Preparation method of MIL-100 (Fe) composite material capable of circularly and quickly demulsifying

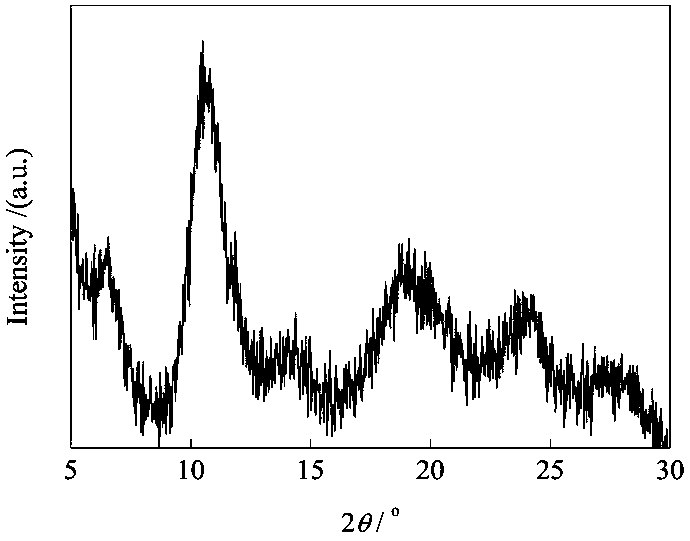

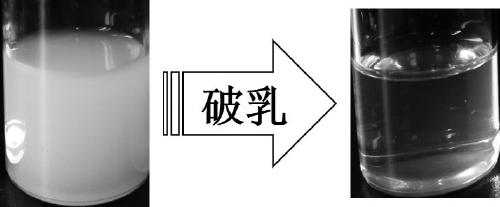

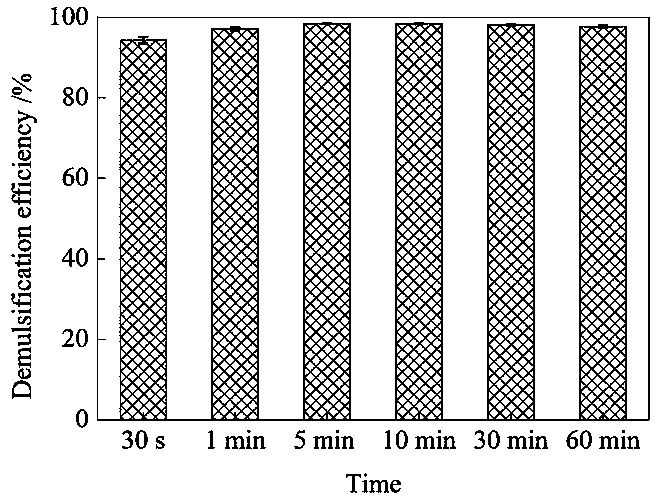

A composite material and demulsification technology, which is applied in separation methods, chemical instruments and methods, and immiscible liquid separation, etc., can solve the problems of blank and lack of MIL-100 demulsification research, and achieve ultra-fast demulsification speed and stability Effect of cyclic demulsification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1. Dissolve 0.11g of 1-allyl-3-methylimidazole chloride (AmimCl) in 10ml of water to prepare AmimCl aqueous solution, and dissolve 0.315g of trimesic acid (BTC) in 10ml of methanol to prepare methanol containing BTC solution;

[0024] Step 2. Get 0.54g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) be dissolved in the 10mlAmimCl aqueous solution that above-mentioned step (1) prepares, obtain solution A;

[0025] Step 3. Add 10ml of the BTC-containing methanol solution in step 1 dropwise to the solution A under stirring at room temperature, and the dropping speed is 1-2 drops / second. Stirring was continued for 12 hours after the dropwise addition was complete. The product is centrifuged, washed, dried, and ground to obtain a beige powder sample, which is the MIL-100(Fe) composite material anchored by the positive charge carrier of the ionic liquid AmimCl (named Amim@MIL-100(Fe) -1:3).

Embodiment 2

[0027] Step 1. Dissolve 0.228g 1-allyl-3-methyl imidazole chloride (AmimCl) in 10ml water to prepare AmimCl aqueous solution, and dissolve 0.315g trimesic acid (BTC) in 10ml methanol to prepare methanol containing BTC solution;

[0028] Step 2. Get 0.54g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) be dissolved in the 10mlAmimCl aqueous solution that above-mentioned step (1) prepares, obtain solution B;

[0029] Step 3. Add 10ml of the BTC-containing methanol solution in step 1 dropwise to the solution B under stirring at room temperature, and the dropping speed is 1-2 drops / second. Stirring was continued for 12 hours after the dropwise addition was complete. The product is centrifuged, washed, dried, and ground to obtain a beige powder sample, which is the MIL-100(Fe) composite material anchored by the positive charge carrier of the ionic liquid AmimCl (named Amim@MIL-100(Fe) -2:3).

Embodiment 3

[0031] Step 1. Dissolve 0.317g 1-allyl-3-methylimidazole chloride (AmimCl) in 10ml water to prepare AmimCl aqueous solution, and dissolve 0.315g trimesic acid (BTC) in 10ml methanol to prepare methanol containing BTC solution;

[0032] Step 2. Get 0.54g ferric chloride hexahydrate (FeCl3 ·6H 2 O) be dissolved in the 10mlAmimCl aqueous solution that above-mentioned step (1) prepares, obtain solution C;

[0033] Step 3. Add 10 ml of BTC-containing methanol solution in step 1 dropwise to solution C under stirring at room temperature, and the dropping speed is 1-2 drops / second. Stirring was continued for 12 hours after the dropwise addition was complete. The product is centrifuged, washed, dried, and ground to obtain a beige powder sample, which is the MIL-100(Fe) composite material anchored by the ionic liquid AmimCl as a positive charge carrier (named Amim@MIL-100(Fe) -3:3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com