Water-based ceramic coating and preparation method thereof

A ceramic coating, water-based technology, applied in the direction of anti-corrosion coatings, fire-resistant coatings, polyurea/polyurethane coatings, etc., can solve the problems of shortened product shelf life, affecting coating efficiency, poor storage stability, etc., to improve the water vapor barrier effect and improve corrosion Protective performance, effect of reducing shrinkage stress

Active Publication Date: 2020-12-18

NANJING CHANGJIANG PAINT

View PDF10 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] (1) Poor storage stability: Since silane is prone to hydrolysis during storage, and then condenses with silica sol, pigments, and fillers to form insoluble matter, so in order to improve the stability of ceramic coatings, manufacturers can only use two-component or three-component Pack silane, silica sol, pigments and fillers in parts

At the same time, the shelf life of the product is also shorter than that of organic coatings

[0006] (2) Long curing time and short pot life: In order to obtain the ideal silanol prepolymer, promote the uniform film formation of ceramic coatings and avoid stress cracking, ceramic coatings need to be stirred and matured for a long time before application, and generally need to last for 2~ 8h; and the cured ceramic coating needs to be painted within a few hours, otherwise the product will gel and lose its performance

This cumbersome pre-mixing process puts forward higher requirements on the equipment and process control of coating companies

[0007] (3) Poor flexibility, no bending resistance, no impact resistance: Since the ceramic coating is a highly cross-linked inorganic network (hardness up to 9H), the coating is highly brittle

[0008] (4) Poor recoatability: due to the low surface energy of ceramic coatings and difficult wetting, the recoatability of the coating is poor

For unqualified products, it can only be reworked after grinding to the metal substrate, which seriously affects the coating efficiency, and it is impossible to obtain a high film thickness ceramic coating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0039] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

