A method for efficient biodegradation of crystalline plastics

A biodegradable and crystalline technology, applied in the field of bioengineering technology and environmental engineering, can solve the problems of low biodegradation efficiency of crystalline plastics, and achieve the effect of increasing the probability, efficient biodegradation and reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for highly efficient biodegradation of crystalline plastics, comprising the steps of:

[0053] Described crystalline plastic is polyethylene terephthalate (PET), polybutylene terephthalate (PBT), and its processing steps are as follows:

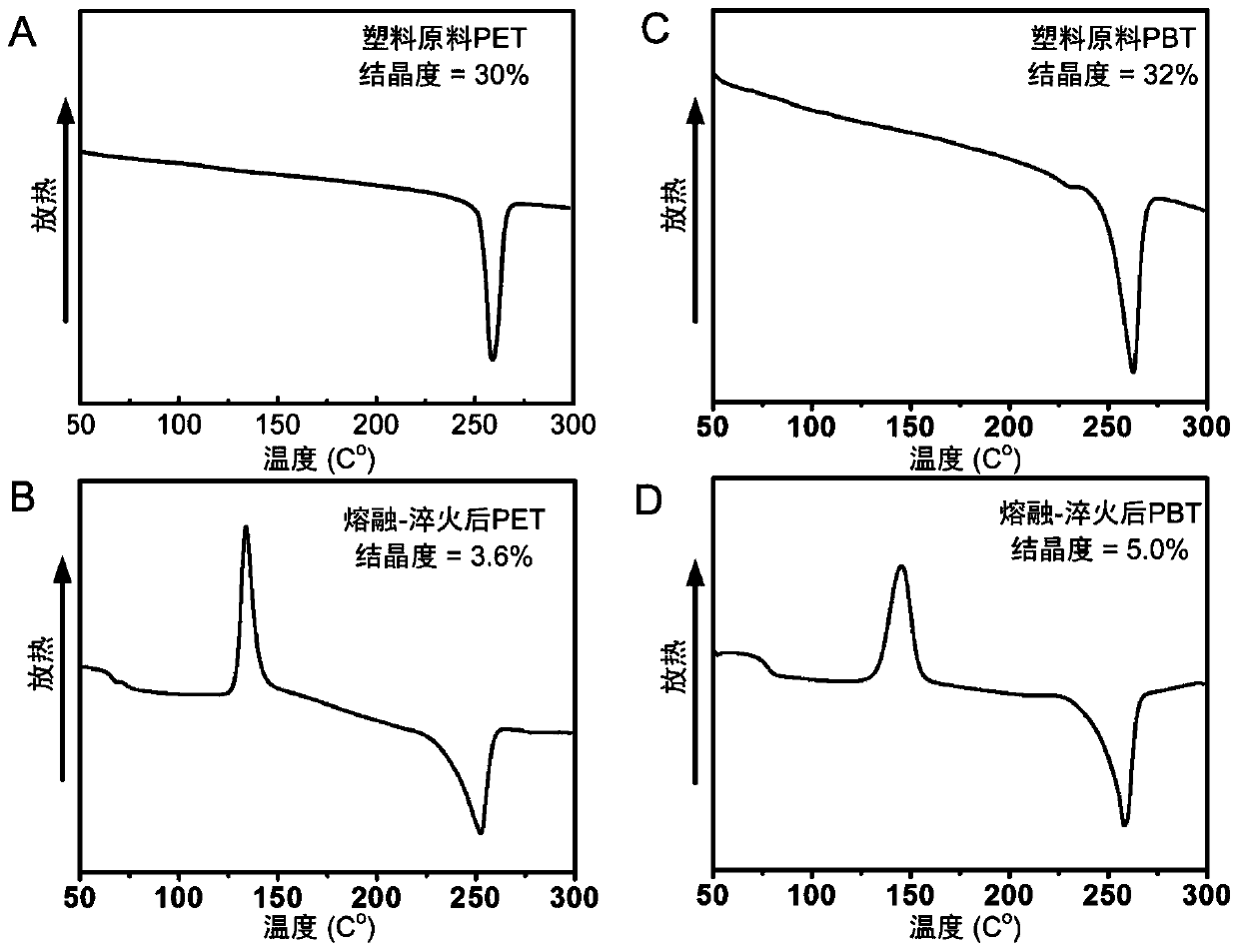

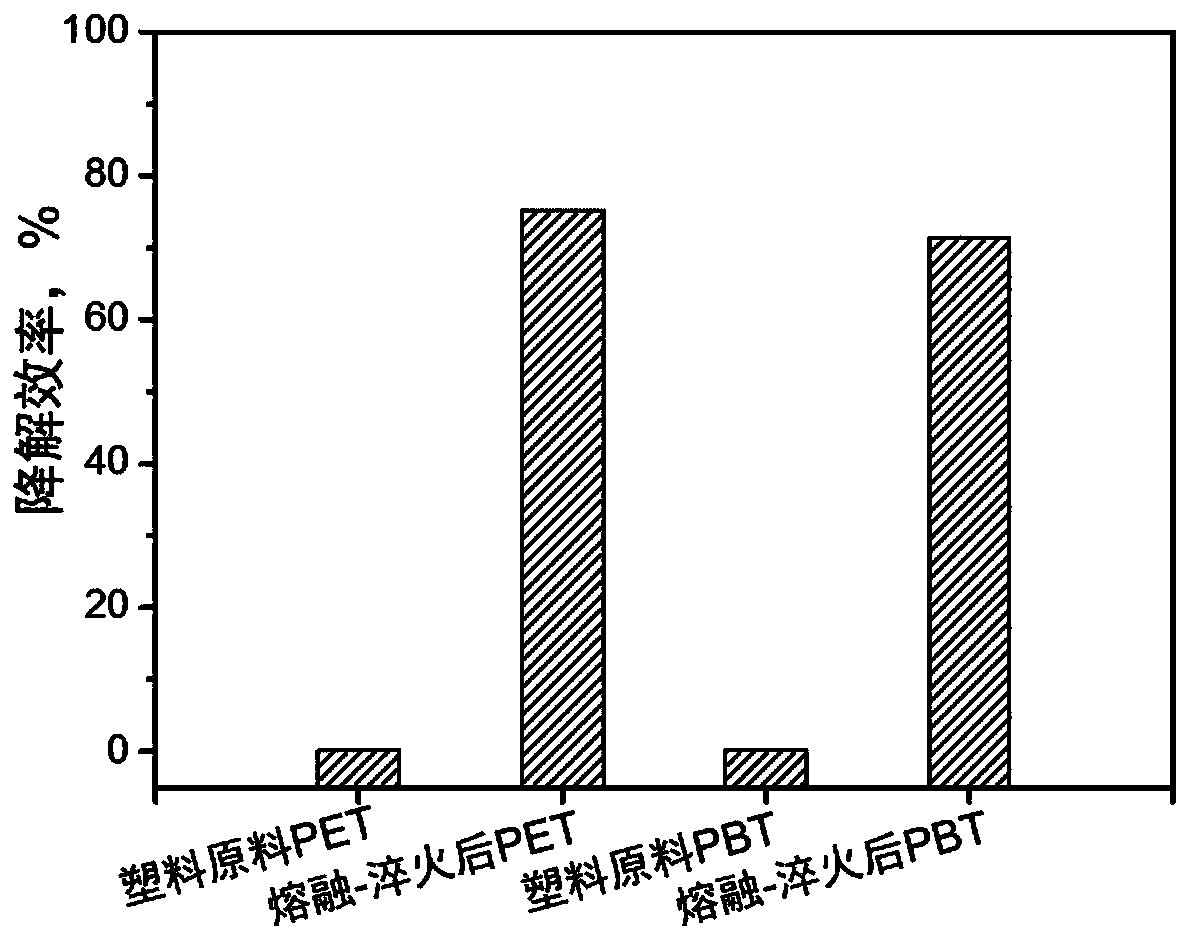

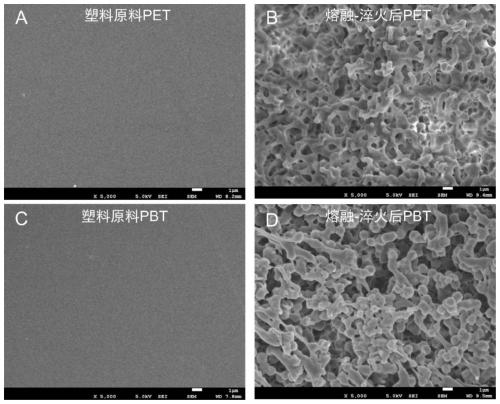

[0054] 1) Preparation of plastic raw materials: Clean polyethylene terephthalate (PET) and polybutylene terephthalate (PBT), etc., cut them to a length less than 5 cm, and dry them for later use. Measure the melting temperature (T) of the crystalline plastic itself m ), glass transition temperature (T g ) and crystallinity: the melting temperature of polyethylene terephthalate (PET) (T m ) is 270°C, the glass transition temperature (T g ) was 69° C. and the degree of crystallinity was 30%. Melting temperature of polybutylene terephthalate (PBT) (T m ) is 224°C, the glass transition temperature (T g ) was 52°C and the degree of crystallinity was 32%.

[0055] 2) Melting treatment: heating and melting the above-mentioned ...

Embodiment 2

[0074] A method for highly efficient biodegradation of crystalline plastics, comprising the steps of:

[0075] The crystalline plastic is polycaprolactam / nylon-6 (PA-6), polyhexamethylene adipamide / nylon-66 (PA-66), polyhexamethylene sebacamide / nylon-610 (PA-610 );

