Method for improving demulsification performance of cell wall combined biological de-emulsifier

A biological demulsifier and combined technology, applied in the field of environmental microorganisms, can solve problems that do not involve the performance optimization of downstream biological demulsifiers, and achieve the effects of easy large-scale industrial application, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

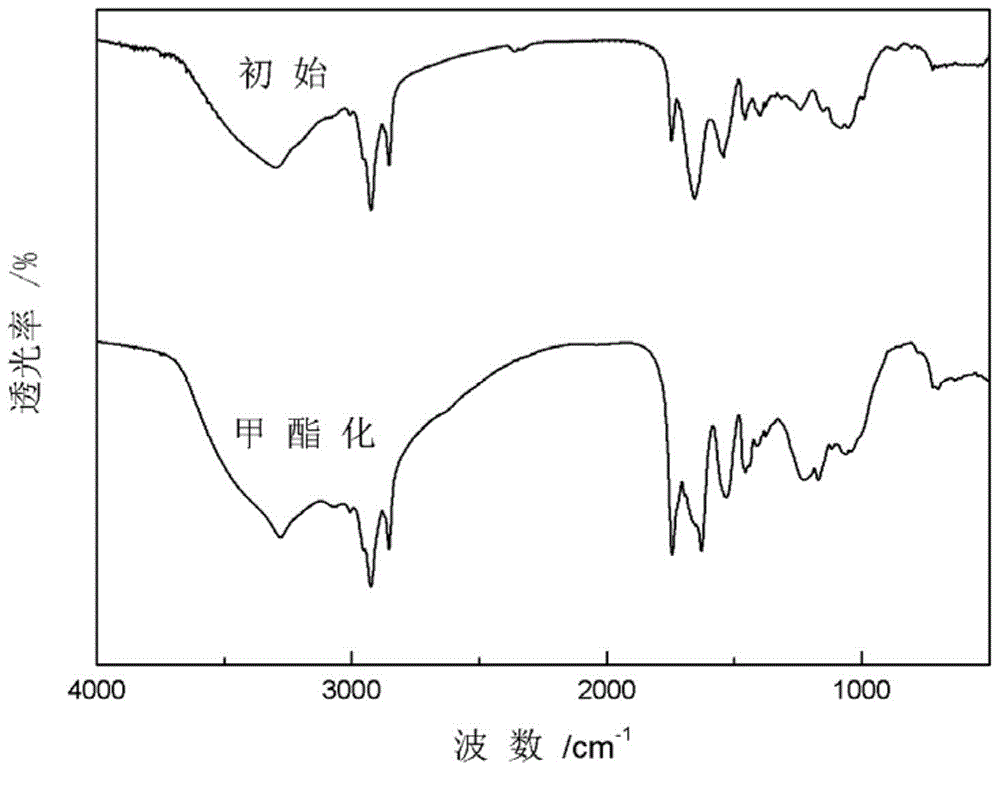

[0036] 1. Add 0.5 g of cell wall-bound biodemulsifier dry powder produced by Alcaligenes sp.S-XJ-1 cultured with rapeseed oil as a carbon source into a 50 mL CH 3 OH and 0.42mL HCl in a Erlenmeyer flask.

[0037] 2. Place the Erlenmeyer flask containing the cell wall-bound biodemulsifier and reagents on a magnetic stirrer, add a magnetic stirrer, adjust the temperature to 25°C, set the speed to 500rpm, and stir for 24 hours.

[0038] 3. The obtained mixture was subjected to rotary evaporation, and the temperature of the rotary evaporation was set to 40°C. The time is 15-20min.

[0039] 4. Place the obtained biodemulsifier in an oven at a temperature of 80° C. to dry for 24 hours, and collect the obtained biodemulsifier.

