Demulsifier for treating heavy oil and preparation method thereof

A technology for demulsifier and heavy oil, applied in the field of demulsifier for handling heavy oil and its preparation, can solve the problems of strong corrosion of equipment, poor demulsification and dehydration performance, unenvironmental protection, etc., achieves good water quality and is convenient for large-scale production , the effect of fast demulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

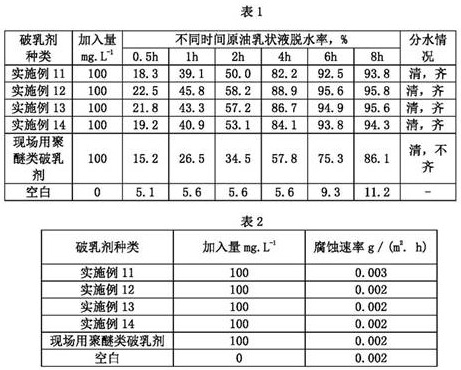

Examples

Embodiment 1

[0021] Embodiment 1: The demulsifier for processing heavy oil, raw materials include polyoxyethylene polyoxypropylene block copolymer 10% to 60%, keto acid 1% to 20%, acetylenic alcohol 0.01% to 5% by weight percentage, The balance is water.

[0022] The demulsifier for treating heavy oil of the present invention comprises polyoxyethylene polyoxypropylene block copolymer, keto acid, acetylenic alcohol and water as raw materials, can be quickly dispersed into oil-water emulsion, and has good demulsification performance on crude oil emulsion. The acidity of component keto acids is weaker than that of acetic acid, propionic acid, butyric acid, succinic acid, glutaric acid, adipic acid, fumaric acid, maleic acid and citric acid, and its corresponding corrosiveness is also low. On the one hand, alcohol has the function of solvent, on the other hand, it has anti-rust and anti-corrosion effect, which solves the corrosion problem of existing demulsifier products very well. Moreover, ...

Embodiment 2

[0023] Embodiment 2: The demulsifier for the treatment of heavy oil, raw materials include polyoxyethylene polyoxypropylene block copolymer 10% or 60%, keto acid 1% or 20%, acetylenic alcohol 0.01% or 5% by weight percentage, The balance is water.

Embodiment 3

[0024] Example 3: As an optimization of the above example, it is obtained according to the following method: heat the required amount of polyoxyethylene polyoxypropylene block copolymer to 30°C to 60°C in the reactor, and add the required amount to the reactor The required amount of keto acid, acetylenic alcohol and the rest of water are used to obtain a mixed material; the mixed material is kept warm at 30°C to 60°C and stirred until the material is completely dissolved to form a uniform liquid, and a demulsifier for treating heavy oil is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com