Biodegradable polymer heavy oil demulsifier and preparation method thereof

A technology of biodegradation and polymer, applied in chemical dehydration/demulsification, treatment of hydrocarbon oil, petroleum industry, etc., can solve the problems of ecological system and human society, high oil content in water, damage to natural environment, etc., to achieve Alleviate the pressure on the ecological environment, high dehydration rate, and the effect of being friendly to the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

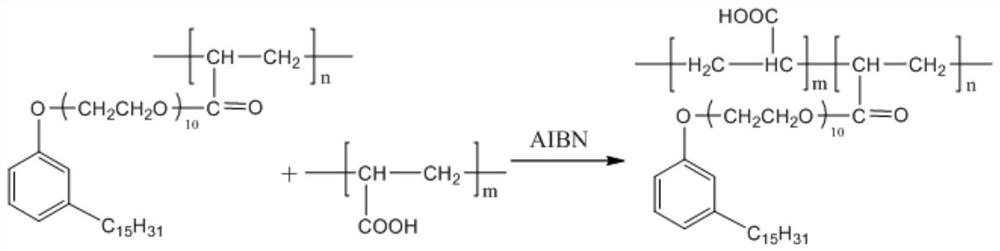

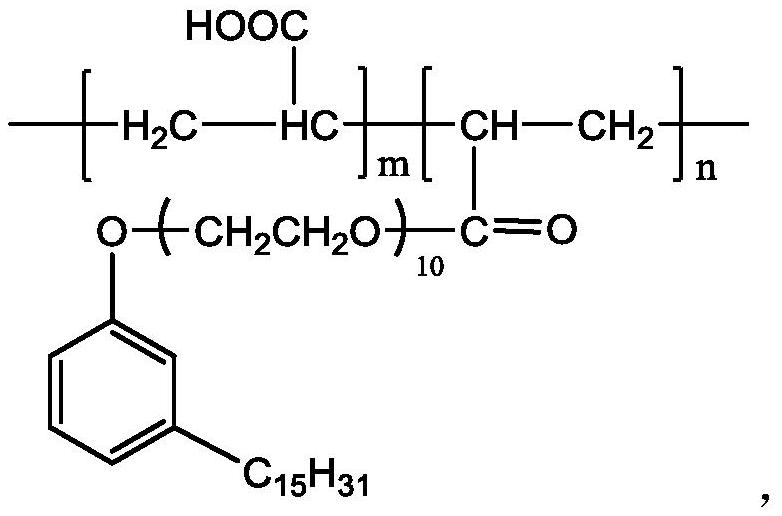

[0058] A preparation method of a green biodegradable polymer heavy oil demulsifier, comprising addition polymerization of cardanol polyoxyethylene acrylate and acrylic acid to obtain a green biodegradable polymer heavy oil demulsifier, the specific process is :

[0059] Step 1, in two clean beakers, weigh 15g cardanol polyoxyethylene acrylate (BGFAA) and 6g acrylic acid (AA) respectively;

[0060] Step 2, weigh 0.315g of initiator azobisisobutyronitrile (AIBN) in a small beaker, and dissolve it with the acrylic acid weighed in step 1 to obtain solution a;

[0061] Step 3, adding cardanol polyoxyethylene acrylate (BGFAA) weighed in step 1 and 12.6 g of toluene solvent into a three-necked flask together to obtain solution b;

[0062] Step 4, after stirring the solution b in step 3 and raising the temperature to 50°C, use a constant pressure dropping funnel to add solution a dropwise, and after 30min all the addition is completed, continue to stir and heat up to 120°C;

[0063]...

Embodiment 2

[0068] A preparation method of a green biodegradable polymer heavy oil demulsifier, comprising addition polymerization of cardanol polyoxyethylene acrylate and acrylic acid to obtain a green biodegradable polymer heavy oil demulsifier, the specific process is :

[0069] Step 1, in two clean beakers, weigh 15g cardanol polyoxyethylene acrylate (BGFAA) and 3g acrylic acid (AA) respectively;

[0070] Step 2, weigh 0.306g of the initiator azobisisobutyronitrile (AIBN) in a small beaker, and dissolve it with the acrylic acid weighed in step 1 to obtain solution a;

[0071] Step 3, adding cardanol polyoxyethylene acrylate (BGFAA) weighed in step 1 and 10.8 g of toluene solvent into a three-necked flask together to obtain solution b;

[0072] Step 4: Stir the solution b in step 3 and raise the temperature to 55°C, then add the solution a dropwise with a constant pressure dropping funnel, and after 30 minutes, continue to stir and raise the temperature to 130°C;

[0073] Step 5, tim...

Embodiment 3

[0078] A preparation method of a green biodegradable polymer heavy oil demulsifier, comprising addition polymerization of cardanol polyoxyethylene acrylate and acrylic acid to obtain a green biodegradable polymer heavy oil demulsifier, the specific process is :

[0079] Step 1, in two clean beakers, weigh 12g cardanol polyoxyethylene acrylate (BGFAA) and 4g acrylic acid (AA) respectively;

[0080] Step 2, weigh 0.256g of initiator azobisisobutyronitrile (AIBN) in a small beaker, and dissolve it with the acrylic acid weighed in step 1 to obtain solution a;

[0081] Step 3, adding cardanol polyoxyethylene acrylate (BGFAA) weighed in step 1 and 11.2 g of toluene solvent into a three-necked flask together to obtain solution b;

[0082] Step 4, after stirring the solution b in step 3 and raising the temperature to 60°C, use a constant pressure dropping funnel to add solution a dropwise, and after 25 minutes, continue to stir and raise the temperature to 120°C;

[0083] Step 5, ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com