanized layer is painted by electrostatic spraying, and the coating is made of aluminum oxide, lanthanum oxide, beryllium oxide , calcium oxide, zirconia, uranium oxide, magnesium oxide, cerium oxide, thorium oxide, silicon dioxide and titanium dioxide, or at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com