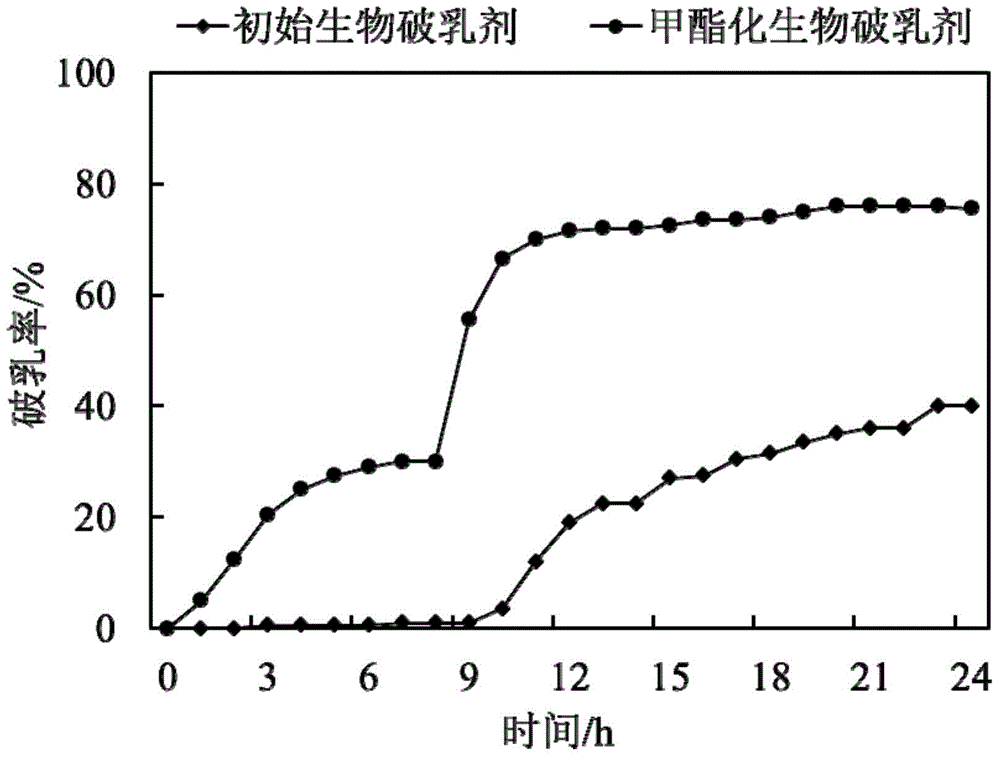

[0040]5. Weigh a certain amount of biological demulsifier, dissolve it in water to make a 10g / L solution, take 2mL and add it to the demulsification tube, then add 18mL model emulsion, shake vigorously for 120 times, put it in a 35℃ water bath for 24 hours,...

Embodiment 2

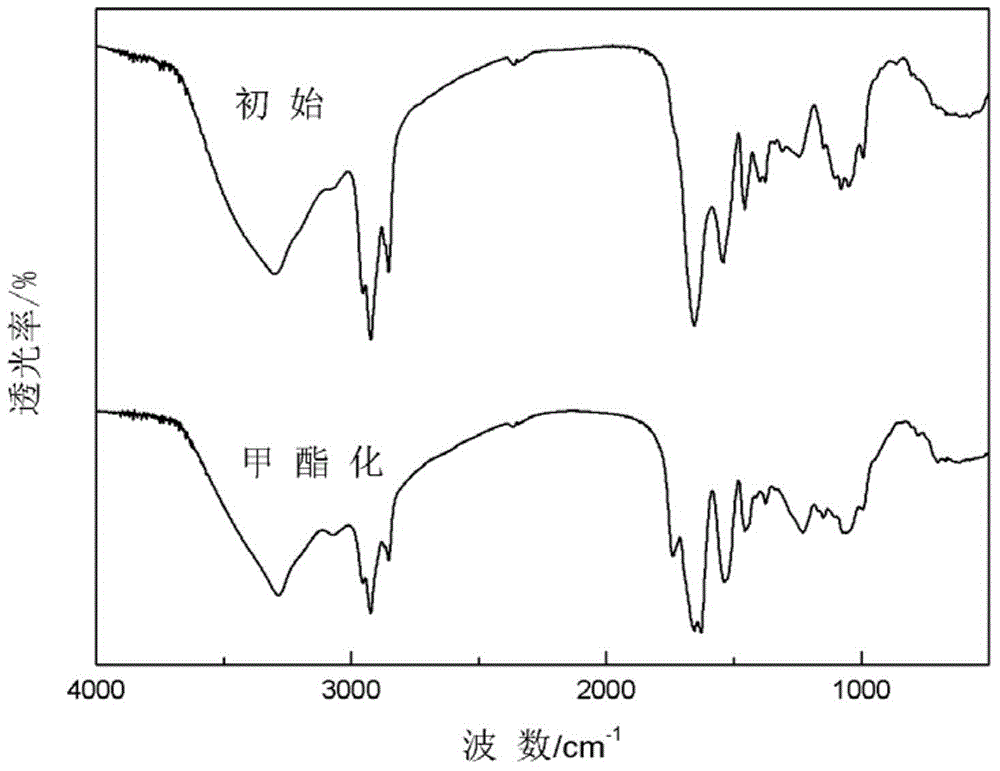

[0043] 1. Add 0.5 g of cell wall-bound biodemulsifier produced by Alcaligenes sp.S-XJ-1 cultured with paraffin as a carbon source into 50 mL CH 3 OH and 0.42mL HCl in a Erlenmeyer flask.

[0044] 2. Place the Erlenmeyer flask containing the cell wall-bound biodemulsifier and reagents on a magnetic stirrer, add a magnetic stirrer, adjust the temperature to 25°C, set the speed to 500rpm, and stir for 24 hours.

[0045] 3. The obtained mixture was subjected to rotary evaporation, and the temperature of the rotary evaporation was set to 40°C. The time is 15-20min.

[0046] 4. Place the obtained biodemulsifier in an oven at a temperature of 80° C. to dry for 24 hours, and collect the obtained biodemulsifier.

[0047] 5. Weigh a certain amount of biological demulsifier, dissolve it in water to make a 10g / L solution, take 2mL and add it to the demulsification tube, then add 18mL model emulsion, shake vigorously for 120 times, put it in a 35℃ water bath for 24 hours, and observe the...

Embodiment 3

[0050] A method for improving the demulsification performance of a cell wall-bound biological demulsifier, the method comprising the following steps: freeze-drying the dry powder of the cell wall-bound biological demulsifier (generated by Alcaligenes sp.S-XJ-1) , to obtain dry powder of biological demulsifier, then mix and stir the dry powder of biological demulsifier with a certain proportion of methanol and hydrochloric acid mixed solution to carry out methyl esterification reaction, and finally, after rotary evaporation and drying, the cell wall-bound biological demulsifier with improved demulsification performance is obtained. Demulsifier.

[0051] The specific process of the methyl esterification reaction is as follows: the dry powder of the biological demulsifier is added to the mixed solution of methanol and hydrochloric acid with a volume ratio of 50:1, and the solid-liquid ratio of the dry powder of the biological demulsifier to the mixed solution is controlled at 0.00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com