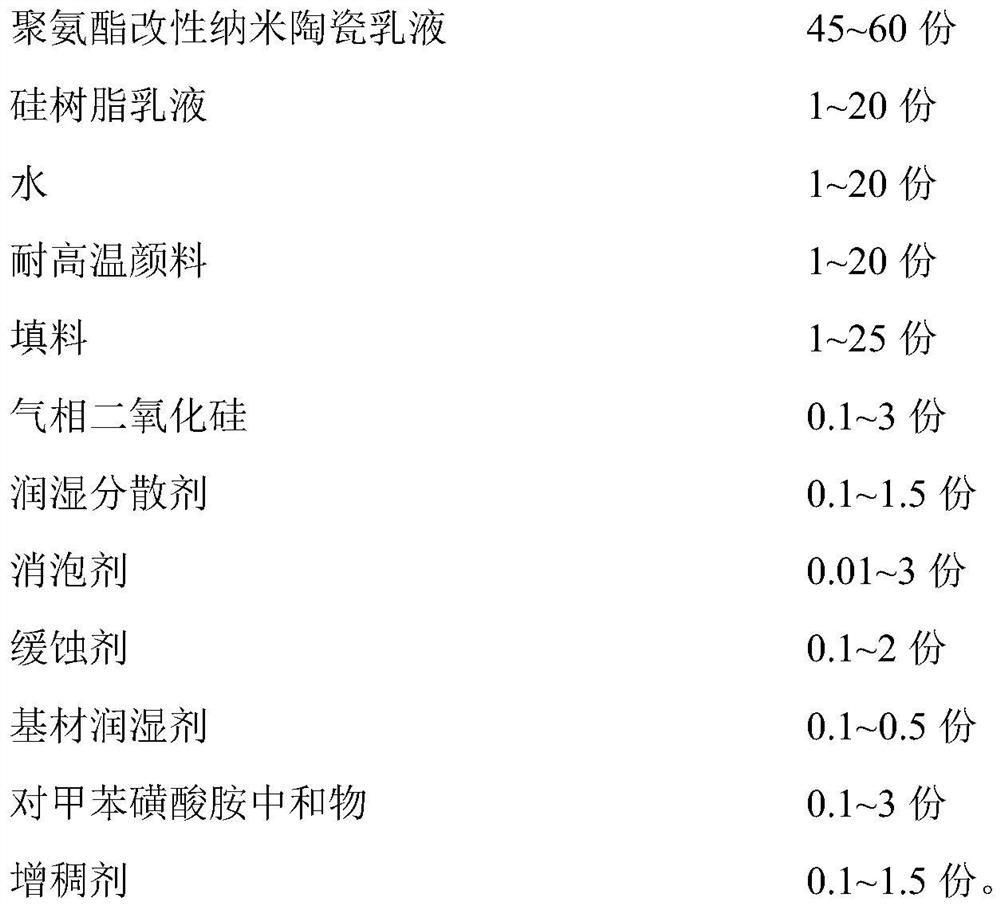

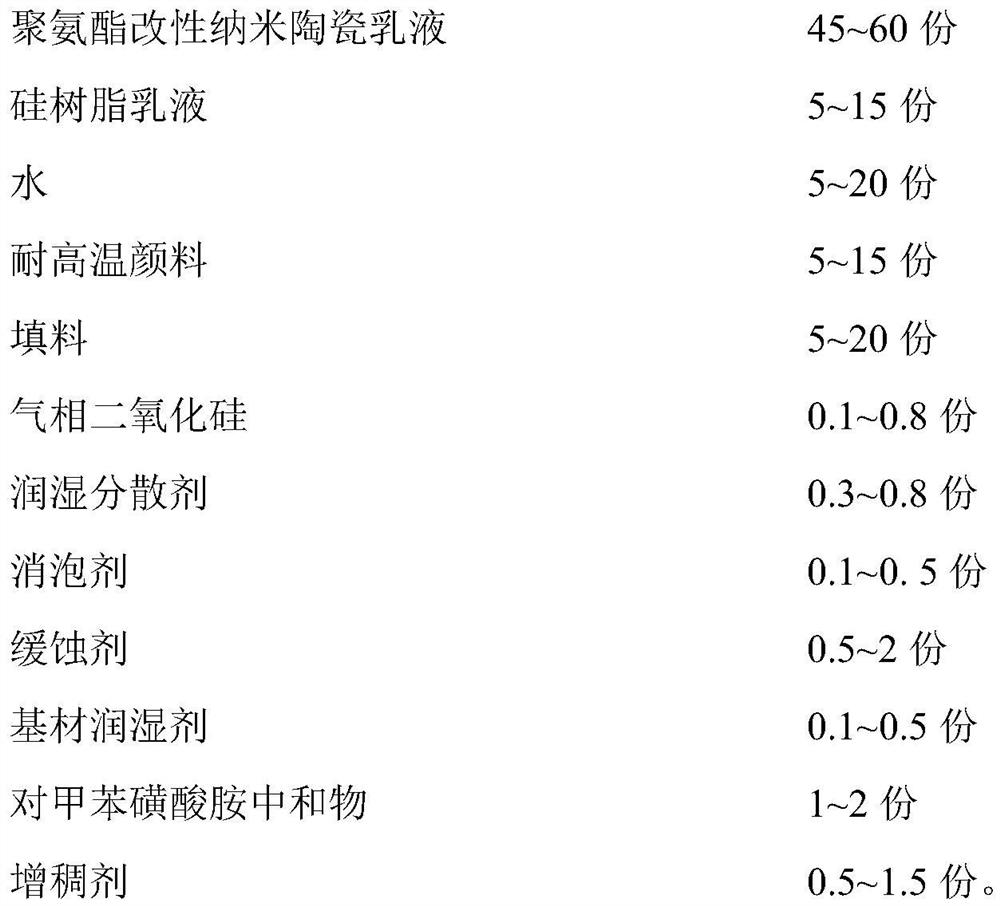

The invention discloses a high-toughness water-based ceramic coating. The coating is a water-based, single-component, baked and dried product and is prepared from polyurethane modified nano ceramic emulsion, silicon resin emulsion, a high-temperature-resistant pigment, a filler, auxiliaries, an ammonium toluene-4-sulphonate neutralizer and water. The coating is convenient to construct and extremely low in coating VOC emission, has excellent flame retardance, heat resistance, corrosion medium shielding, bending resistance and impact resistance, and is an excellent choice for high-temperature-resistance and high-durability anti-corrosion protective coating.

