Self-emulsified cutting fluid and preparation method thereof

A cutting fluid, ammonium persulfate technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of polluted environment, poor cooling performance, poor lubricity and anti-rust effect, etc., and achieve excellent lubricating performance, good stability, The effect of high resistance to hard water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

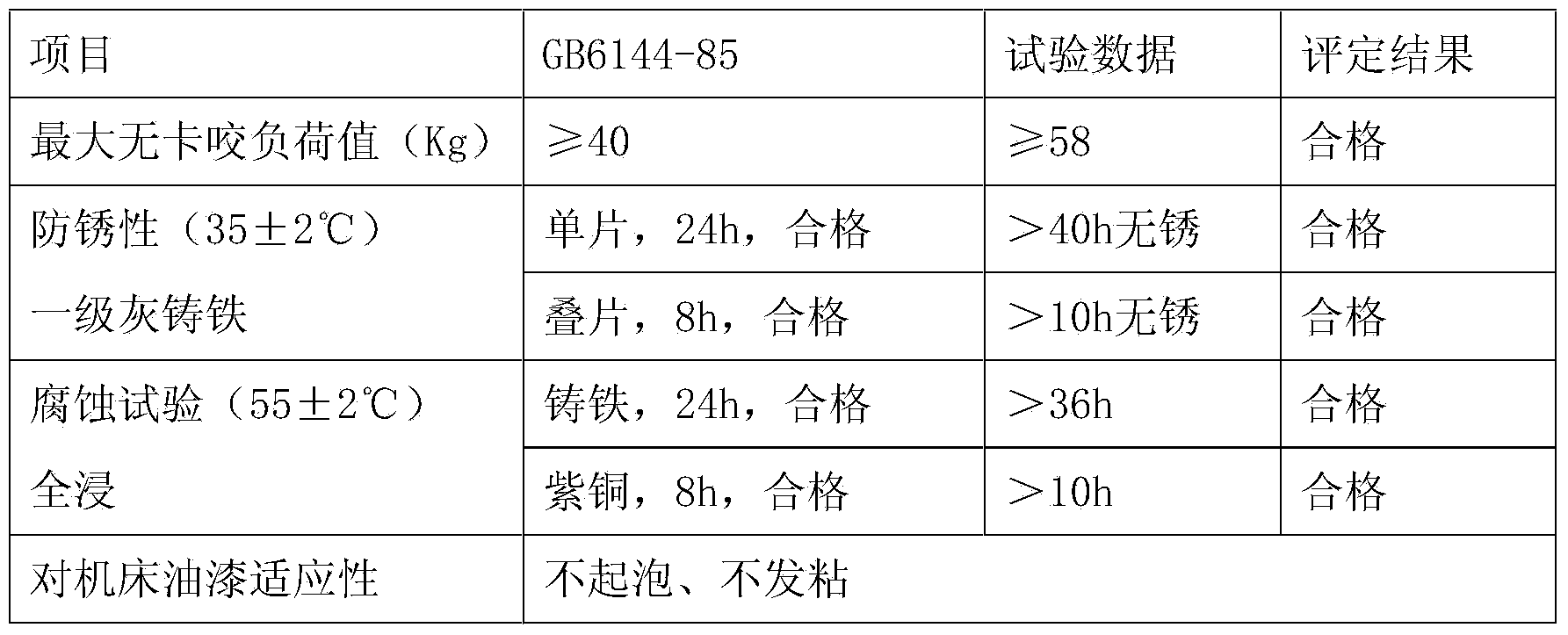

Image

Examples

Embodiment Construction

[0009] A self-emulsifying cutting fluid, made of the following raw materials in parts by weight (kg): 3.5 sodium molybdate, 2.5 disodium oxalate tetraacetate, 2.5 sodium silicate, 3.5 linolenic acid, 1.5 alkenyl succinic acid, Soybean oil 22, propylene glycol 22, trimethylolpropane 1.5, sodium dodecylbenzene sulfonate 3.5, ammonium persulfate 1.5, auxiliary agent 7, water 200; the auxiliary agent consists of the following raw materials in parts by weight (kg) Made: polyoxyethylene sorbitan monooleate 2, nano aluminum nitride 0.1, citric acid 1, sodium tripolyphosphate 3, ammonium persulfate 2, silane coupling agent KH-5602, sodium molybdate 2, Peach gum 3, water 20-24; the preparation method is to dissolve ammonium persulfate in water, then add other remaining materials, stir for 10-15 minutes, heat to 70-80°C, and stir for 1-2 hours to obtain the product.

[0010] The preparation method of the self-emulsifying cutting fluid comprises the following steps: mixing water, sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com