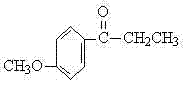

A kind of preparation method of pharmaceutical intermediate p-methoxypropiophenone

A technology of p-methoxybenzene and methoxybenzoic acid, which is applied in the field of preparation of pharmaceutical intermediate p-methoxypropiophenone, can solve problems such as high product cost, difficult separation and purification, and unsatisfactory results, and achieve Low cost, simple separation and purification process, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a four-necked reaction flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 15.2 g of p-methoxybenzoic acid, 44.4 g of propionic acid, and 7.5 g of a composite catalyst in sequence. After the addition, start stirring to control the condensation reaction temperature The temperature is about 135-145°C, and the condensation reaction is carried out by stirring for 7-13h, and the excess propionic acid is distilled off, and the temperature continues to rise until the gas begins to escape at 275°C, and the decarboxylation reaction is carried out at the temperature of 275-285°C. Use 95% ethanol solution to absorb the escaped gas and the distilled liquid. After 1-2h, there is no liquid distilled out in the four-necked reaction bottle, then stop the reaction, then cool and crystallize to obtain the p-methoxypropiophenone product. The yield of methoxypropiophenone reaches 71.25%, and the melting point is 27-28°C.

Embodiment 2

[0021] In a four-necked reaction flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 15.2 g of p-methoxybenzoic acid, 51.8 g of propionic acid, and 7.5 g of a composite catalyst in sequence. After the addition, start stirring to control the condensation reaction temperature The temperature is about 135-145°C, and the condensation reaction is carried out by stirring for 7-13h, and the excess propionic acid is distilled off, and the temperature continues to rise until the gas begins to escape at 275°C, and the decarboxylation reaction is carried out at the temperature of 275-285°C. Use 95% ethanol solution to absorb the escaped gas and the distilled liquid. After 1-2h, there is no liquid distilled out in the four-necked reaction bottle, then stop the reaction, then cool and crystallize to obtain the p-methoxypropiophenone product. The yield of methoxypropiophenone reaches 71.05%, and the melting point is 27-28°C.

Embodiment 3

[0023] In a four-necked reaction flask equipped with an electric stirrer, a reflux condenser, and a thermometer, add 15.2 g of p-methoxybenzoic acid, 59.2 g of propionic acid, and 7.5 g of a composite catalyst in sequence. After the addition, start stirring to control the condensation reaction temperature The temperature is about 135-145°C, and the condensation reaction is carried out by stirring for 7-13h, and the excess propionic acid is distilled off, and the temperature continues to rise until the gas begins to escape at 275°C, and the decarboxylation reaction is carried out at the temperature of 275-285°C. Use 95% ethanol solution to absorb the escaped gas and the distilled liquid. After 1-2h, there is no liquid distilled out in the four-necked reaction bottle, then stop the reaction, then cool and crystallize to obtain the p-methoxypropiophenone product. The yield of methoxypropiophenone reaches 71.68%, and the melting point is 27-28°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com