De-emulsifiers for oil and gas gathering and transferring and production device thereof

A technology for oil and gas gathering and production equipment, which is applied in chemical dehydration/emulsification, transportation, packaging, dissolution, etc., and can solve the problems of inability to meet various needs of crude oil production, secondary pollution, poor friendliness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

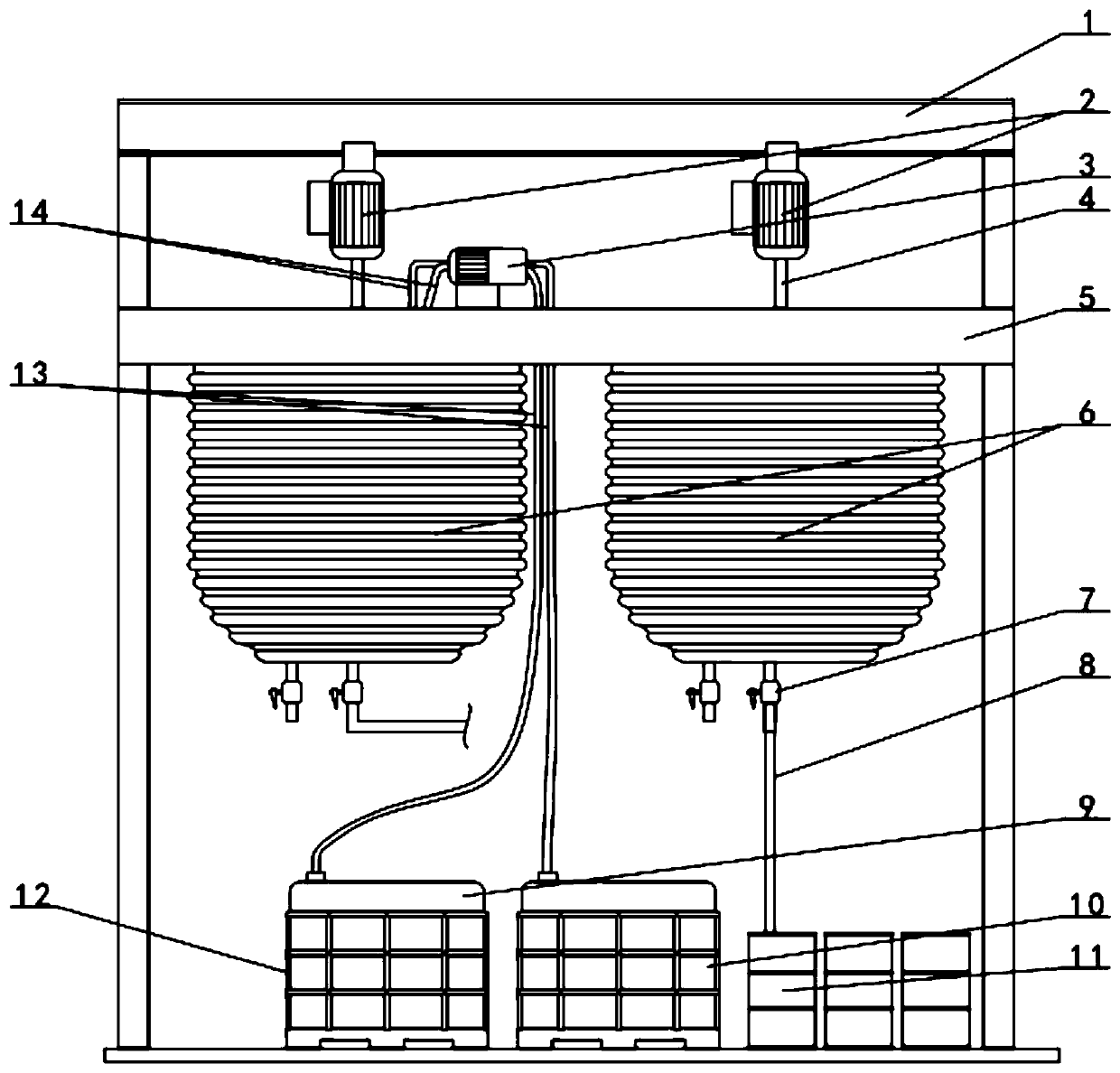

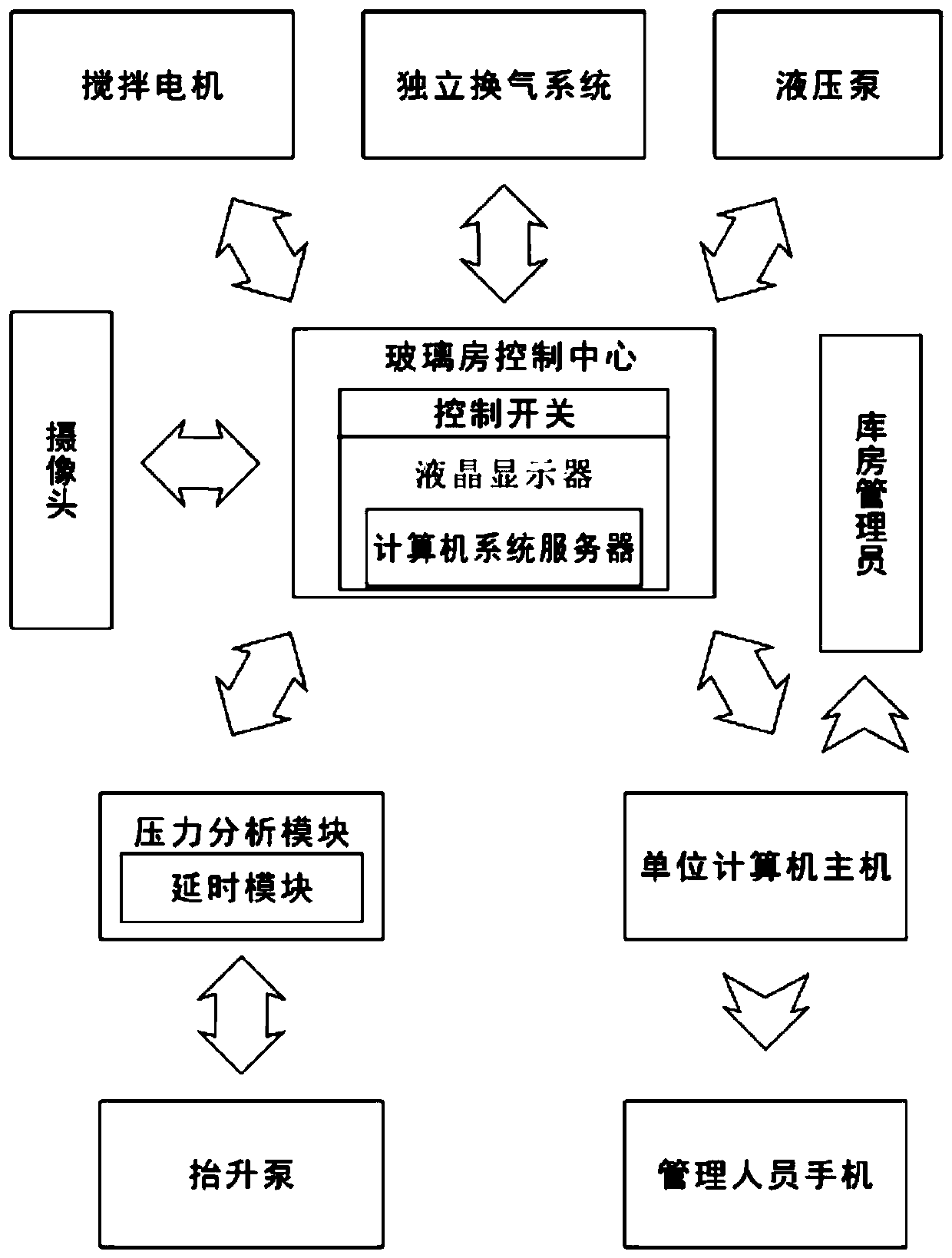

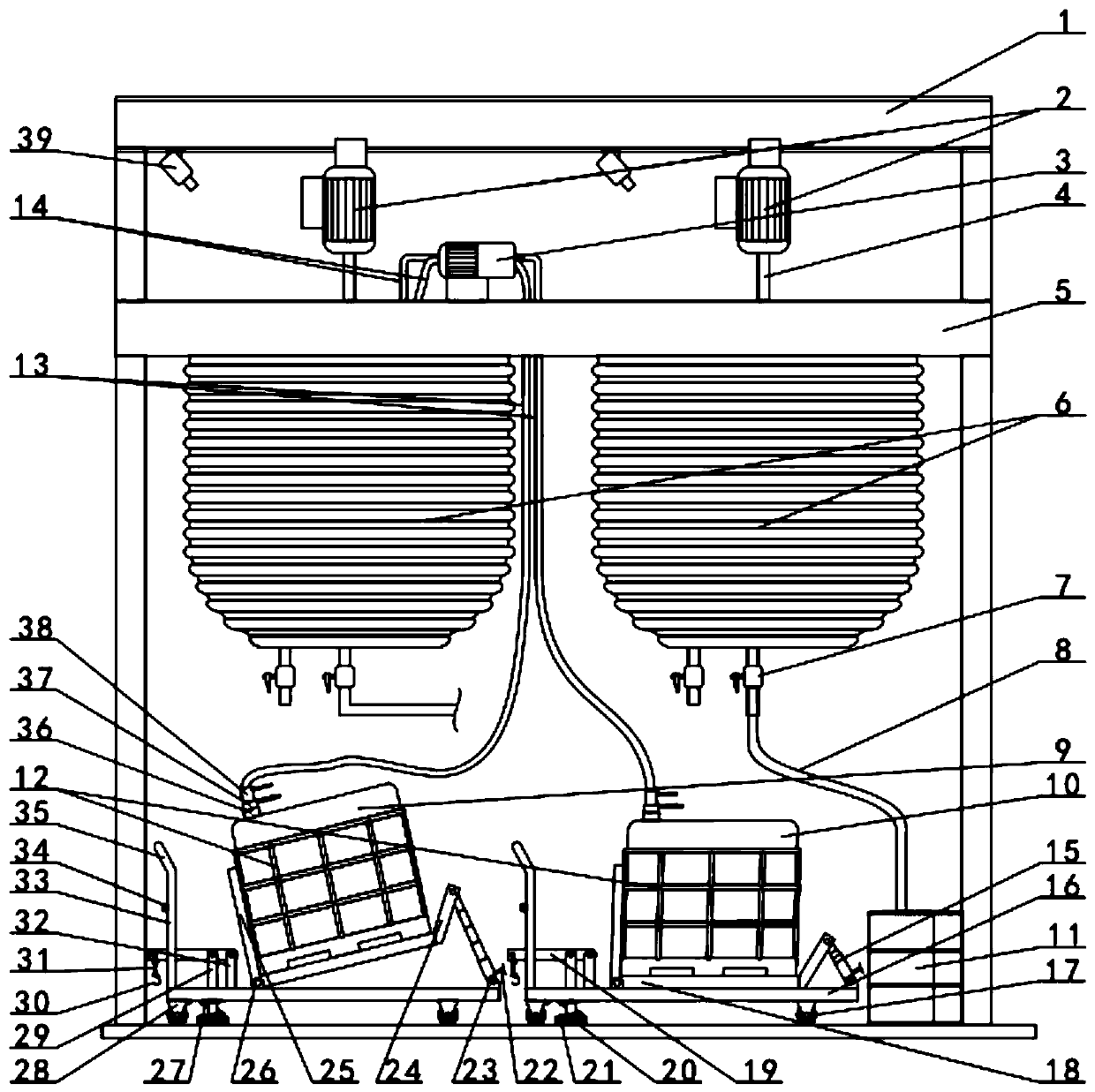

Method used

Image

Examples

Embodiment 1

[0042] A type I demulsifier for oil and gas gathering and transportation comprises the following raw materials in parts by weight: 45 parts of propylene oxide, 45 parts of ethylene oxide, 10 parts of sodium chloride, 15 parts of sodium benzoate, and an appropriate amount of water.

Embodiment 2

[0044] A demulsifier for oil and gas gathering and transportation, type II contains the following raw materials in parts by weight: 25 parts of phenol, 43 parts of diethylenetriamine, 25 parts of formaldehyde, 4 parts of potassium hydroxide, 35 parts of propylene oxide, ethylene oxide 35 parts, 12 parts of sodium benzoate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com