Environment-friendly type long-life engine coolant

An engine coolant, long-life technology, applied in the field of engine coolant, can solve the problems of poor thermal stability of silicate, prolong life, not environmentally friendly, etc., to improve the corrosion protection effect, solve the obvious drop in pH value, improve Environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

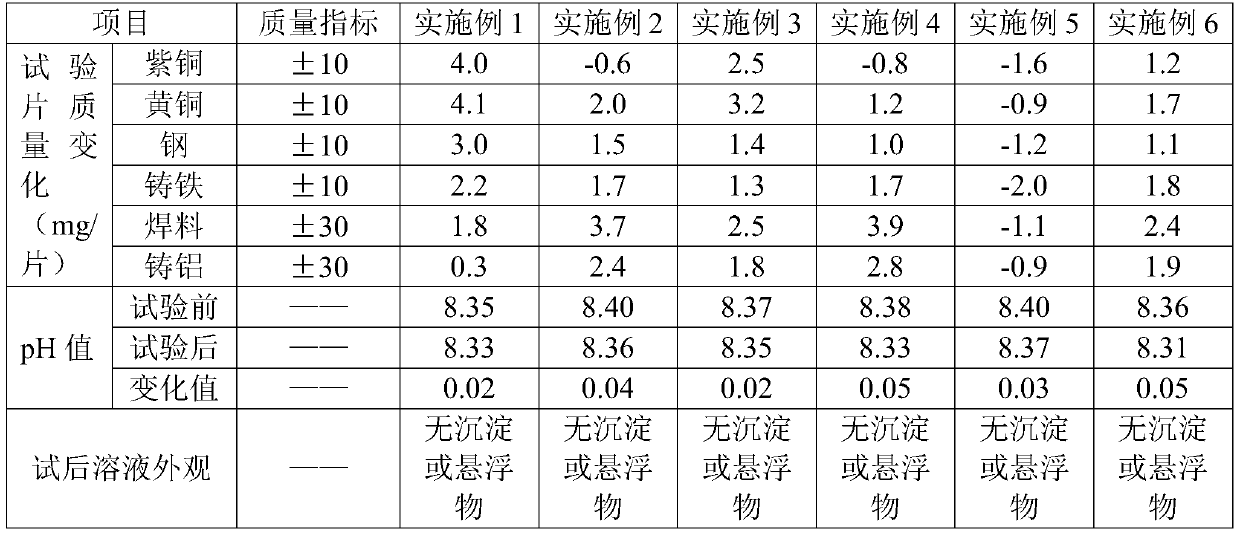

Examples

Embodiment 1

[0021] An environment-friendly long-life engine coolant, comprising the following raw material components in parts by weight: 50 parts of deionized water, 50 parts of ethylene glycol, 0.02 parts of sodium hydroxide, 0.02 parts of potassium hydroxide, 0.1 part of isooctanoic acid, and 0.2 parts of nonanoic acid, 0.3 parts of neodecanoic acid, 0.1 parts of sebacic acid, 0.05 parts of undecanoic acid, 0.05 parts of dodecanedioic acid, 0.1 parts of triazine triaminocaproic acid, 0.07 parts of glutamic acid, N- 0.03 part of octanoyl glutamic acid, 0.1 part of sulfosiloxane, 0.1 part of methyl benzotriazole, 0.005 part of emulsified silicone oil defoamer, and 0.005 part of dye.

Embodiment 2

[0023] An environment-friendly long-life engine coolant, comprising the following raw material components in parts by weight: 50 parts of deionized water, 50 parts of ethylene glycol, 0.3 part of sodium hydroxide, 0.2 part of potassium hydroxide, 0.2 part of isooctanoic acid, 0.2 part of isocaprylic acid, 0.2 parts of nonanoic acid, 0.7 parts of neodecanoic acid, 0.7 parts of sebacic acid, 0.3 parts of undecanoic acid, 0.3 parts of dodecanoic diacid, 0.5 parts of triazine triaminocaproic acid, 0.2 parts of glutamic acid, N- 0.2 part of octanoyl glutamic acid, 0.4 part of sulfosiloxane, 0.2 part of methyl benzotriazole, 0.01 part of emulsified silicone oil defoamer, and 0.01 part of dye.

Embodiment 3

[0025] An environment-friendly long-life engine coolant, comprising the following raw material components in parts by weight: 50 parts of deionized water, 50 parts of ethylene glycol, 0.15 parts of sodium hydroxide, 0.15 parts of potassium hydroxide, 0.15 parts of isooctanoic acid, 0.2 parts of nonanoic acid, 0.5 parts of neodecanoic acid, 0.4 parts of sebacic acid, 0.2 parts of undecanoic acid, 0.2 parts of dodecanedioic acid, 0.3 parts of triazine triaminocaproic acid, 0.15 parts of glutamic acid, N- 0.1 part of octanoyl glutamic acid, 0.25 part of sulfosiloxane, 0.15 part of methyl benzotriazole, 0.005 part of emulsified silicone oil defoamer, and 0.005 part of dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com