Additive for acidic etching solution and the acidic etching solution

An acid etching solution and additive technology, which is applied in the field of acid etching solution additives and acid etching solution, can solve the problems of thick etching speed and the like, and achieve the effects of fast etching speed, improving etching speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better explain the present invention, it is further described in conjunction with the following specific examples, but the present invention is not limited to the specific examples.

[0038] The etchant that does not use a strong oxidant, the etchant disclosed in patent CN201310557796 is used as a comparative example, and at the same time, it is used as an etchant base liquid that includes: hydrochloric acid 4.0N, chloride ions 210g / L, and ammonium ions 34g / L, and this base liquid is added with this The additives described in the patent are used as examples.

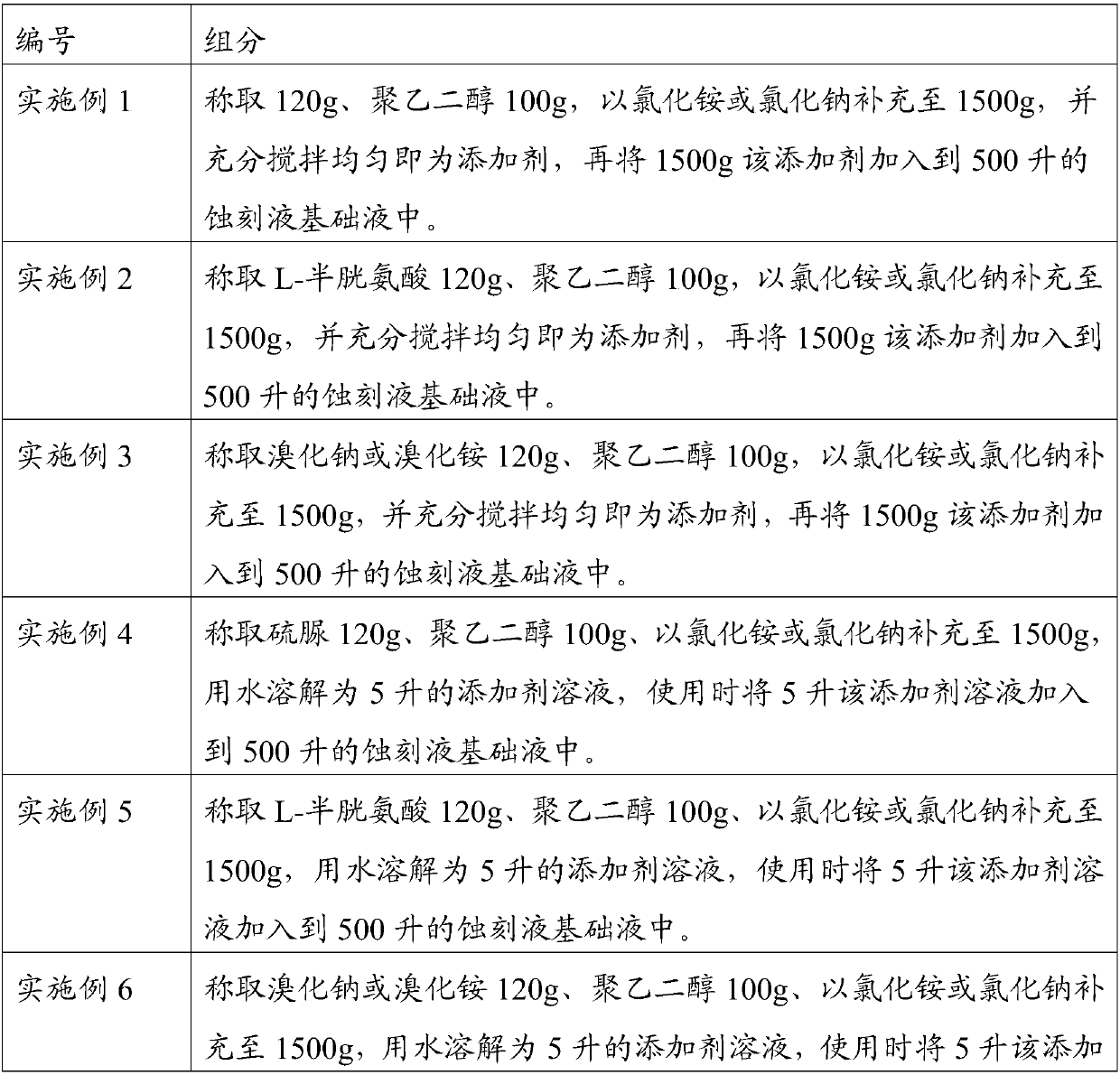

[0039] Prepare the acid etching solution according to the components given in Table 1.

[0040] Table 1:

