Fluorine and silicone copolymerization modification amphiphilic acrylate polymer anti-corrosive paint and preparation method thereof

An anti-corrosion coating and copolymerization modification technology, applied in anti-corrosion coatings and other directions, can solve the problems of national economic loss of metal materials, environmental pollution and energy consumption, metal structure damage, etc., to achieve uniform corrosion protection performance, avoid local corrosion, and prevent corrosion. effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Anti-corrosion paint preparation method, the paint is carried out according to the following steps in 100 parts by mass:

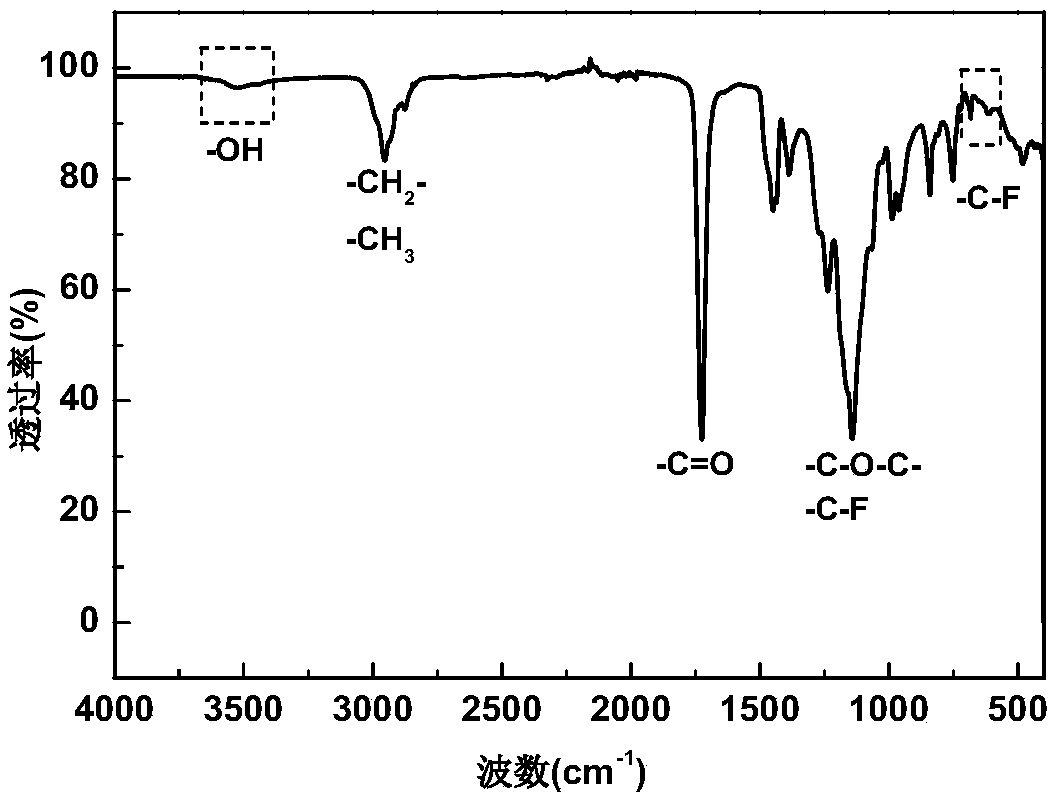

[0028] 1. Preparation of amphiphilic acrylate polymer modified by fluorosilicone copolymerization: methyl methacrylate, n-butyl acrylate, β-hydroxypropyl acrylate, hexafluorobutyl methacrylate, vinyl triethoxy Add 24.8, 12.5, 5.0, 5.0, 2.5 parts by mass of base silane into the reactor and mix evenly to obtain the mixed solution a;

[0029] The catalyst azobisethylbutyronitrile (AIBN) with a mass fraction of 0.2 is completely dissolved in butyl acetate with a mass fraction of 50.0 to obtain a mixed liquid b;

[0030] Add the mixed solution b into the mixed solution a, and stir evenly to obtain the mixed solution c.

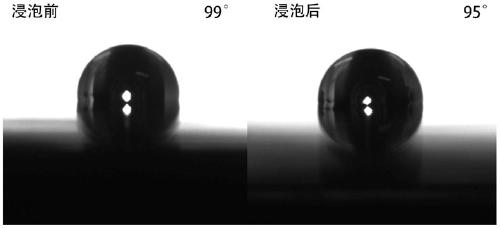

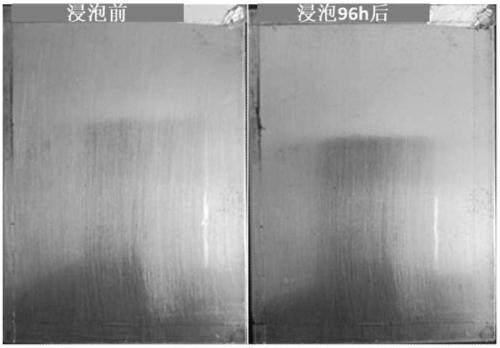

[0031] 2. Place the obtained mixed solution c in a water bath at 70°C for 24 hours, and then cool it down to room temperature to obtain the anticorrosion coating d of amphiphilic acrylate polymer modified by fluorine-silicon copolymeriz...

Embodiment 2

[0039] Anti-corrosion paint preparation method, the paint is carried out according to the following steps in 100 parts by mass:

[0040] 1. Preparation of amphiphilic acrylate polymer modified by fluorosilicone copolymerization: methyl methacrylate, n-butyl acrylate, β-hydroxypropyl acrylate, dodecafluoroheptyl methacrylate, vinyl triethyl Oxysilane is added into the reactor in parts by mass of 24.8, 12.5, 5.0, 5.0, and 2.5 and mixed evenly to obtain a mixed liquid a;

[0041] The catalyst azobisethylbutyronitrile (AIBN) of 0.2 parts by mass is completely dissolved in the solvent butyl acetate of 50.0 parts by mass to obtain mixed solution b;

[0042] Add the mixed solution b into the mixed solution a, and stir evenly to obtain the mixed solution c.

[0043] 2. Place the obtained mixed solution c in a water bath at 70° C. for 24 hours, and then cool it down to room temperature to obtain the amphiphilic acrylate polymer solution d modified by fluorosilicon copolymerization. P...

Embodiment 3

[0049] Anti-corrosion paint preparation method, the paint is carried out according to the following steps in 100 parts by mass:

[0050] 1. Preparation of amphiphilic acrylate polymer modified by fluorosilicone copolymerization: methyl methacrylate, n-butyl acrylate, β-hydroxypropyl acrylate, hexafluorobutyl methacrylate, vinyl trimethoxy Silane is added into the reactor in parts by mass of 24.8, 12.0, 5.0, 6.0, and 2.0 and mixed evenly to obtain a mixed liquid a;

[0051] The catalyst azobisethylbutyronitrile (AIBN) with a mass fraction of 0.2 is completely dissolved in the solvent butyl acetate with a mass fraction of 50.0 to obtain a mixed solution b;

[0052] Add the mixed solution b into the mixed solution a, and stir evenly to obtain the mixed solution c.

[0053] 2. Place the obtained mixed solution c in a water bath at 90° C. for 12 hours, and then cool it down to room temperature to obtain the amphiphilic acrylate polymer solution d modified by fluorosilicon copolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com