Method for starting bioreactor used for treatment of wastewater containing triethyl phosphate

A technology of triethyl phosphate and bioreactor, which is applied in chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., can solve the problems of unbearable and high treatment costs for enterprises, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

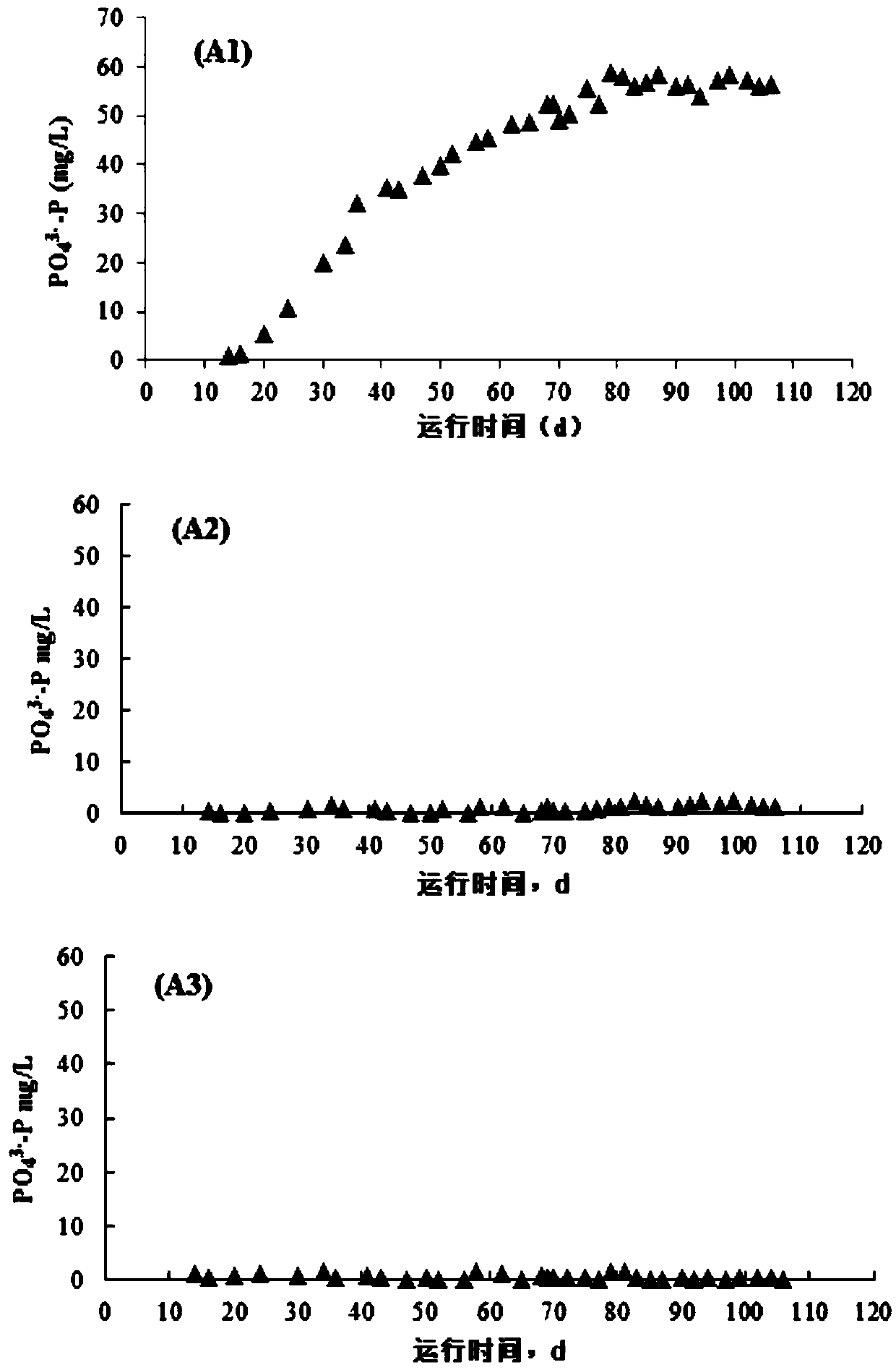

[0017] Start-up of anaerobic bioreactor for treating cytidylic acid wastewater: add 200mL of anaerobic bioreactor from a UASB reactor in a wastewater treatment workshop of a chemical enterprise to each of three 500mL anaerobic reactors (numbered sequentially A1, A2 and A3). Sludge, then add 100mL tap water to each reactor, and then add 100mL No. I, II and III waste water in A1, A2 and A3 anaerobic reactors (see Table 1). The reactor was sealed with a rubber stopper with a conduit, and the other end of the conduit was inserted into a water-sealed bottle to prevent air from being sucked back into the anaerobic reactor. Both the anaerobic reactor and the water-sealed bottle were placed in a constant temperature water bath shaker at 35°C. Change the water once a day, measure the pH value before changing the water, and then turn off the power of the oscillator. After settling for 1-2 hours, the reactor was taken out from the shaker, and 100 mL of the supernatant was poured out, an...

