High generation tablet personal computer ITO etching solution

A technology for generation of flat plates and etching solutions, applied in surface etching compositions, chemical instruments and methods, etc., can solve the problems of unstable pH value of etching solution, large amount of side etching, and large influence of ITO film etching degree, etc. The edge of the line is clear without side erosion, and the effect of improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

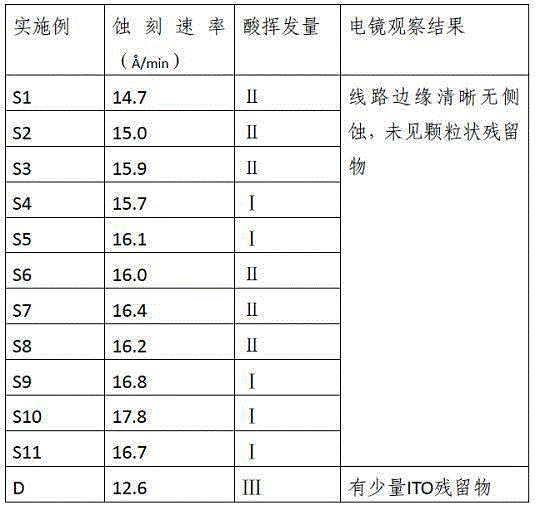

Examples

Embodiment 1

[0032] Embodiment 1 (abbreviated as S1, the same below) ITO etchant components for high-generation flat plates include: 4% by weight of sulfuric acid; 22% by weight of nitric acid; 10% by weight of acetic acid; 0.01% of additives; amount of water;

[0033] The additive is an anionic gemini surfactant, and the anionic gemini surfactant is a phosphate type gemini surfactant, specifically sodium salt of didodecyloxybisphosphate.

Embodiment 2

[0035] The difference between embodiment 2 and embodiment 1 is: the sulfuric acid of 16% by weight; The nitric acid of 7% by weight; The acetic acid of 0.1% by weight; The additive of 1%; The water of balance.

Embodiment 3

[0037] The difference between embodiment 3 and embodiment 1 is: the sulfuric acid of 9% by weight; The nitric acid of 15% by weight; The acetic acid of 5% by weight; The additive of 0.5%; The water of balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com