Description

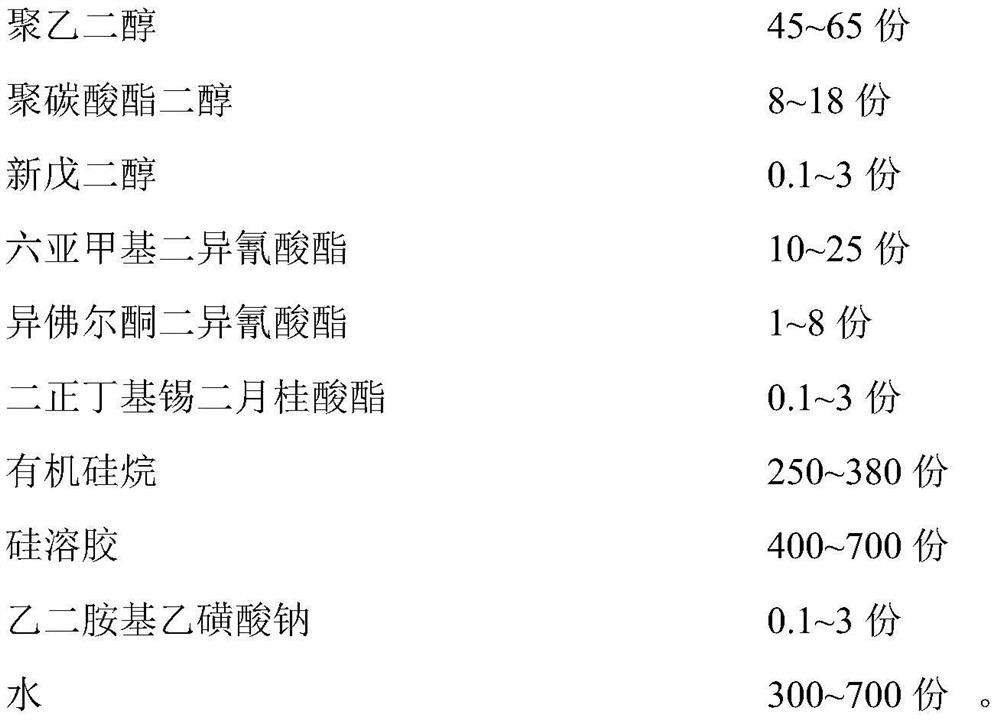

technical field [0001] The invention relates to the technical field of coatings, in particular to a water-based ceramic coating with high temperature resistance, easy recoating, good corrosive medium shielding effect and bending resistance and a preparation method thereof. Background technique [0002] Ceramic coatings are a new class of coating materials based on organic-inorganic hybrid technology. Because its main structure is a covalently cross-linked inorganic (metal oxide, non-metal oxide, etc.) network, it has many traditional organic materials such as high hardness, friction resistance, flame retardancy, super weather resistance, low surface energy, and chemical solvent resistance. The incomparable performance advantages of coatings make it an excellent choice for preparing high-temperature-resistant and high-durability special coatings. [0003] Ceramic coatings are mainly based on sol-gel technology solutions, the core components of which are silica sol and silane...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D1/00C09D183/08C09D175/04C09D183/04C09D5/18C09D5/08C09D7/20C09D7/61C09D7/63

CPCC09D1/00C09D183/08C09D5/18C09D5/08C09D7/20C09D7/61C09D7/70C09D7/63C08L2201/02C08L2201/08C08L2205/02C08L2205/03C08L75/04C08L83/04C08K13/04C08K3/36C08K3/34C08K7/10C08K5/42

Inventor 陈钊聪张卫中

Owner NANJING CHANGJIANG PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com