Embodiment 2

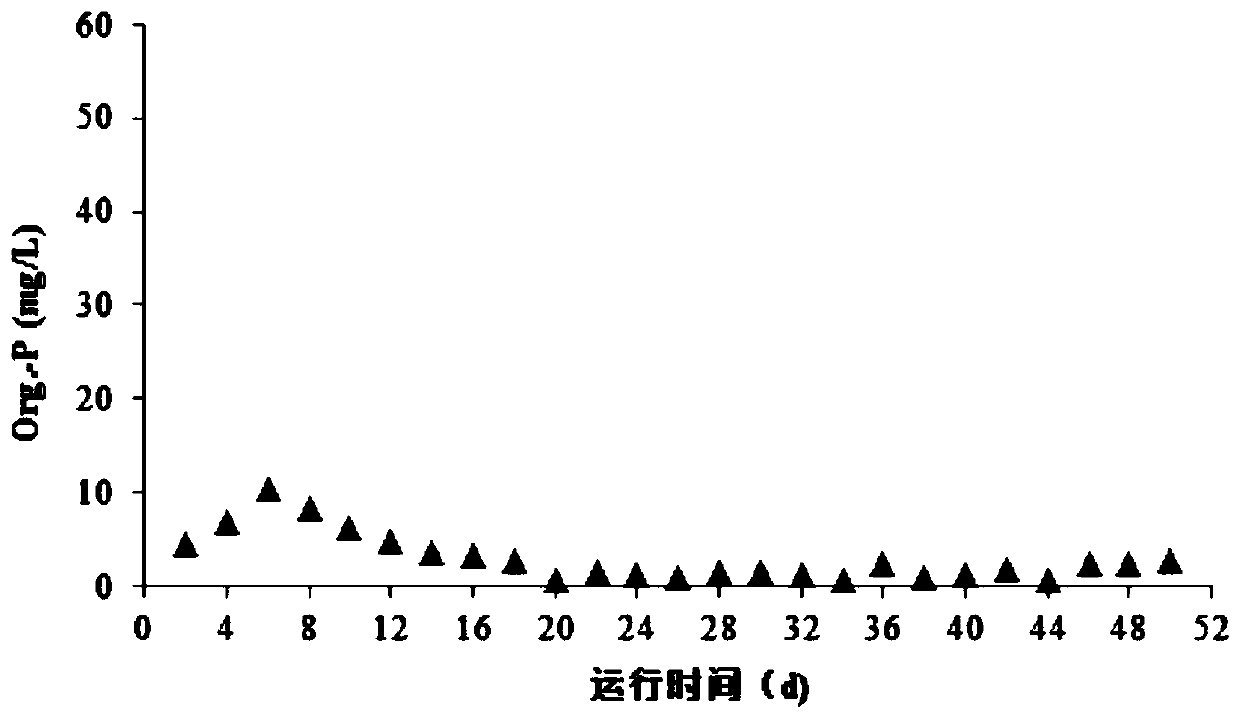

[0023] After the A1 reactor of embodiment 1 runs 106d, its influent is switched to actual cytidylic acid waste water by No. 1 waste water, and other operating conditions all remain unchanged, and test result is as follows figure 2 shown.

[0024] Depend on figure 2 It can be seen that when the influent of A1 reactor is switched from No. I wastewater to actual cytidylic acid wastewater, the concentration of organic phosphorus (Org.-P) in the effluent increases over the first 6 days, but after The concentration of Org.-P in the effluent began to decrease and gradually stabilized. After running for 50 days, the average concentration of Org.-P in the effluent is about 2.9mg / L, and the mineralization rate of organic phosphorus (mainly TEP) in cytidylic acid wastewater is about 95%, which shows that the anaerobic biological method is used to treat cytidine In the case of acid wastewater, as long as the anaerobic reactor is successfully started, the TEP in it can be efficiently d...

