Automatic labeling machine

A labeling machine and labeling technology, which is applied in the direction of labeling machines, labels, packaging, etc., can solve the problems of high error rate in manual labeling, reduce production efficiency, and waste time, so as to save manual handling, improve work efficiency, and save money. The effect of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

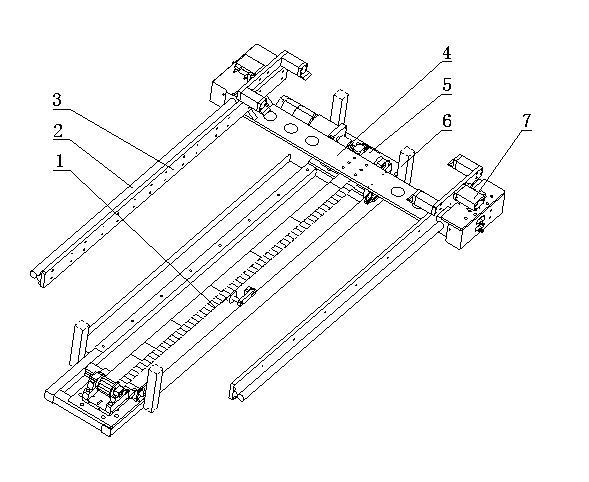

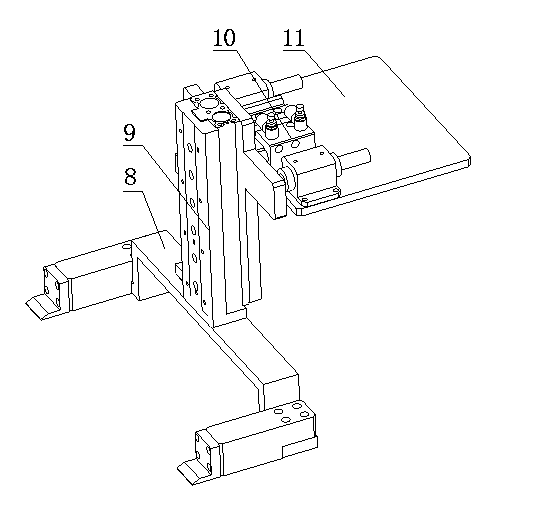

[0035] Such as Figure 1 to Figure 4 As shown, an automatic labeling machine includes a mounting frame, and is arranged on the mounting frame:

[0036] The first transfer mechanism is used to transfer the material 23;

[0037] The second transfer mechanism 22 is used for fixing and transferring materials 23;

[0038] A material identification mechanism for identifying the material 23;

[0039] Label stripping device 21, including four label stripper units, used for stripping and continuous operation of multiple labels;

[0040] The controller, whose signal input end is connected to the material 23 identification mechanism, and whose electrical signal output end is respectively electrically connected to the first transfer mechanism, the second transfer mechanism 22 and the label stripping device 21, is used to receive the material 23 identification mechanism to read label information, and control the first transfer mechanism, the second transfer mechanism 22 and the label st...

Embodiment 2

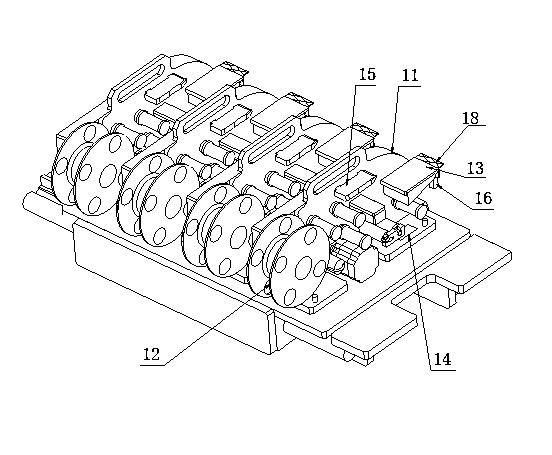

[0058] Such as Figure 5 As shown, as a preferred embodiment, the rest are the same as in Embodiment 1, except that the label stripping device includes thirty-six label stripper units, which are divided into nine groups, and each group is provided with four label stripper units, wherein , the label stripping mechanism is also provided with thirty-six vacuum suction cups 17, the vacuum suction cups 17 are integrally formed with the label stripping knife plate 13, there is a gap between the label stripping knife plate 13 and the seating plate 18, and the setting height of the seating plate 18 is It is the same as the setting height of the label stripping knife plate 13. Wherein, the vacuum suction cup 17 sucks the label and is used to fix its position to prevent the phenomenon of displacement.

[0059] The material identification mechanism provided in this embodiment is a barcode reader, the first horizontal driving device includes a servo motor and a synchronous belt 1 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com