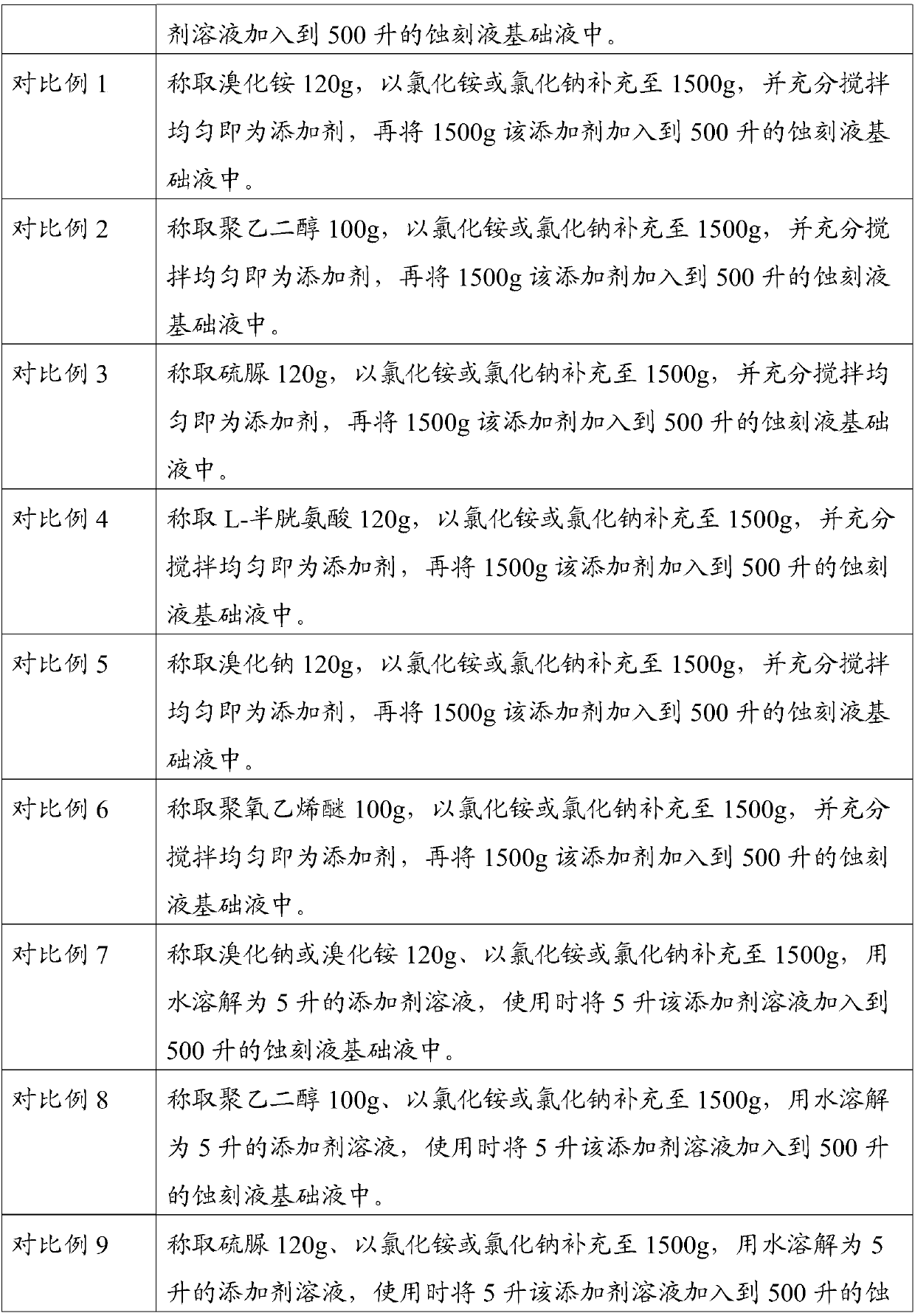

[0041]

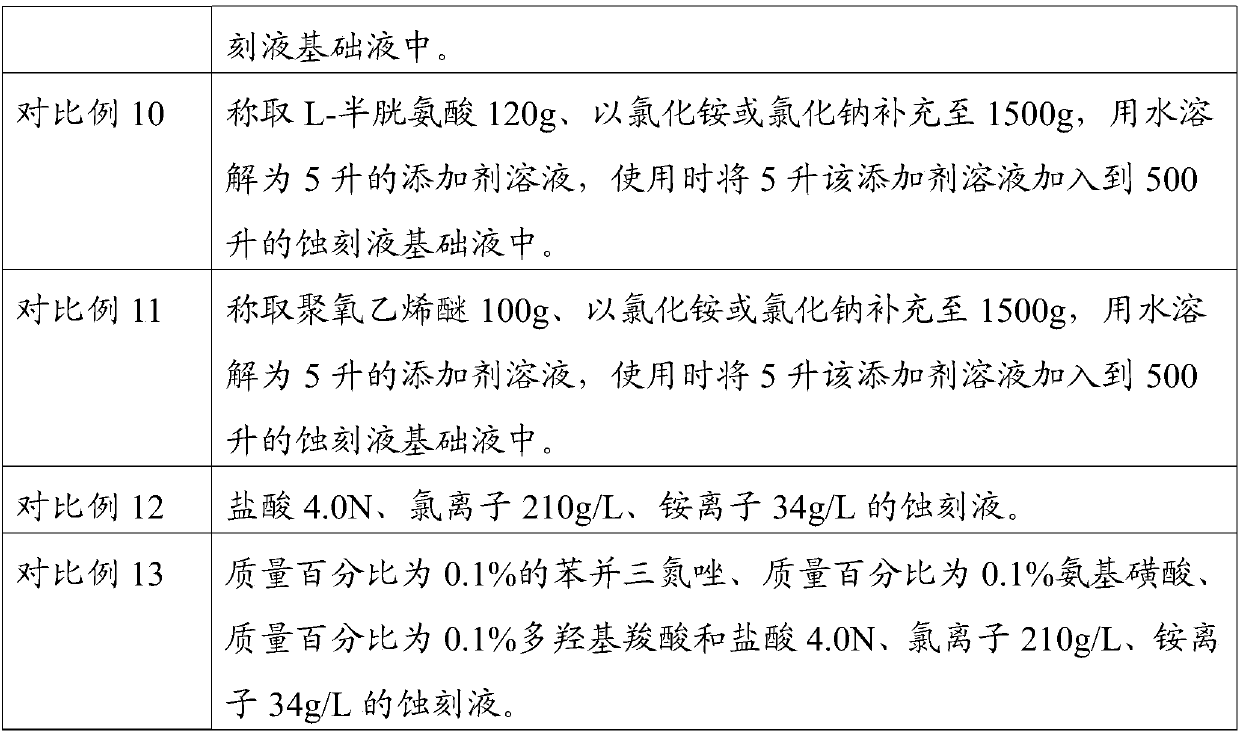

[0042]

[0043]

[0044] During production, the etching solution is continuously added into the etching working solution under the control of a pH meter or a hydrometer to keep the etching working solution stable. The additive can be directly dissolved in the etching solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com