Montmorillonite/graphene oxide composite nanosheet layer material modified epoxy resin anticorrosive paint as well as preparation method and application thereof

A graphene composite and epoxy resin technology, applied in the field of material science, can solve the problems of lack of chemical combination and inconspicuous synergistic effect, and achieve good corrosion protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

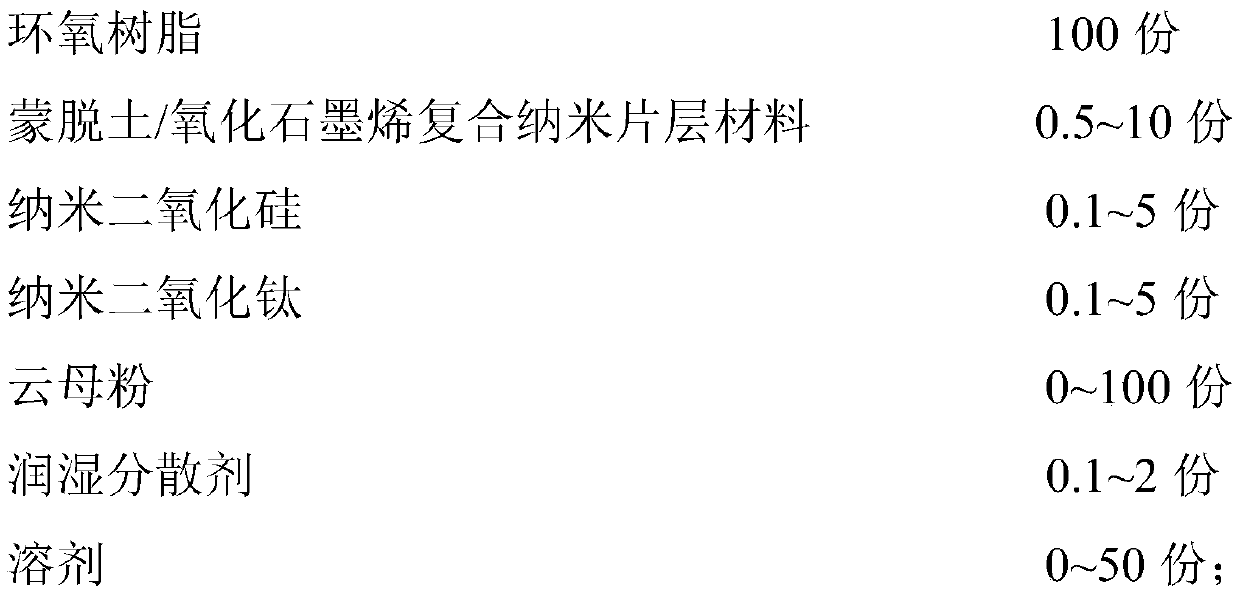

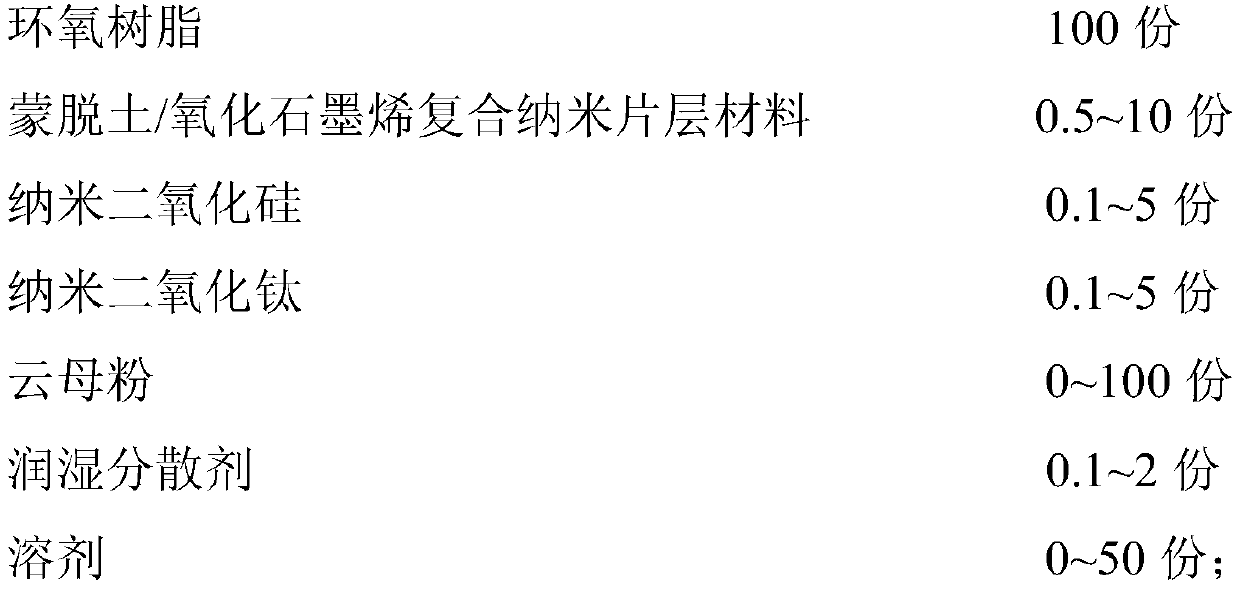

Method used

Image

Examples

Embodiment 1

[0052] (1) Preparation of dispersion of organic amine-modified graphene oxide

[0053] Weigh 0.3 g of graphene oxide, add it into 200 g of methyl ethyl ketone, and undergo ultrasound for 6 hours to obtain a graphene oxide dispersion. Weigh 3 g of 1,10-decanediamine and dissolve it in 100 g of butanone to obtain a 1,10-decanediamine solution. Add the 1,10-decanediamine solution into the graphene oxide dispersion under the condition of 75°C and 350rpm mechanical stirring. Insulated for 5 hours to obtain a 1,10-decanediamine-modified graphene oxide dispersion. After the system is cooled, the product is centrifuged and washed to obtain 1,10-decanediamine-modified graphene oxide.

[0054] (2) Preparation of montmorillonite / graphene oxide composite nanosheet materials

[0055] Disperse the 1,10-decanediamine-modified graphene oxide obtained in step (1) in 100 g of butanone, add 30 mL of 1mol / L hydrochloric acid solution for protonation, and obtain protonated 1,10-decanediamine-mo...

Embodiment 2

[0070] (1) Preparation of dispersion of organic amine-modified graphene oxide

