Magnesium alloy surface composite coating and preparation method thereof

A surface composite, magnesium alloy technology, applied in the direction of surface reaction electrolytic coating, metal material coating process, coating, etc., can solve the problems of affecting fatigue wear life, corrosion and degradation of parts by diffusion of corrosive medium matrix interface, etc. The effect of load carrying capacity and friction and wear resistance, inhibition of galvanic corrosion, good reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a composite coating on a magnesium alloy surface, characterized in that it comprises the steps of:

[0037] 1) Grind and polish the sample with metallographic sandpaper to remove surface oxides and pollutants, clean the sample ultrasonically with alcohol for 10 minutes, and then dry it for later use;

[0038] 2) Before spraying, the sample needs to be sandblasted, and the sandblasting particle size is 30 mesh;

[0039] 3) The metal aluminum layer adopts low-pressure supersonic spraying equipment, which does not need to melt the sprayed metal particles, and the temperature generated on the surface of the sprayed substrate does not exceed 150°C;

[0040] The main spraying parameters are as follows: the particle size of aluminum powder is 200-400 mesh, the voltage is 220V, and the pressure is 0.7Pa-0.9Pa.

[0041] 4) Use micro-arc oxidation technology to in-situ grow micro-arc oxidation ceramic coating on the surface of aluminum metal layer. The pre...

