Preparation method for high-density pure tungsten, pure molybdenum, tungsten alloy material and molybdenum alloy material

An alloy material and alloy technology, which is applied in the preparation of pure molybdenum and its alloy materials, high-density pure tungsten, and high-density refractory metals, can solve the problems of high cost and single shape, and achieve cost reduction and compensation single shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

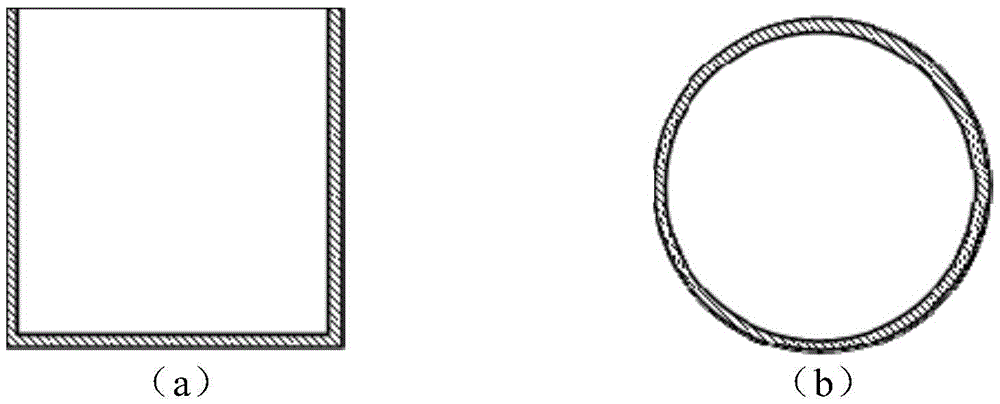

[0035] In this example, a pure tungsten crucible with a relative density of 98.5% is prepared. The outer dimension of the tungsten crucible is Φ138×140, and the wall thickness is 5mm, such as figure 1 As shown, the specific steps are as follows:

[0036] (1) The tungsten powder (average particle size is 2.5μm) is crushed with a jet crusher, the charging speed is 1.0kg / min, the air pressure is 0.8MPa, the speed of the classifier is 60Hz, and the average particle size of the crushed tungsten powder is 2.3 μm.

[0037] (2) Pack the crushed tungsten powder into a cold isostatic pressing mold and carry out cold isostatic pressing to obtain a billet; the pressure of cold isostatic pressing is 240MPa, the holding time is 20min, and the pressure release rate is 4MPa / min.

[0038] (3) The blank obtained in (2) is sintered in a medium frequency induction heating furnace; the sintering is carried out under a hydrogen atmosphere, and the hydrogen flow rate is 15m 3 / hour, the sinterin...

Embodiment 2

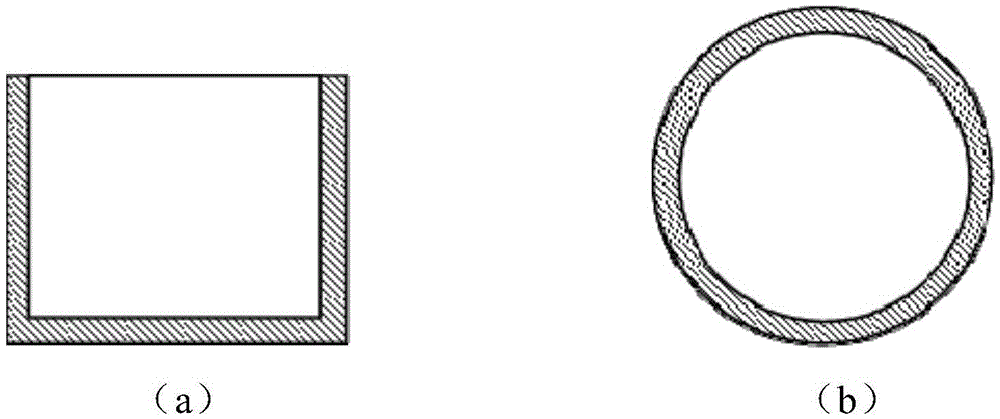

[0041] This example prepares a pure molybdenum crucible with a relative density of 99%. The outer dimensions of the molybdenum crucible are Φ145×110, and the wall thickness is 10 mm, such as figure 2 As shown, the specific steps are as follows:

[0042] (1) Molybdenum powder (average particle size is 3.5μm) is crushed with a jet crusher, the charging speed is 0.5kg / min, the air pressure is 1.2MPa, the classifier speed is 30Hz, and the average particle size of the molybdenum powder after crushing is 3.3 μm.

[0043] (2) Put the crushed molybdenum powder into a cold isostatic pressing mold and carry out cold isostatic pressing to obtain a billet; the pressure of cold isostatic pressing is 220MPa, the holding time is 20min, and the pressure release rate is 3.5MPa / min.

[0044] (3) The blank obtained in (2) is sintered in a medium frequency induction heating furnace; the sintering is carried out under a hydrogen atmosphere, and the hydrogen flow rate is 12m 3 / hour, the sint...

Embodiment 3

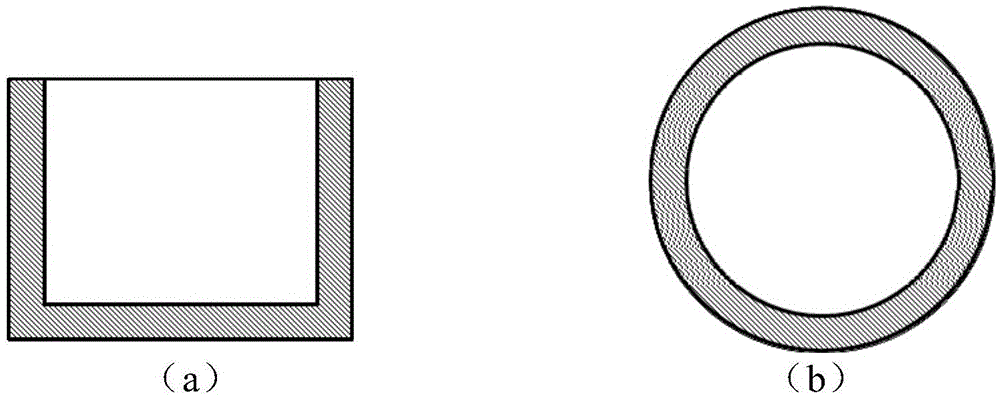

[0047] This example prepares a tungsten-lanthanum oxide alloy crucible with a relative density of 99%. The crucible has an overall size of Φ145×110 and a wall thickness of 15mm, such as image 3 As shown, the specific steps are as follows:

[0048] (1) the tungsten-lanthanum oxide powder (average particle size is 2.3 μm, the mass percentage of lanthanum oxide is 1%, adopts the mixing machine to mix and forms), carries out crushing with jet crusher, and charging speed is 0.8kg / min, The air pressure is 0.6MPa, the speed of the classifier is 20Hz, and the average particle size of the crushed alloy powder is 2.0μm.

[0049] (2) Pack the alloy powder after crushing into the cold isostatic pressing mold and carry out the cold isostatic pressing process, thereby obtain the billet; min.

[0050] (3) The blank obtained in (2) is sintered in a medium frequency induction heating furnace; the sintering is carried out under a hydrogen atmosphere, and the hydrogen flow rate is 15m 3 / hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com