Preparation method, coating construction method and use of anti-corrosion coating and display frame

An anti-corrosion and coating technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor wear resistance, complicated preparation methods, and single display method of display racks, so as to improve wear resistance, hydrophobicity, and identity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

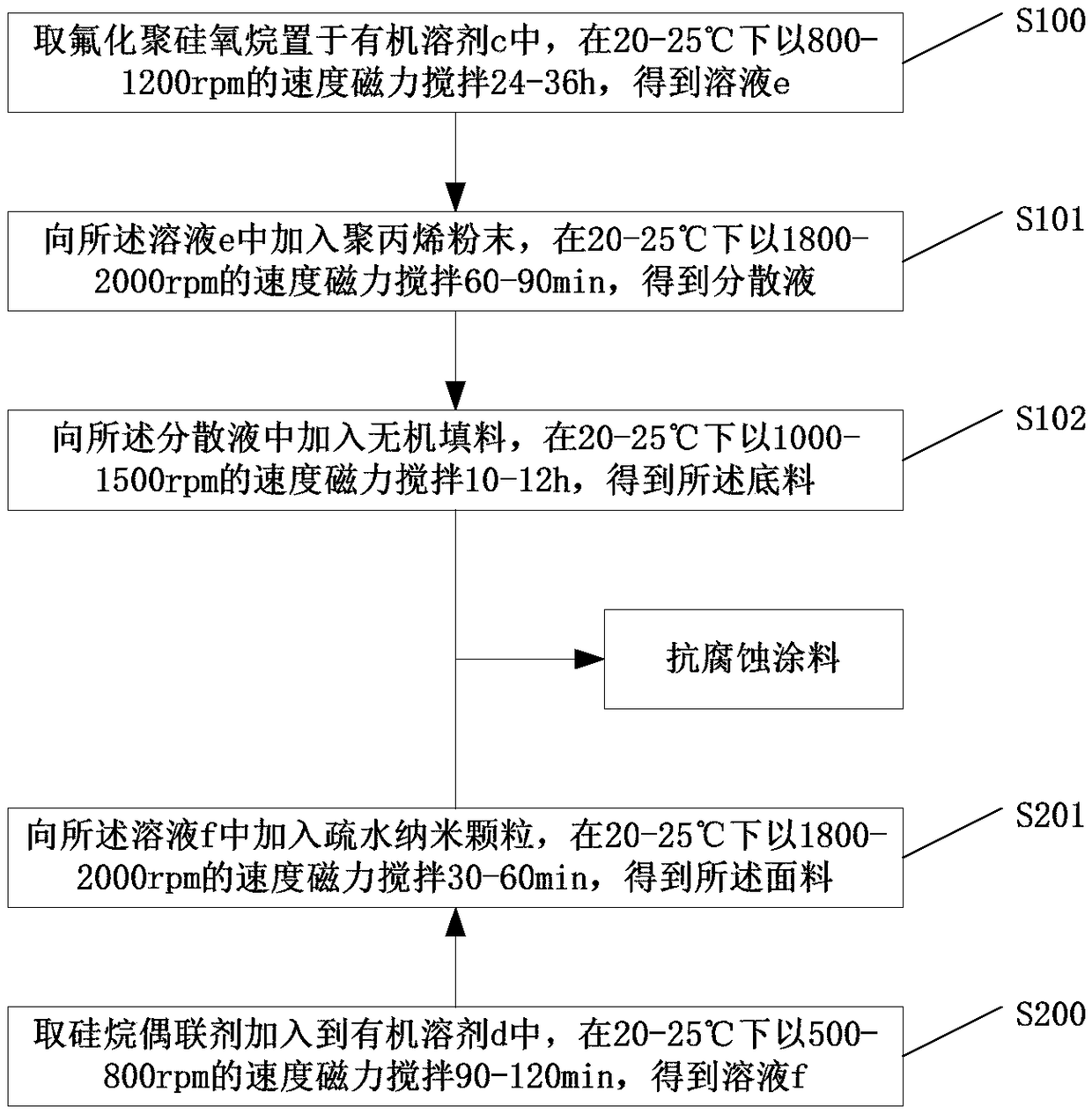

[0059] An embodiment of the present invention provides a method for preparing an anti-corrosion coating, the anti-corrosion coating includes a primer and a fabric,

[0060] The preparation method of described primer comprises:

[0061] Take the fluorinated polysiloxane in an organic solvent c, and magnetically stir at a speed of 800-1200rpm at 20-25°C for 24-36h to obtain a solution e, and the fluorinated polysiloxane is in the solution e The concentration is 1-10mg / mL.

[0062] The fluorinated polysiloxane contains the following structure:

[0063] Wherein, n is a positive integer, and the fluorinated polysiloxane containing the above structure has good thermal stability, and it is used in the anti-corrosion coating of the embodiment of the present invention, which can make it suffer from repeated mechanical friction and heat up, Remain stable without decomposition.

[0064] In the embodiment of the present invention, the fluorinated polysiloxane is polytrifluoropropylme...

Embodiment 1

[0089] A preparation method of an anti-corrosion coating, the anti-corrosion coating comprises a primer and a lining,

[0090] The preparation method of described primer comprises:

[0091] S100: 2.5 g of polytrifluoropropylmethylsiloxane was placed in 100 mL of tetrahydrofuran, and magnetically stirred at 800 rpm for 36 h at 25° C. to obtain a solution e.

[0092] S101: Add 0.25 g of polypropylene powder to the solution e, and magnetically stir at 25° C. at a speed of 1800 rpm for 90 min to obtain a dispersion liquid. The particle size of the polypropylene powder is 10 μm.

[0093] S102: Add 0.05 g of titanium dioxide to the dispersion, and magnetically stir at 1000 rpm for 12 hours at 25° C. to obtain the primer, and the particle size of the inorganic filler is 1 μm.

[0094] The preparation method of described lining comprises:

[0095] S200: Add 1.5 mL of 3-aminopropyltriethoxysilane into 100 mL of methanol, and magnetically stir at 500 rpm for 120 min at 25° C. to obtai...

Embodiment 2

[0098] A preparation method of an anti-corrosion coating, the anti-corrosion coating comprises a primer and a lining,

[0099] The preparation method of described primer comprises:

[0100] S100: 5 g of polymethylnonafluorohexylsiloxane was placed in 100 mL of ethyl acetate, and magnetically stirred at 25° C. at a speed of 1000 rpm for 36 h to obtain a solution e.

[0101] S101: Add 0.5 g of polypropylene powder to the solution e, and magnetically stir at 25° C. at a speed of 1800 rpm for 90 min to obtain a dispersion liquid. The particle size of the polypropylene powder is 10 μm.

[0102] S102: Add 0.1 g of silicon dioxide to the dispersion, and magnetically stir at 1200 rpm at 25° C. for 11 h to obtain the primer, and the particle size of the inorganic filler is 5 μm.

[0103] The preparation method of described lining comprises:

[0104] S200: Add 2 mL of 3-aminopropyltrimethoxysilane into 100 mL of ethanol, and magnetically stir at 500 rpm for 120 min at 25° C. to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com