Embodiment 1

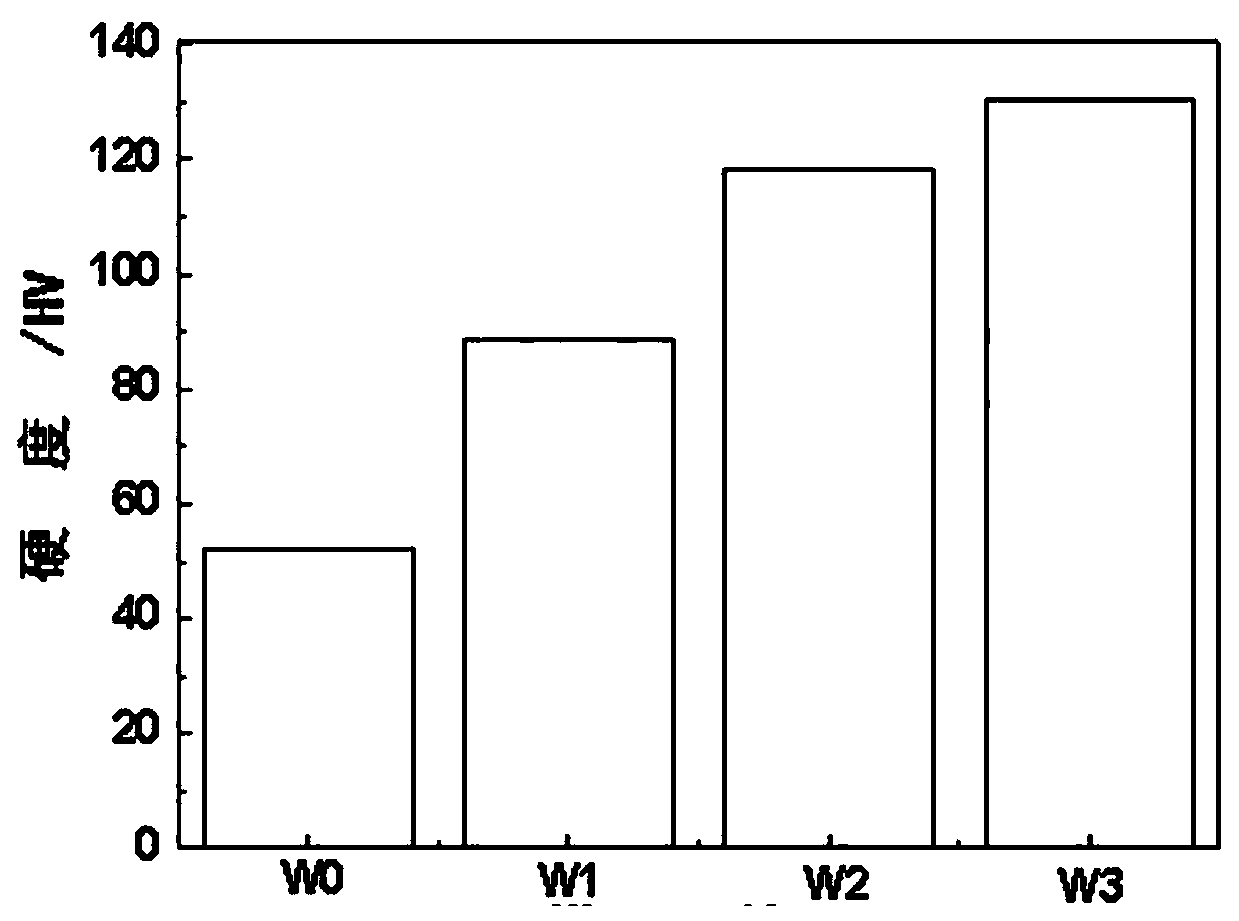

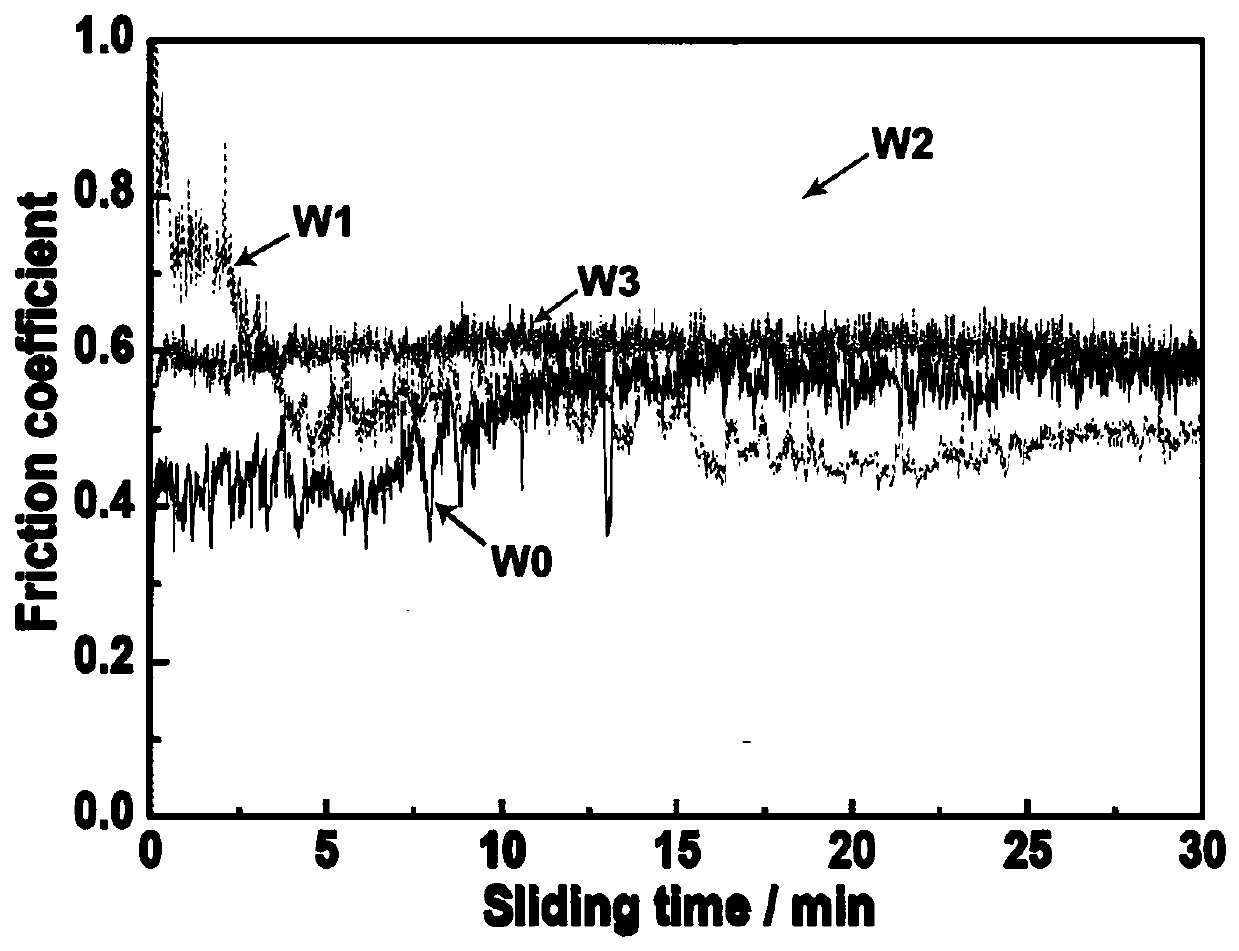

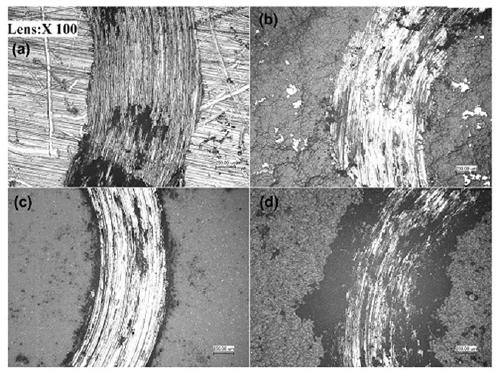

[0043] The following examples will disclose a gradient composite coating on the surface of a magnesium alloy, including a bottom cold-sprayed intermediate layer as a corrosion medium barrier and a stress buffer zone. The surface is grown in-situ on the intermediate layer by micro-arc oxidation technology with high chemical inertness and mechanical properties. Ceramic coating for strong wear and corrosion protection.

[0044]As a preferred option of the graded composite coating on the surface of the magnesium alloy of the present invention, the bottom middle layer is a cold-sprayed pure metal aluminum layer with a thickness of 300 μm-500 μm.

[0045] As a preferred option of the graded composite coating on the surface of the magnesium alloy of the present invention, the surface carrying layer is a micro-arc oxidation layer with a thickness of 8 μm-12 μm.

[0046] The method for preparing the gradient composite coating on the surface of magnesium alloy in this embodiment compris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com