Preparation method of block polyether type ageing oil demulsifier

A technology of block polyether and oil demulsifier, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of complex aging oil composition, reduced electric dehydration efficiency, electric field breakdown, etc. Demulsification effect, the effect of fast demulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

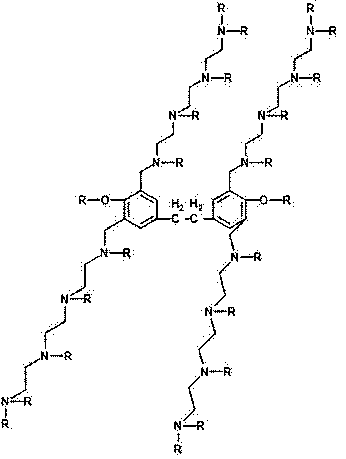

[0018] The invention relates to a preparation method of a block polyether type aging oil demulsifier, the general structural formula of the demulsifier is as follows:

[0019]

[0020] in:

[0021] Described preparation method comprises the steps:

[0022] In the first step, put quantitative phenol and ethylene glycol into the first four-part bottle, and the mass ratio of phenol to ethylene glycol added is between 9:1 and 9.5:1; add to the four-part bottle Hydrogen chloride and methanol solution as solvent, the consumption of hydrogen chloride is 3% of the total mass of phenol and ethylene glycol in the quarter bottle, the concentration of methanol solution is 30%, and the consumption is 50% of the total mass of phenol and ethylene glycol in the quarter bottle ;Heat the material in the above-mentioned four-part bottle to 75°C-85°C, and the reaction time is 2.5h. After the reaction is complete, distill at 45°C for 0.5h to obtain the intermediate product A;

[0023] In th...

Embodiment approach

[0027] In the first step, the mass ratio of phenol to ethylene glycol is 9.1:1;

[0028] In the first step, the reaction temperature for generating intermediate product A is 80°C;

[0029] In the second step, the molar ratio of intermediate product A, formaldehyde and triethylenetetramine is 1:4:4, that is, the mass ratio is 1.78:1:4.87;

[0030] In the second step, the dissolution temperature of intermediate product A and triethylenetetramine is 50°C, the reaction temperature of intermediate product A, triethylenetetramine mixed solution and formaldehyde solution is 190°C, and the reaction time is 1h;

[0031] In the second step, the amount of xylene is 50% of the total mass of the material, the reflux dehydration temperature is 100°C to 110°C, and the reflux dehydration time is 2h;

[0032] In the third step and the fourth step, the reaction temperature in the kettle is 140°C, and the pressure gauge reading of the reactor is between 0.2±0.01Mpa during the reaction;

[0033...

Embodiment 1

[0042] Take 45.5g of phenol and 5g of ethylene glycol into the quarter bottle, take 1.515g of hydrogen chloride dropwise into the quarter bottle, then add 26g of methanol solution, heat it with a water bath while stirring, the temperature rises to 80°C, and wait for 2.5 hours to react Fully, stop the stirring, heat the remaining substance to 45°C and distill for 0.5h to obtain the dry liquid of the substance, which is the intermediate product A.

[0043] Take 15g of intermediate product A and 41.1g of triethylenetetramine and put them into a four-neck bottle, heat up the water bath to 50°C to dissolve completely, keep it warm for 15min, then slowly add 8.43g of formaldehyde dropwise, keep it warm for 30min after the dropwise addition, add 32.27g of diethylenetetramine For toluene, heat up to 105°C for reflux dehydration, and then gradually raise the temperature to 190°C after 2 hours. At this time, the transparency of the reactants and xylene gradually increases, and the xylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com