[0076] 1) Preparation of plastic raw materials: polycaprolactam / nylon-6 (PA-6), polyhexamethylene adipamide / nylon-66 (PA-66), polyhexamethylene sebacamide / nylon-610 (PA- 610) cleaned, cut to a length less than 5cm, and dried for later use. Determination of the melting temperature of the crystalline plastic itself (T m ), glass transition temperature (T g ) and crystallinity: melting temperature of polycaprolactam / nylon-6 (PA-6) (T m ) is 220°C, the glass transition temperature (T g) was 55°C and the degree of crystallinity was 35%. The melting temperature of polyhexamethylene adipamide / nylon-66 (PA-66) (T m ) is 267°C, the glass transition temperature (T g ) was 57°C and the degree of crystallinity was 32%...

Embodiment 3

[0096] A method for highly efficient biodegradation of crystalline plastics, comprising the steps of:

[0097] The method for the biodegradation efficiency of the crystalline plastic poly-L-lactic acid (PLLA), its processing steps are as follows:

[0098] 1) Preparation of plastic raw materials: clean poly-L-lactic acid (PLLA), etc., cut to a length less than 5 cm, and dry for later use. Determination of the melting temperature of the crystalline plastic itself (T m ), glass transition temperature (T g ) and crystallinity: the melting temperature of poly-L-lactic acid (PLLA) (T m ) is 175°C, the glass transition temperature (T g ) was 55°C and the degree of crystallinity was 20%.

[0099] 2) Melting treatment: heating and melting the above-mentioned crystalline plastics, setting the melting working temperature parameter of poly-L-lactic acid (PLLA) to 200° C., and setting the melting working time of the above-mentioned plastics to 3 minutes.

[0100] 3) Quenching treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com