Aqueous graphene high-thermal-conductivity anticorrosive coating material for power batteries, and preparation method thereof

A technology for power batteries and anti-corrosion coatings, applied in anti-corrosion coatings, heat exchange materials, epoxy resin coatings, etc., can solve the problems of reduced use stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

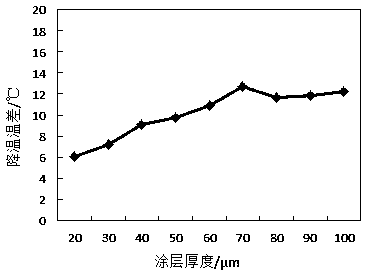

Image

Examples

Embodiment 1

[0023] A water-based graphene high thermal conductivity anticorrosion coating for a power battery is characterized in that it is a two-component coating, including a component and a component B, and the mass ratio of the component A and component B is 4:1, by weight Number, group A includes 30 parts of water-based epoxy resin, 10 parts of water-based silicone resin, 5 parts of graphene powder, 13 parts of silicon carbide, 22 parts of mica powder, 1 part of fumed silica, and 1 part of silicone defoaming agent, 18 parts deionized water, Part B includes 50 parts water-based epoxy curing agent and 50 parts deionized water.

[0024] A method for preparing a water-based graphene high thermal conductivity anticorrosion coating for a power battery comprises the following steps.

[0025] (1) In parts by weight, first weigh 30 parts of water-based epoxy resin and 10 parts of water-based silicone resin and place them in a dispersion tank, then add 5 parts of graphene powder, 1 part of fu...

Embodiment 2

[0032] A water-based graphene high thermal conductivity anticorrosion coating for a power battery is characterized in that it is a two-component coating, comprising a component and a component B, and the mass ratio of the component A and component B is 5:1, in parts by weight Number, component A includes 30 parts of water-based epoxy resin, 8 parts of water-based silicone resin, 7 parts of graphene powder, 15 parts of silicon carbide, 20 parts of glass flakes, 1 part of fumed silica, 2 parts of silicone defoaming agent, 17 parts deionized water, Part B includes 55 parts water-based epoxy curing agent and 45 parts deionized water.

[0033] A method for preparing a water-based graphene high thermal conductivity anticorrosion coating for a power battery comprises the following steps.

[0034] (1) In parts by weight, first weigh 30 parts of water-based epoxy resin and 8 parts of water-based silicone resin and place them in a dispersion tank, then add 7 parts of graphene powder, 1 ...

Embodiment 3

[0041] A water-based graphene high thermal conductivity anti-corrosion coating for power batteries is a two-component coating, including component A and component B, the mass ratio of component A and component B is 6:1, in parts by weight, Component A includes 27 parts of water-based epoxy resin, 10 parts of water-based silicone resin, 10 parts of graphene powder, 15 parts of alumina, 17 parts of micaceous iron oxide ash, 1 part of magnesium lithium silicate, and 1 part of water-based mineral oil emulsion , 19 parts of deionized water, component B includes 60 parts of water-based epoxy curing agent and 40 parts of deionized water.

[0042]A method for preparing a water-based graphene high thermal conductivity anticorrosion coating for a power battery comprises the following steps.

[0043] (1) In parts by weight, first weigh 27 parts of water-based epoxy resin and 10 parts of water-based silicone resin and place them in a dispersion tank, then add 10 parts of graphene powder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com