[0071] Weigh 0.2 g of graphene oxide, add it into 150 g of dioxane, and undergo ultrasound for 5 hours to obtain a graphene oxide dispersion. Weigh 10 g of diaminodiphenylmethane and dissolve in 50 g of dioxane to obtain a diaminodiphenylmethane solution. Add the diaminodiphenylmethane solution into the graphene oxide dispersion under the condition of 80° C. and 550 rpm mechanical stirring. Insulated for 6 hours to obtain a diaminodiphenylmethane-modified graphene oxide dispersion. After the system is cooled, it is centrifuged and washed to obtain diaminodiphenylmethane-modified graphene oxide.

[0072] (2) Preparation of montmorillonite / graphene oxide composite nanosheet materials

[0073] The diaminodiphenylmethane-modified graphene oxide obtained in step (1) is dispersed in 120g of dioxane, and hydrochloric acid solution is added for protonation to obtain protonated diaminodiphenylmethane-mod...

Embodiment 3

[0088] (1) Preparation of dispersion of organic amine-modified graphene oxide

[0089] Weigh 0.5 g of graphene oxide, add it into 1000 g of deionized water, and undergo ultrasound for 9 hours to obtain a graphene oxide aqueous dispersion. 25g of tetraethylenepentamine was weighed and dissolved in 100g of deionized water to obtain an aqueous solution of tetraethylenepentamine. Under the condition of 85° C. and 700 rpm mechanical stirring, the tetraethylenepentamine solution was added to the graphene oxide aqueous dispersion. The heat preservation reaction was carried out for 8 hours to obtain a tetraethylenepentamine-modified graphene oxide dispersion. After the system is cooled, it is centrifuged and washed to obtain tetraethylenepentamine-modified graphene oxide.

[0090] (2) Preparation of montmorillonite / graphene oxide composite nanosheet materials

[0091]Disperse the tetraethylenepentamine-modified graphene oxide obtained in step (1) in 1000g deionized water, add hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com