Amphoteric organic polymer compound and preparation method thereof

An organic polymer and compound technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of increased synthesis cost, high equipment requirements, single function, etc., and achieves the effect of fast dehydration speed, weakening strength, and high dehydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

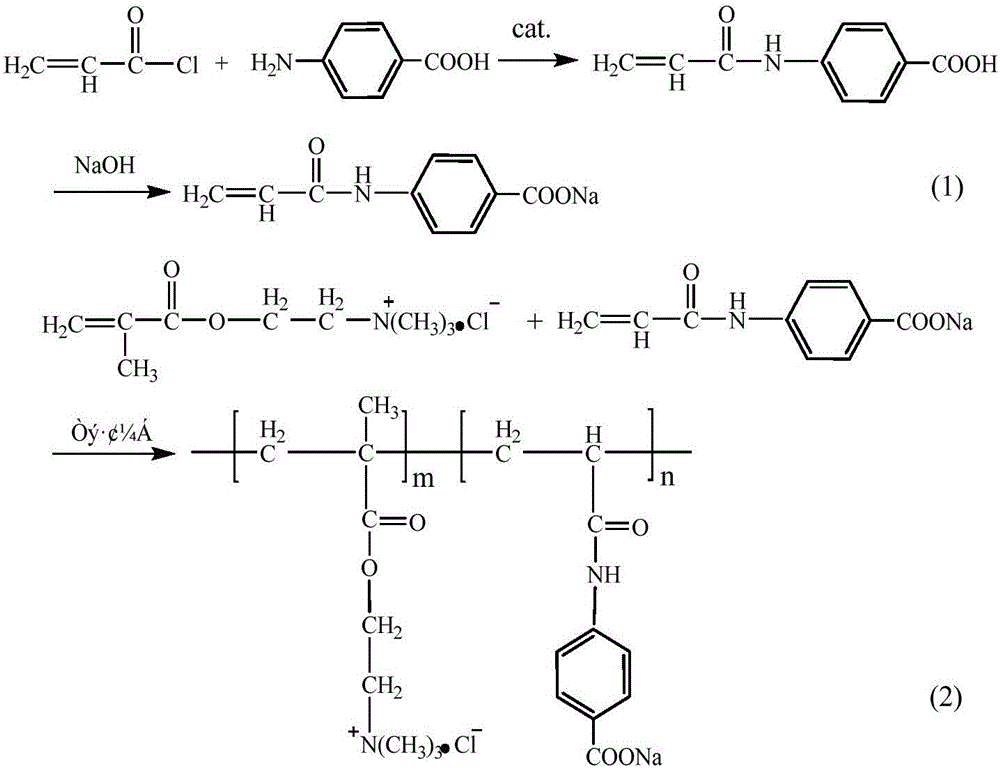

[0028] see figure 1 , the preparation method of a kind of organic macromolecular compound of the present invention comprises the aminolysis reaction of acyl chloride and polymerization reaction, and concrete steps are as follows:

[0029] (1) Add a certain amount of p-aminobenzoic acid and ethyl acetate as a solvent into a three-neck flask equipped with a stirrer, a constant pressure dropping funnel, and a condenser, and slowly add it dropwise with a constant pressure funnel at 0°C to 40°C Appropriate amount of acryloyl chloride, and fully stirred, after reacting for 1h~3h, remove the solvent ethyl acetate by suction filtration to obtain p-acrylamide benzoic acid, and then use a certain concentration of sodium hydroxide solution (mass fraction is 30%~60%) And until the p-acrylamide benzoic acid is completely dissolved, the water is distilled off under reduced pressure to obtain sodium p-acrylamide benzoate; wherein, the molar ratio of p-aminobenzoic acid to acryloyl chloride i...

Embodiment 1

[0033] A kind of preparation of organic polymer compound, comprises the following steps:

[0034] (1) Add 13.7g of p-aminobenzoic acid and 25mL of ethyl acetate into a 100mL three-necked flask equipped with a stirrer, a constant pressure dropping funnel and a condenser, and slowly add 13.5g of p-aminobenzoic acid and 25mL of ethyl acetate dropwise at 0°C with a constant pressure funnel. Acryloyl chloride, and fully stirred, after reacting for 2 hours, remove the solvent ethyl acetate by suction filtration, and wash twice with ethyl acetate to remove unreacted p-aminobenzoic acid to obtain white powder of p-acrylamide benzoic acid, and dry it; then use A sodium hydroxide solution with a mass fraction of 30% was slowly added dropwise until the p-acrylamide benzoic acid was completely dissolved, the water was distilled off under reduced pressure, dried in vacuum, and pulverized to obtain a white powder of sodium p-acrylamide benzoate;

[0035] (2) Add 19.9g of sodium p-acrylamide...

Embodiment 2

[0037] A kind of preparation of organic polymer compound, comprises the following steps:

[0038] (1) Add 13.7g of p-aminobenzoic acid and 30mL of ethyl acetate into a three-necked flask equipped with a stirrer, a constant pressure dropping funnel and a condenser, and slowly add 9g of acryloyl chloride dropwise with a constant pressure funnel at 10°C, And fully stirred, after reacting for 1 hour, the solvent ethyl acetate was removed by suction filtration, and washed twice with ethyl acetate to remove unreacted p-aminobenzoic acid to obtain a white powder of p-acrylamide benzoic acid, which was then dried; then with a mass fraction of 35 % sodium hydroxide solution was slowly added dropwise until the p-acrylamide benzoic acid was completely dissolved, the water was distilled off under reduced pressure, vacuum dried, and pulverized to obtain a white powder of sodium p-acrylamide benzoate;

[0039](2) Add 19.9g of sodium p-acrylamide benzoate into the reaction kettle, and add 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com