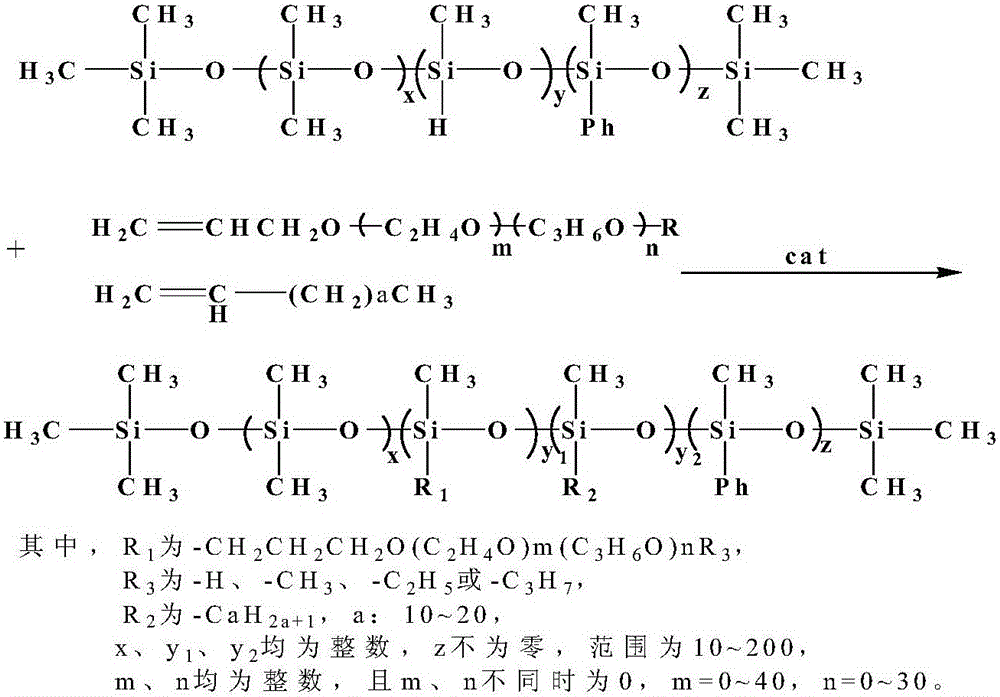

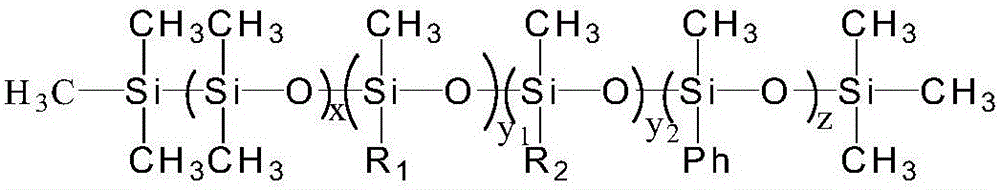

Oil-soluble demulsifier and preparation method thereof

A demulsifier, oil-soluble technology, applied in the field of oil-soluble demulsifier and its preparation, can solve the problems of difficult control of esterification reaction conditions, unsuitable for large-scale production, incomplete reaction, etc., to achieve good emulsification stability, excellent Application effect, effect of improving demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

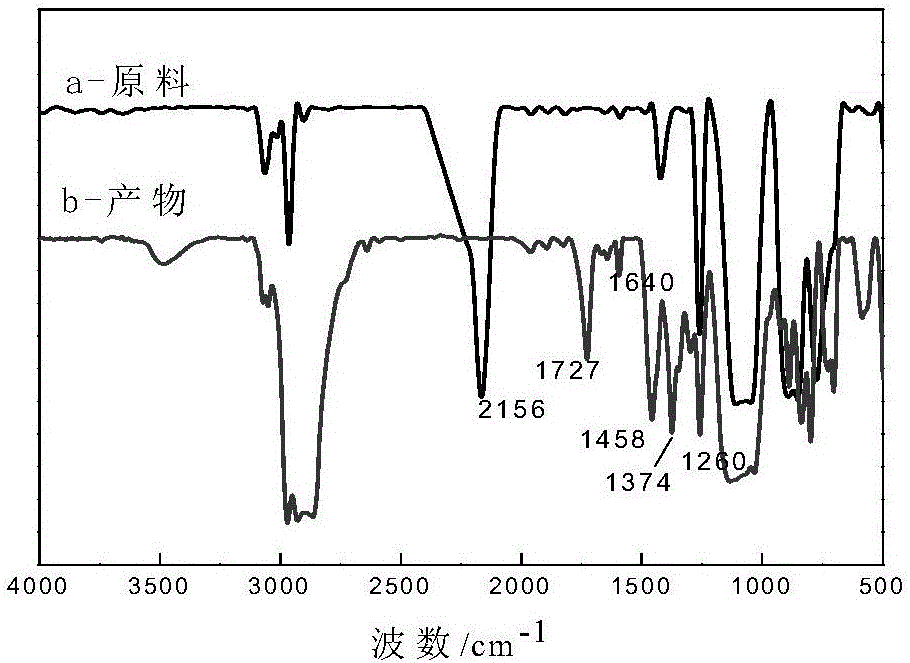

Method used

Image

Examples

Embodiment 1

[0043] Add 1.25g of phenyl hydrogen-containing silicone oil and 1.19g of isopropanol into the reaction kettle, raise the temperature to 70°C under stirring, and add 1.19×10 -4 g catalyst, then warmed up to 80°C, and then added dropwise a mixture of 0.8416g 1-dodecene and 1.875g polyether for 10 minutes. Low boilers and unreacted raw materials, resulting in oil-soluble demulsifiers.

Embodiment 2

[0045] Add 1.25g of phenyl hydrogen-containing silicone oil and 1.23g of isopropanol into the reaction kettle, raise the temperature to 70°C under stirring, and add 1.23×10 -4 g catalyst, then heated up to 90°C, and then added dropwise a mixture of 0.8837g 1-dodecene and 1.969g polyether for 20 minutes. Low boilers and unreacted raw materials, resulting in oil-soluble demulsifiers.

Embodiment 3

[0047] Add 1.25g of phenyl hydrogen-containing silicone oil and 1.27g of isopropanol into the reaction kettle, raise the temperature to 70°C under stirring, and add 1.27×10 -4 g catalyst, then warmed up to 100°C, and then added dropwise a mixture of 0.9258g 1-dodecene and 2.063g polyether for 30 minutes. Low boilers and unreacted raw materials, resulting in oil-soluble demulsifiers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com