Embodiment 3

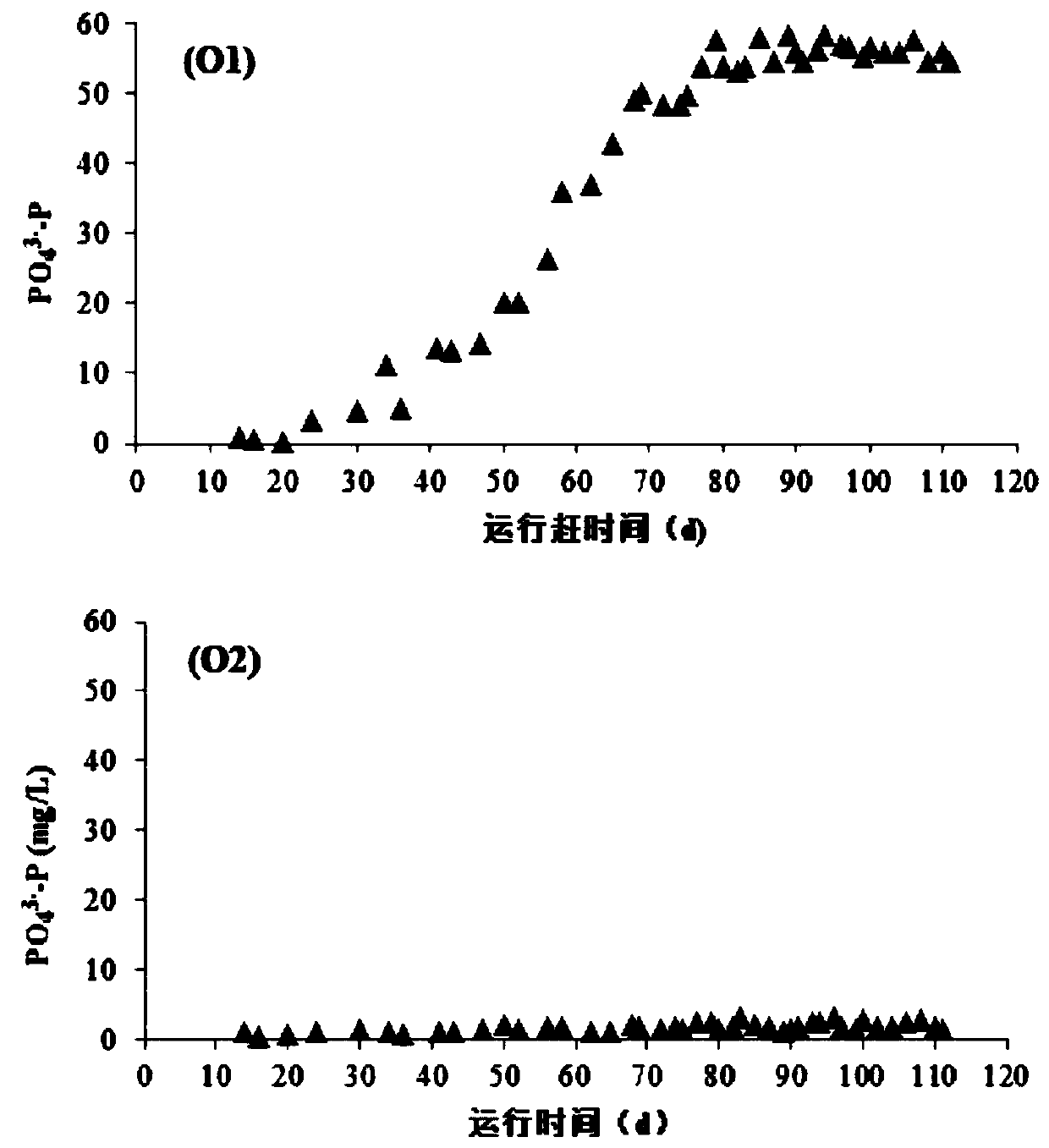

[0026] Start-up of the aerobic bioreactor for treating cytidylic acid wastewater: Add 1300mL of water from the aeration tank of a certain urban sewage treatment plant to each of the three aerobic reactors (numbered O1, O2 and O3) with an effective volume of 2000mL Then add 700mL of No. I, II and III waste water in O1, O2 and O3 aerobic reactors respectively (see Table 1). Turn on the blower, aerate and oxygenate the O1, O2 and O3 aerobic reactors, control the DO concentration to 2-4mg / L, stop the aeration after 6h, let it settle for 2h, and discharge 700mL supernatant from the three reactors respectively liquid, and then add 700mL of No. I, II and III waste water respectively. The operation cycle of O1, O2 and O3 aerobic reactors is 24 hours, of which aeration is 6 hours, sedimentation is 2 hours, the time of water inflow and drainage is very short, and the rest is idle time. Test results such as image 3 shown.

[0027] Depend on image 3 (O1) It can be seen that when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com