Inner barrel rack of washing machine

A washing machine and drum rack technology, applied in the field of household appliances, can solve the problems of heavy weight of cast aluminum tripod, adhesion of washing dirt, long molding cycle, etc., and achieve good anti-rust and anti-corrosion performance, increase overall strength, and simple molding process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

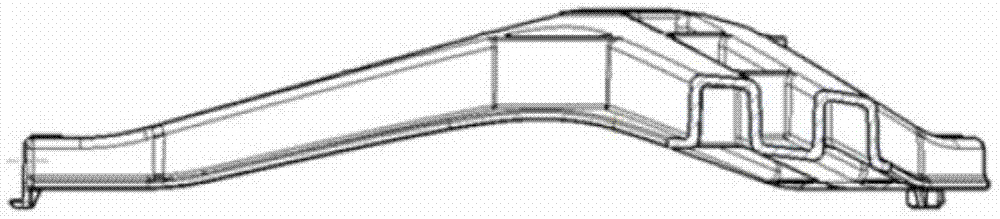

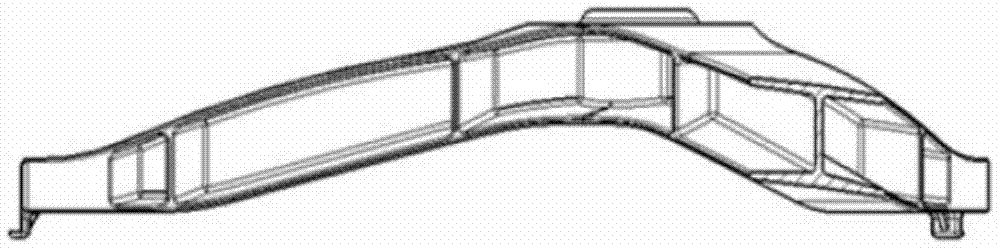

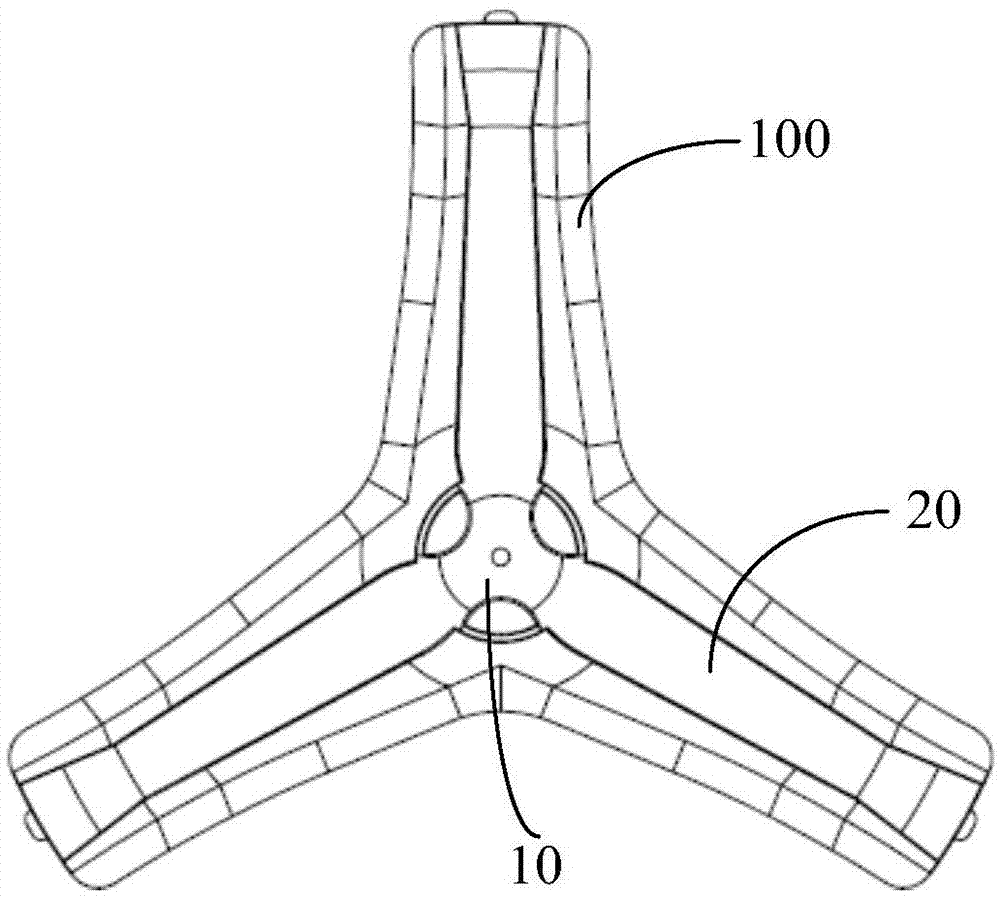

[0027] The invention discloses an inner tube frame of a washing machine. The inner tube frame is fixedly installed on the bottom of the inner tube of the washing machine. The inner tube frame includes a mounting part and an extension part extending outward from the mounting part. A steel shaft assembly is arranged in the middle of the mounting part. , The installation part and the extension part are integrally injection molded.

[0028] Compared with the cast aluminum inner barrel frame in the prior art, the inner barrel frame of the present invention is injection-molded with high-strength plastic particles, and has good antirust and anticorrosion properties.

[0029] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obvious...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Minimum width | aaaaa | aaaaa |

| Maximum width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com