Method for transferring Si-based AlGaN/GaN high electron mobility transistor to flexible substrate

A high electron mobility, flexible substrate technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of slow etching speed and the inability of devices to be used in flexible microelectronic devices, so as to reduce the cost of device transfer and benefit Large-scale flexible semiconductor device production, the effect of thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The present invention will be described in further detail below in conjunction with specific examples, which are further explanations of the present invention rather than limitations.

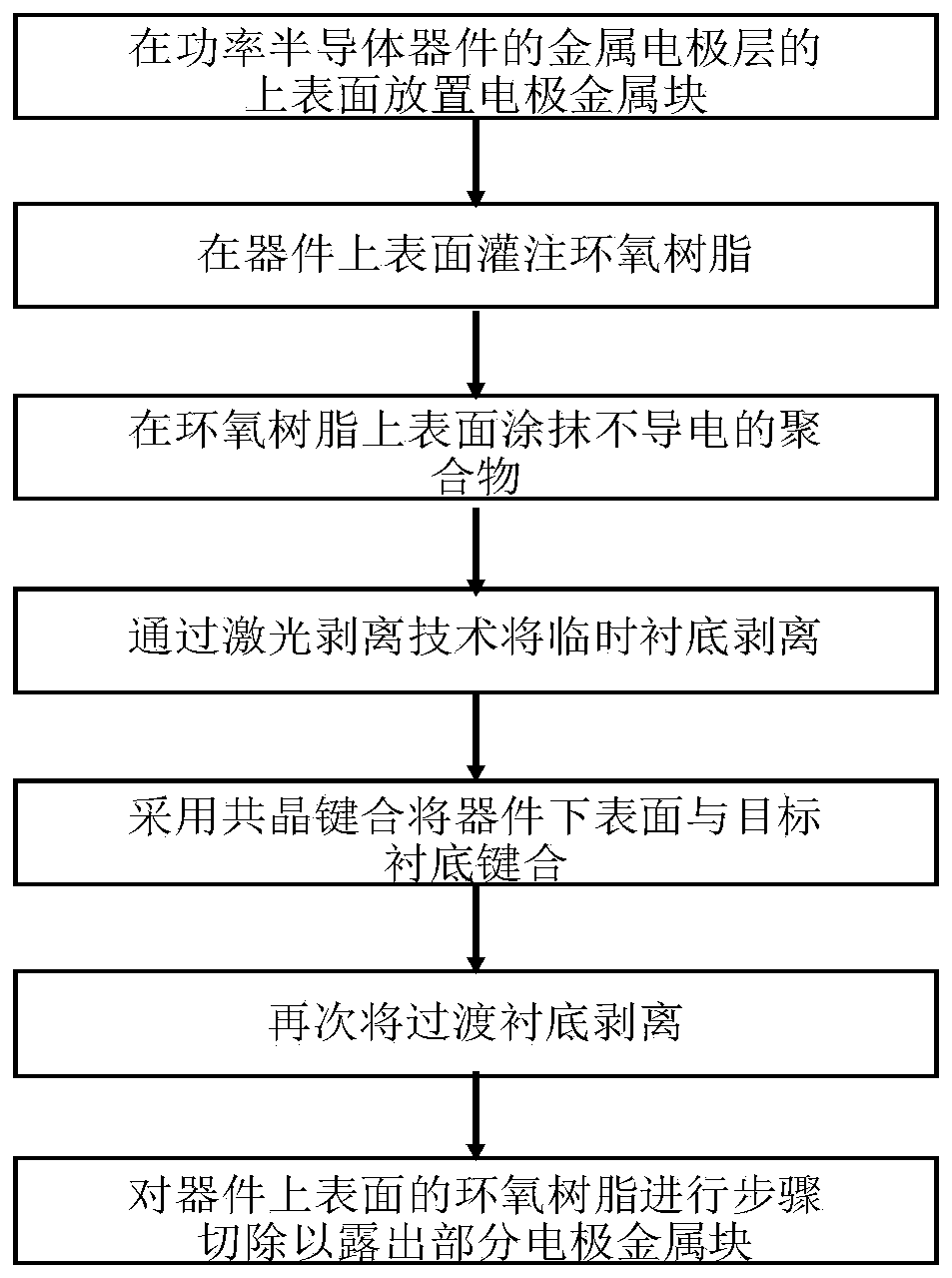

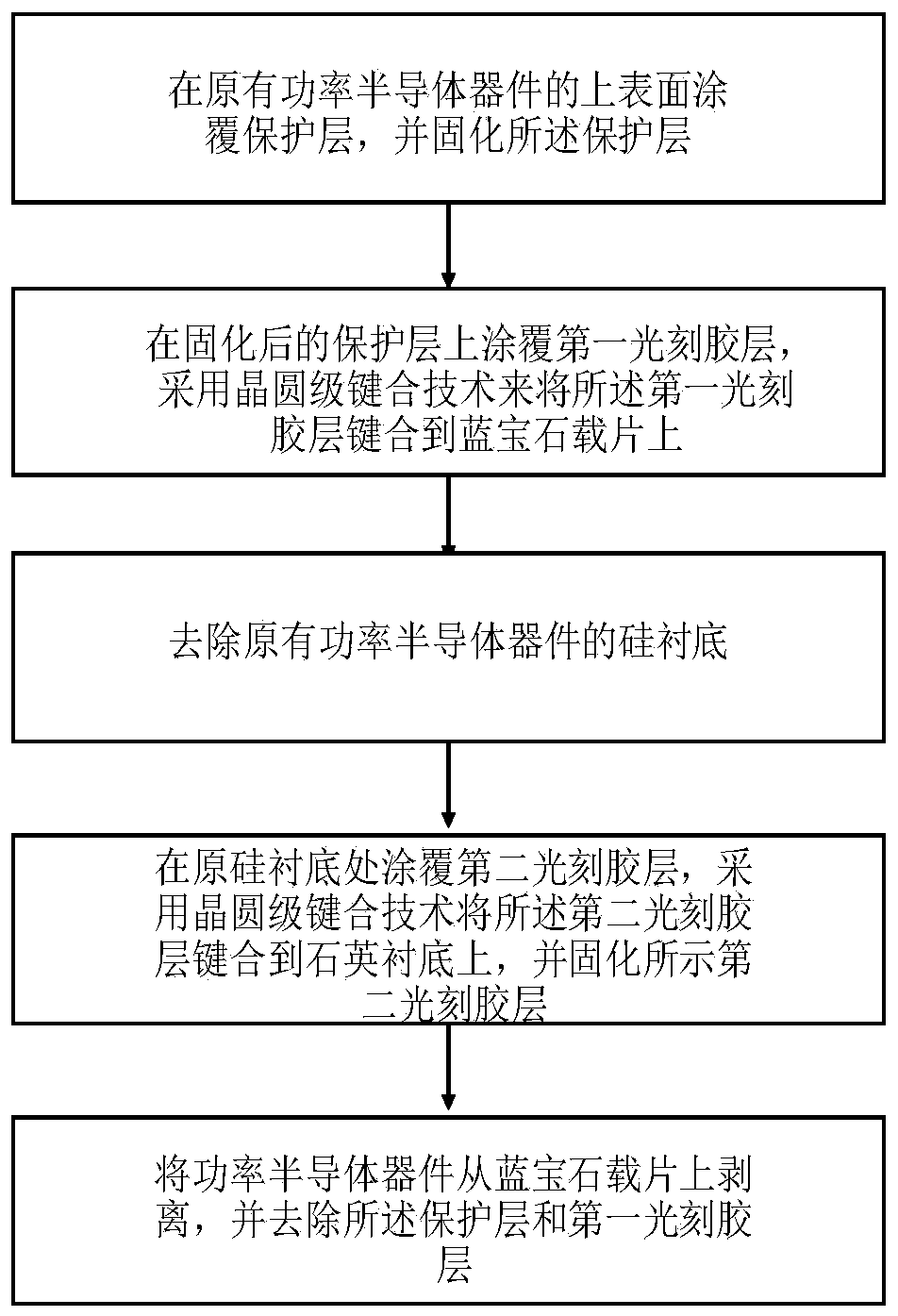

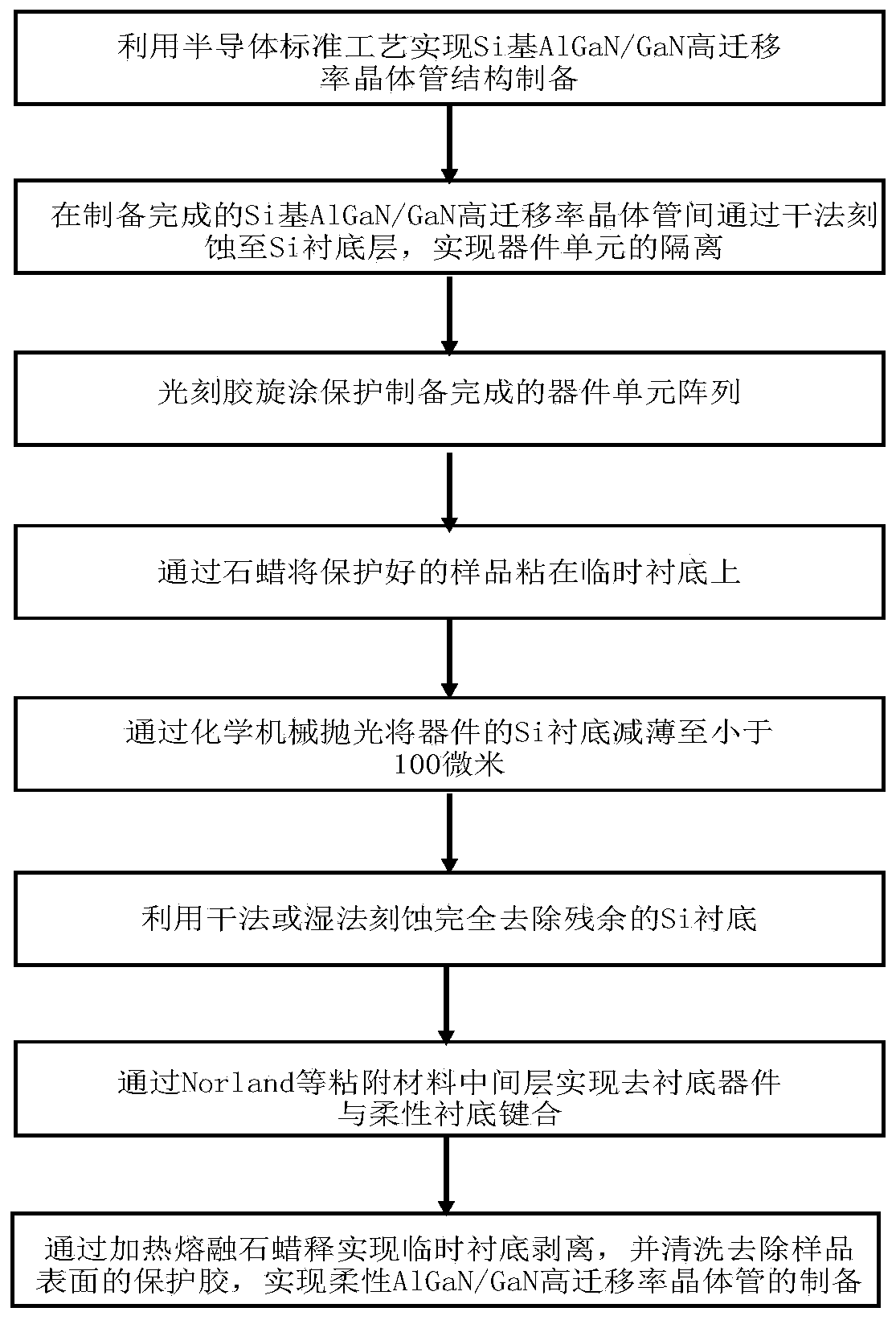

[0049] The invention provides a method for fabricating a Si-based AlGaN / GaN high electron mobility transistor and realizing a flexible substrate, which specifically includes the following steps.

[0050] Step 1: The thickness of the Si substrate 100 is 800 microns, the thickness of the GaN high-resistance buffer layer 110 is 3.5 microns, the thickness of the GaN layer 120 is 100 nm, the thickness of the AlGaN layer 130 is 20 nm, and the Al composition is 0.25. 20nm SiN grown by LPCVD X The thin film 200 is used as the gate dielectric of the device, and the source-drain ohmic contact electrode 210 of the device is made of four metal combinations of Ti / Al / Ni / Au, and then heated at 870°C and N 2 Rapid annealing under atmosphere for 30 seconds, the gate metal 220 uses Ni / Au electrodes.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com