Discharge lamp

A discharge lamp and cathode technology, which is applied in the field of xenon lamps, can solve the problems of high brightness of the light source and reduced light quantity, and achieve the effect of stabilizing the glow point and high brightness of the glow point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

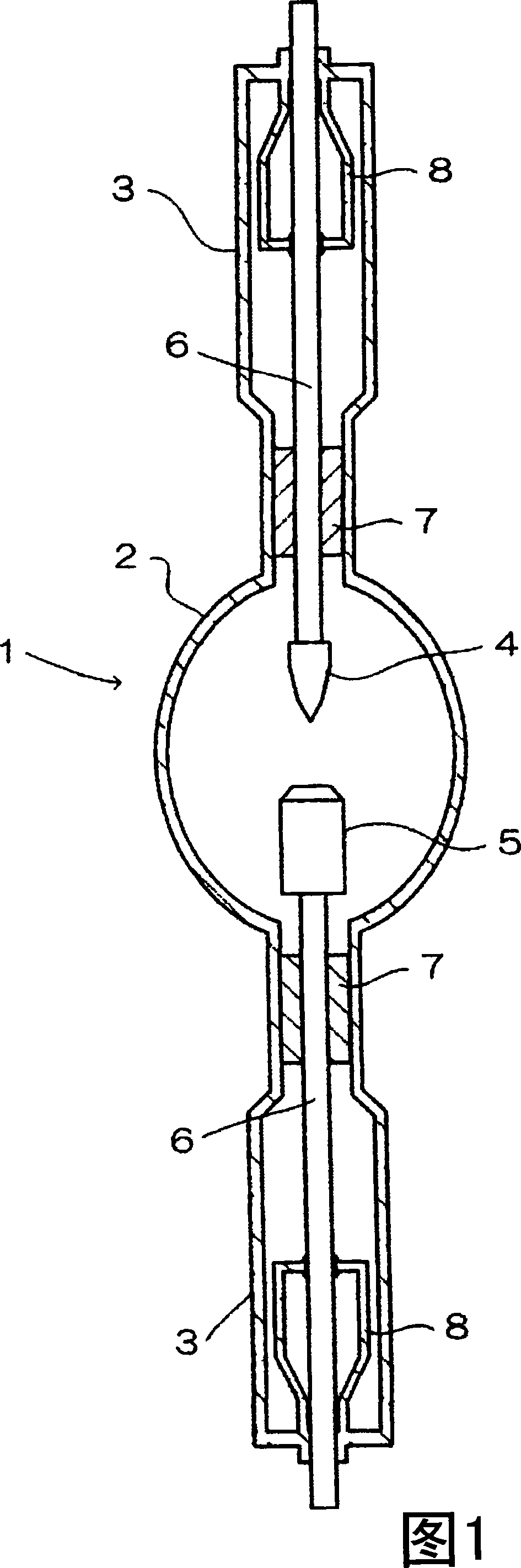

[0027] The first embodiment of the present invention will be described. Fig. 1 is an explanatory cross-sectional view showing the structure of a discharge lamp 1 of the present invention.

[0028] This discharge lamp 1 includes a bulb made of quartz glass including an arc tube 2 and a sealed tube 3 , and a cathode 4 and an anode 5 provided to face each other inside the arc tube 2 .

[0029] Xenon gas is sealed inside a substantially spherical arc tube 2 , and sealing tubes 3 are provided integrally and continuously at both ends of the arc tube 2 . The anode 5 and the cathode 4 are respectively fitted to the tip of an electrode rod 6 made of tungsten. A holding cylinder 7 made of quartz glass is arranged inside the sealed tube 3 on the arc tube 2 side, and an electrode rod 6 supporting the anode 5 and the cathode 4 is inserted through a through hole formed in the center of the holding cylinder 7 . The reduced portion is formed by heating the sealing tube 3 in which the holdin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com