Preparation method for protective coating doped and modified by silicon dioxide and application of preparation method

A silicon dioxide and protective coating technology, applied in the field of metal anti-corrosion, can solve the problems of drug waste, energy consumption, many steps, etc., and achieve the effects of convenient operation, saving time and resources, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

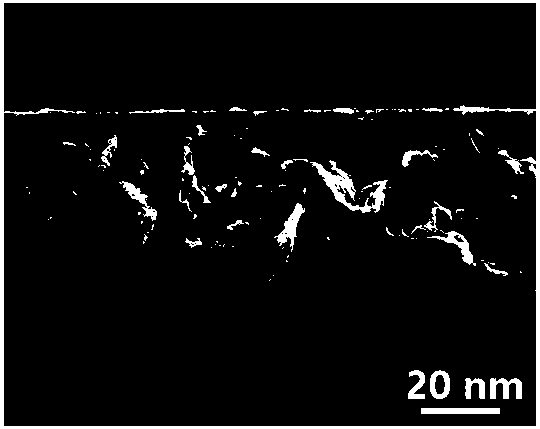

[0023] Add 100 mL of water to the jar, add sodium hydroxide to adjust the pH to 14.0, add 1.00 g of triblock copolymer F27, 1.00 g of urotropine, stir well, heat the mixed solution to 100 °C, add 10 mL of Ethyl silicate, reaction 24h. The obtained suspension is separated, and the obtained precipitate is washed with water and then dried to obtain a solid silicon dioxide powder. Add 0.01 wt% silica powder to the alkyd resin and stir well. Brush the modified paint onto the surface of the pure copper substrate. After drying and curing, a silicon dioxide-doped modified protective coating can be obtained. The cross-sectional scanning electron micrographs of the prepared silica-doped modified alkyd coating are as follows: figure 1 shown. Accelerated corrosion control experiments were performed using a pure copper substrate coated with a blank alkyd coating or a silica-doped modified alkyd coating. First, a blade is used to produce a defect of one centimeter long, 50 microns wide...

Embodiment 2

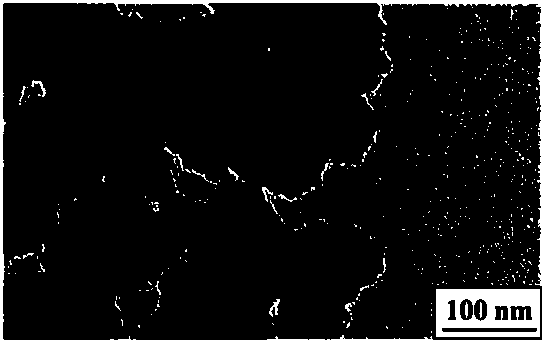

[0027] Add 25 mL of water and 75 mL of ethanol in a jar, add sodium hydroxide to adjust the pH to 9.0, add 0.05 g of triblock copolymer P123, 0.05 g of mercaptobenzothiazole, stir well, and heat the mixed solution to 25 °C. Add 0.1 mL of methyl orthosilicate and react for 0.1 h. The obtained suspension was separated, and the obtained precipitate was washed with water and then dried to obtain a solid silicon dioxide powder. The transmission electron microscope photo of it is as follows: figure 2 shown. Add 10 wt% silica powder to the alkyd resin and stir well. Dip-coat the modified coating onto the surface of a pure copper substrate. After drying and curing, a silicon dioxide-doped modified protective coating can be obtained. The corrosion protection performance evaluation is the same as in Example 1, and the experimental results are listed in Table 2.

[0028] Table 2 Corrosion test results of alkyd coating and silicon dioxide doped modified alkyd coating on pure copper s...

Embodiment 3

[0031] Add 90 mL of water and 10 mL of ethanol to the jar, add sodium hydroxide to adjust the pH to 12.0, add 1.00 g of cetyltrimethylammonium chloride, 0.50 g of benzotriazole, stir well, and mix the solution Heated to 80 °C, added 3 mL of ethyl orthosilicate, and reacted for 2 h. The obtained suspension is separated, and the obtained precipitate is washed with water and then dried to obtain a solid silicon dioxide powder. Add 1.0wt% silica powder to the alkyd resin and stir well. Brush the modified paint onto the surface of the pure copper substrate. After drying and curing, a silicon dioxide-doped modified protective coating can be obtained. Accelerated corrosion control experiments were performed using a pure copper substrate coated with a blank alkyd coating or a silica-doped modified alkyd coating. The corrosion protection performance evaluation is the same as in Example 1, and the experimental results are listed in Table 3.

[0032] Table 3 Corrosion test results of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com