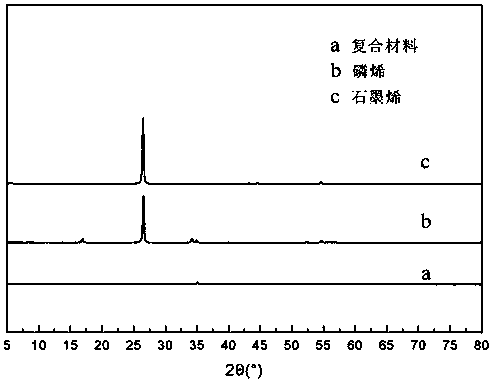

Preparation method of phosphoene-graphene composite material

A composite material, graphene technology, applied in the field of composite materials, can solve the problem of difficult to solve the problem of phosphorene stability, not suitable for large-scale preparation, difficult to continuous preparation and other problems, to achieve high stability, good electrical conductivity, equipment less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

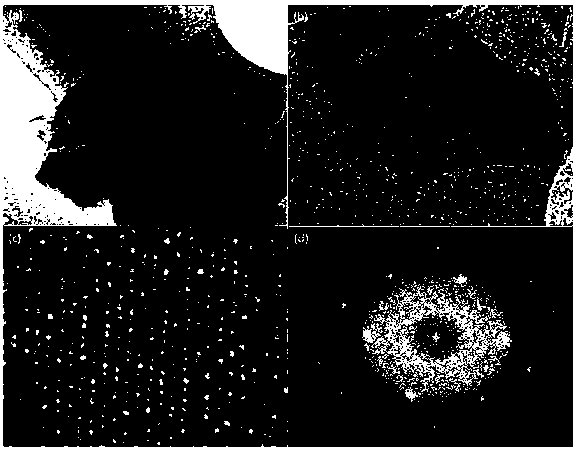

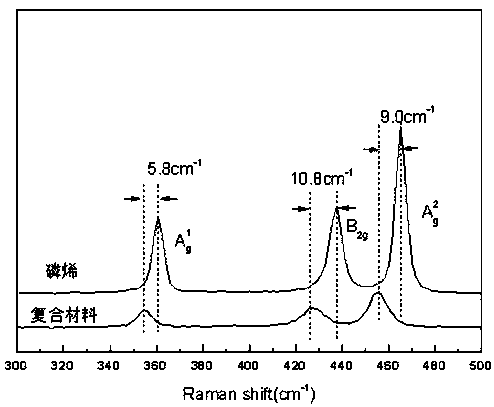

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of phosphorene-graphene composite material, concrete steps are as follows:

[0027] (1) Grind 100mg of flaky black phosphorus and 100mg of flaky graphite into powder respectively, add them to 200mL solvent (the solvent is deionized water) and mix evenly to obtain a mixed solution A; the mass ratio of flaky black phosphorus to flaky graphite 1:1;

[0028] (2) Ultrasonic pretreatment of the mixture A obtained in step (1) for 0.5h; wherein the ultrasonic power is 300W;

[0029] (3) Evacuate the air in the high-pressure homogenizer with inert gas, place the mixed liquid A pretreated by ultrasonic in step (2) in the high-pressure homogenizer, and carry out high-pressure homogenization treatment at a pressure of 1000bar for 5 minutes to obtain a suspension liquid;

[0030] (4) Centrifuge the suspension obtained in step (3) to obtain the precipitate and supernatant; wherein the centrifugation rate is 1000rpm, and the centrifugation ...

Embodiment 2

[0037] Embodiment 2: a kind of preparation method of phosphorene-graphene composite material, concrete steps are as follows:

[0038] (1) Grind 100mg of flaky black phosphorus and 200mg of flaky graphite into powder, add them to 200mL solvent (the solvent is deionized water) and mix evenly to obtain a mixed solution A; the mass ratio of flaky black phosphorus to flaky graphite is 0.5:1;

[0039] (2) Ultrasonic pretreatment of the mixture A obtained in step (1) for 1 hour; wherein the ultrasonic power is 200W;

[0040] (3) Evacuate the air in the high-pressure homogenizer with inert gas, put the mixed liquid A pretreated by ultrasonic in step (2) in the high-pressure homogenizer, and perform high-pressure homogenization treatment for 30 minutes under the pressure of 1000bar to obtain a suspension liquid;

[0041] (4) Centrifuge the suspension obtained in step (3) to obtain the precipitate and supernatant; wherein the centrifugation rate is 3000rpm, and the centrifugation time...

Embodiment 3

[0044] Embodiment 3: a kind of preparation method of phosphorene-graphene composite material, concrete steps are as follows:

[0045] (1) Grind 200mg of flaky black phosphorus and 400mg of flaky graphite into powder respectively, add them to 300mL solvent (the solvent is deionized water) and mix evenly to obtain a mixed solution A; the mass ratio of flaky black phosphorus to flaky graphite is 0.5:1;

[0046](2) Ultrasonic pretreatment of the mixture A obtained in step (1) for 2 hours; wherein the ultrasonic power is 100W;

[0047] (3) Evacuate the air in the high-pressure homogenizer with inert gas, place the mixed liquid A pretreated by ultrasonic in step (2) in the high-pressure homogenizer, and perform high-pressure homogenization treatment for 60 minutes at a pressure of 4000 bar to obtain a suspension liquid;

[0048] (4) Centrifuge the suspension obtained in step (3) to obtain the precipitate and supernatant; wherein the centrifugation rate is 10000rpm, and the centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com